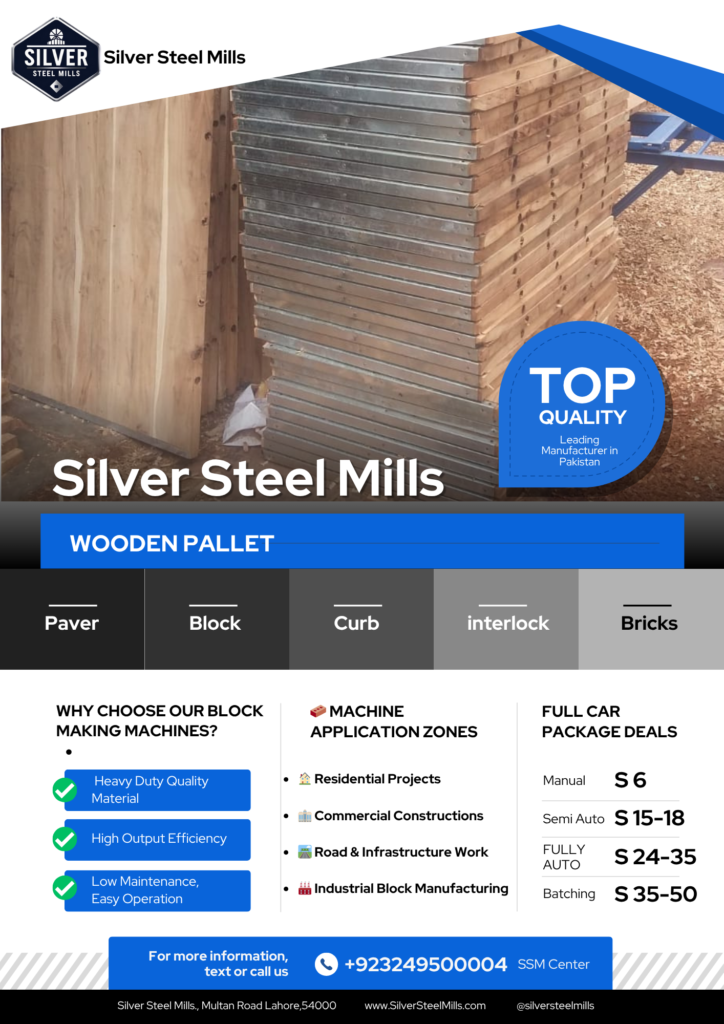

Block Making Machine Pallet Manufacturers in Pakistan: A Spotlight on Silver Steel Mills

In the construction and concrete block manufacturing industry of Pakistan, one component often overlooked but vitally essential is the wooden pallet used in block making machines. These pallets are the backbone of efficient brick, block, and tile production — literally carrying the weight of output on their surface. As the demand for quality concrete blocks rises, so does the need for durable, precisely manufactured pallets. Among the few manufacturers that have made a name in this niche, Silver Steel Mills stands out as a leading pioneer in custom wooden pallet manufacturing for block making machines in Pakistan.

Introduction to Block Making Machine Pallets

Block making machines — whether fully automated or semi-automatic — require reliable and dimensionally stable wooden pallets to carry freshly molded bricks, blocks, pavers, or tiles to the curing areas. These pallets ensure shape integrity, prevent deformation during the handling process, and support uniform curing, all while withstanding moisture, pressure, and vibration cycles during molding.

In the Pakistani market, where the concrete block industry is growing rapidly, pallet quality has become a direct determinant of production efficiency and profitability. This is where Silver Steel Mills plays a critical role.

Silver Steel Mills – Leading Wooden Pallet Manufacturer in Pakistan

Silver Steel Mills (SSM), known for its high-precision engineering and strong foothold in the block machinery sector, has become one of the most trusted names in wooden pallet manufacturing. With a specialized production unit dedicated to custom pallet dimensions, SSM offers a wide range of standard and tailor-made wooden pallets for all types of block making plants.

Whether it’s for manual, semi-automatic, or fully automatic SSM and imported machines, Silver Steel Mills crafts each pallet to perfection — using seasoned hardwood, treated pinewood, or composite wood depending on client requirements.

Why Silver Steel Mills?

Here’s what makes Silver Steel Mills the preferred choice for block machine pallet buyers across Pakistan:

✅ Premium-Quality Materials

SSM uses moisture-treated hardwood, kiln-dried for strength and stability. This prevents warping or cracking during curing, especially in high humidity or water-heavy environments.

✅ Custom Sizes Manufacturing

Unlike standard vendors, Silver Steel Mills specializes in custom-size manufacturing to suit different machine molds and factory layouts. Popular dimensions manufactured by SSM include:

-

26” x 30”

-

30” x 30”

-

30” x 32”

-

30” x 42”

-

35” x 48”

-

36” x 48”

-

30” x 56”

They also offer bespoke sizes tailored to specific client machine setups and product requirements.

✅ High Load-Bearing Capacity

These pallets are engineered to withstand the intensive load of concrete block production — holding thousands of kilograms over multiple cycles per day.

✅ Precision Thickness Control

The thickness and density of the wooden pallets directly impact product quality and machine performance. SSM’s pallets maintain exact dimensional tolerance to ensure perfect alignment with machine ejectors and vibrators.

✅ Affordable and Durable

Despite high-end materials and finishing, Silver Steel Mills keeps pricing competitive — helping startups and large production plants alike to maintain cost-effective operations.

Importance of Quality Wooden Pallets in Block Making Machines

In Pakistan, the growing trend toward automated block manufacturing has made the role of pallets even more crucial. Poor-quality pallets often cause:

-

Cracked or broken blocks

-

Machine misalignment

-

Reduced curing efficiency

-

Increased rejection rates

This leads to operational inefficiencies and higher production costs. By opting for Silver Steel Mills’ precision-engineered wooden pallets, manufacturers can eliminate such issues and boost plant efficiency, reduce waste, and improve product consistency.

Who Needs These Pallets?

Silver Steel Mills caters to:

-

Block machine manufacturers

(e.g., GSM 15, GSM 24, GSM 35, GSM 50 plants) -

Concrete paver/tile producers

-

Construction companies with in-house block production units

-

Tuff tile manufacturers

-

Government contractors and PWD units engaged in infrastructure projects

Technical Highlights of SSM Pallets

| Feature | Specification |

|---|---|

| Material | Treated hardwood, pinewood |

| Thickness | Custom (standard: 35–50 mm) |

| Weight Bearing Capacity | 800–1500 kg |

| Moisture Resistance | Yes (treated and sealed) |

| Edge Finishing | Rounded or chamfered (as per machine) |

| Compatibility | GSM, imported, custom mold machines |

| Lifespan | 1.5–3 years (based on usage) |

Large-Scale Supply & Timely Delivery Across Pakistan

Silver Steel Mills has the infrastructure to mass-produce and supply pallets across Lahore, Faisalabad, Karachi, Peshawar, Rawalpindi, Quetta, Multan, and other cities. Whether you need 1,000 units or 50,000, SSM’s robust supply chain ensures timely dispatch with professional packaging and loading services.

Environmental & Economic Value

Wooden pallets manufactured by SSM are also eco-friendly. The company emphasizes using renewable wood sources, offering recycling options, and encouraging clients to repair rather than discard old pallets. This approach not only benefits the environment but also offers a cost-saving alternative for frequent users.

Customized Branding and Laser Engraving Options

Silver Steel Mills also provides branding services on pallets, including:

-

Laser engraving of company logos

-

Serial numbering for inventory tracking

-

Color coding for size differentiation

This adds professionalism and operational control to your block production unit.

Heavy Duty Wooden Pallets for Block Making Machines – Strengthened with Galvanized Steel and Iron Rods

In Pakistan’s block manufacturing and concrete batching industry, the quality of pallets directly affects production efficiency and product durability. One of the most reliable options in this domain is the heavy-duty pallet made from Kikar ki Lakri, further enhanced with U-shaped galvanized steel support and central reinforcement using iron rods and male-female wooden joints.

Why Use Kikar Ki Lakri for Pallets?

Kikar wood (Acacia) is known for its hardness, moisture resistance, and long-lasting strength. Compared to other softwood options, Kikar offers superior load-bearing capacity, making it ideal for heavy industrial applications like concrete block manufacturing.

Galvanized Steel U-Support for Pallet Strength

On both sides of the pallet, galvanized steel U-channel brackets are fixed, ensuring structural stability and edge protection. These U-steel channels prevent warping and protect the wood from splitting due to repetitive load impacts from block machines or tile presses.

Central Male-Female Wooden Joint with Iron Rod (Sarya)

In the center, a precision-cut male and female interlocking joint is installed, bonded with heavy-duty iron rods (sarya). This joint increases the torsional strength of the pallet and helps it endure high compression and vibrations during block compaction and demolding.

Applications and Compatibility

These pallets are highly recommended for:

-

Automatic block making machines in Pakistan

-

Manual block and brick presses

-

Paver tile plants and tuff tile machines

-

Fly ash brick machines

-

Concrete batching plant block handling systems

-

Block machine pallet in Pakistan

-

Concrete block machine pallet price

-

Wooden pallet for tuff tile machine

-

Kikar wood pallet for block making

-

Galvanized steel pallet for brick press

-

Heavy-duty industrial pallets Pakistan

-

Fly ash brick pallet reinforced with steel

-

Iron rod reinforced block machine pallet

Final Thoughts

Choosing the right pallet is essential for high productivity and minimal wastage in block and paver production. These Kikar wooden pallets with steel reinforcements from Silver Steel Mills offer both longevity and mechanical strength, ensuring efficient use in all types of block making setups across Pakistan.

Conclusion: Silver Steel Mills — The Backbone of Block Machine Productivity

In conclusion, as Pakistan’s construction industry shifts to modern, high-speed block manufacturing systems, the demand for high-quality, custom-sized wooden pallets is rapidly increasing. Silver Steel Mills remains at the forefront of this transition, providing a critical solution that enhances machine output, product quality, and cost efficiency.

For anyone investing in block making machines, whether new or existing setups, choosing the right pallet manufacturer is a game-changer. And in Pakistan, Silver Steel Mills is the name to trust — delivering the strength, reliability, and customization that today’s block plants require.

Contact Silver Steel Mills

v

🌐 Website: https://silversteelmills.com

*📦 Nationwide Delivery | Customized Orders | Bulk Supply Discounts Available