How to Start a Concrete Block Making Business in Pakistan

Introduction

Starting a concrete block making business in Pakistan can be an immensely profitable venture due to the country’s rapidly growing construction industry. With urbanization on the rise and the demand for affordable housing, durable building materials like concrete blocks are becoming essential. This business not only provides an opportunity for long-term financial success but also offers the chance to contribute to the development of sustainable and eco-friendly construction solutions.

In this guide, we will walk you through all the essential steps to set up a concrete block making business in Pakistan, including market research, necessary equipment, production processes, legal requirements, and how to create a solid business plan for success.

1. Market Research and Feasibility

Before diving into the concrete block making business, it’s crucial to conduct thorough market research. This will help you understand the demand, identify your target market, and analyze the competitive landscape.

Understanding the Market Demand

The construction industry in Pakistan is booming, especially in urban areas like Karachi, Lahore, Islamabad, and Rawalpindi, with numerous residential and commercial projects. The demand for concrete blocks, particularly for building homes, offices, schools, and hospitals, is high.

Key factors driving the demand include:

- Urbanization: As more people migrate to urban areas, the need for affordable housing increases, thus driving demand for building materials like concrete blocks.

- Sustainability: With growing environmental awareness, eco-friendly materials like fly ash concrete blocks are in demand, making it a profitable niche for businesses.

- Government Housing Projects: The Pakistani government has launched numerous affordable housing schemes, boosting demand for quality concrete blocks.

Competitive Analysis

The concrete block industry in Pakistan is competitive, with several established players and newcomers. However, there is still room for new entrants who offer high-quality products at competitive prices. Key competitors typically range from large manufacturers to smaller local producers.

To succeed in this competitive market, you must differentiate yourself by offering:

- Superior quality: Consistency in size, shape, and strength of the blocks is critical.

- Affordable pricing: Offering competitive prices while maintaining quality.

- Timely delivery: Ensuring reliable supply to construction sites can give you a significant edge.

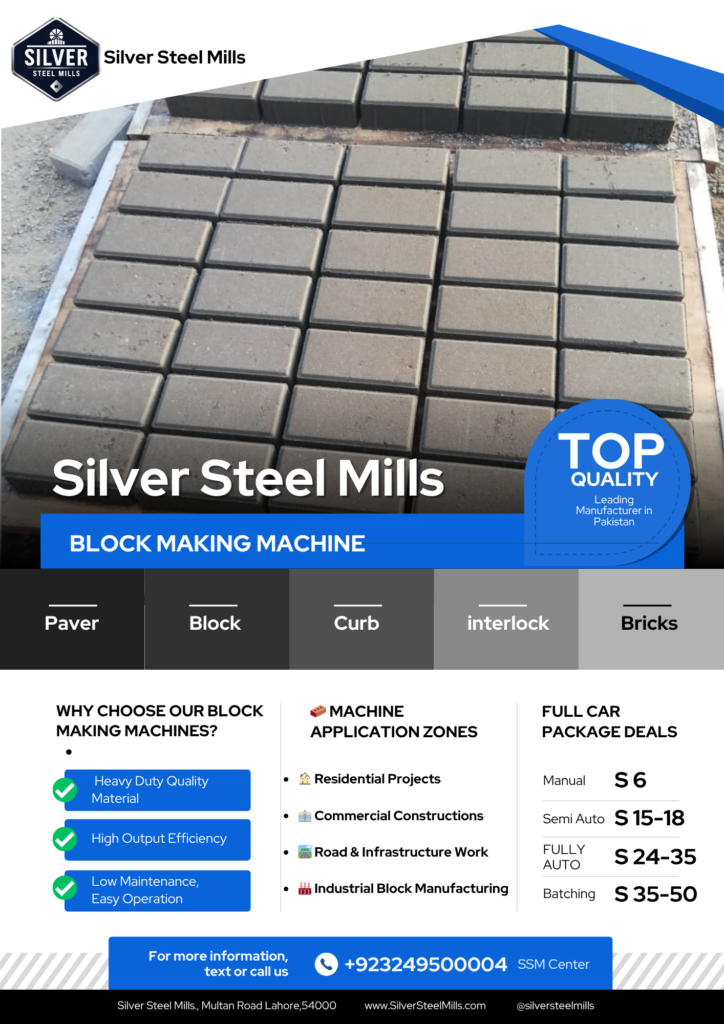

2. Required Equipment and Machinery

The concrete block making business requires specific machinery to produce high-quality blocks efficiently. There are various types of equipment available, ranging from manual to fully automated systems. Here’s a breakdown of the essential equipment you’ll need:

Types of Machines:

- Manual Block Making Machines: These machines require human effort to operate but are suitable for small-scale production.

- Semi-Automatic Block Making Machines: These machines offer a balance between manual labor and automation, increasing efficiency while keeping costs relatively low.

- Fully Automatic Block Making Machines: Fully automated machines are best for large-scale production and high-volume output. They offer superior efficiency, uniformity, and quality control.

Key machinery for production:

- Concrete Mixer: To mix cement, sand, and water, producing a uniform mixture for the blocks.

- Molding Machine: A machine that shapes the concrete mixture into blocks of various sizes and shapes.

- Hydraulic Press: This is used to compact the blocks, giving them the required density and strength.

- Curing Chamber: After the blocks are molded, they need to cure for a specific period to gain strength. This chamber provides the ideal conditions for curing.

Choosing the Right Equipment

Choosing the right machinery depends on your budget, production scale, and desired output. For smaller businesses, manual and semi-automatic machines are ideal, while larger businesses may require fully automated machines to meet high demand.

Key points to consider:

- Capacity: The number of blocks the machine can produce per hour or day.

- Durability: Machines should be durable and capable of continuous operation.

- After-sales service: Ensure the manufacturer offers strong after-sales support for maintenance and spare parts.

3. Setting Up the Business

Setting up a concrete block making business in Pakistan requires careful planning and investment. This section outlines the critical steps involved in setting up the business.

Choosing a Location

The location for your concrete block factory is critical to your business’s success. It should be accessible to raw materials, markets, and transportation routes. A good location offers:

- Easy access to raw material suppliers (sand, cement, aggregates).

- Proximity to construction sites or distributors who will buy your blocks.

- Sufficient space for machinery, storage, and a curing area for blocks.

Space Requirements

For a small-scale business, you may need approximately 1,000-2,000 square feet of space, while for large-scale production, this can extend to several acres. The factory must have:

- Production area: For machinery and the manufacturing process.

- Storage: For raw materials and finished blocks.

- Office: For managing the administrative side of the business.

- Loading/Unloading Dock: For transporting materials and finished products.

4. Understanding Raw Materials

Raw materials are the core of the concrete block production process. The key ingredients used in making concrete blocks are:

- Cement: The primary binding agent that holds the concrete mixture together.

- Sand: A crucial ingredient that determines the texture and strength of the block.

- Gravel/Coarse Aggregate: Provides bulk and increases the block’s strength.

- Fly Ash: A waste product from power plants that can be used to create more eco-friendly blocks. Fly ash blocks are in high demand due to their sustainability.

Raw Material Sourcing

To ensure consistent production, it’s essential to have reliable suppliers for these materials. The cost of these materials can vary depending on the quality, availability, and location of the supplier. Establishing strong relationships with suppliers will help ensure timely deliveries and competitive pricing.

Material Testing

Quality control is crucial in ensuring that the raw materials meet the necessary standards. You should perform routine testing for:

- Cement quality: Ensure it meets the required strength and durability specifications.

- Sand and aggregate: These should be free from impurities and graded correctly.

- Fly ash: For eco-friendly blocks, ensure it meets environmental standards.

5. Production Process

The production process involves several steps that transform raw materials into finished concrete blocks. This includes mixing, molding, pressing, and curing.

Step 1: Mixing the Concrete

The first step is to mix the raw materials—cement, sand, aggregates, and water—into a uniform mixture. The consistency of the mixture is critical for the quality of the blocks.

Step 2: Molding

Once the mixture is ready, it is poured into molds that determine the shape and size of the concrete blocks. The molds can be customized to produce various sizes of blocks, including standard and interlocking types.

Step 3: Pressing

After molding, the blocks are pressed using hydraulic presses to ensure they have the right density and strength. This process also helps compact the mixture for uniformity.

Step 4: Curing

After the blocks are molded and pressed, they must be cured to ensure they achieve the necessary strength. The curing process can take anywhere from 7 to 28 days, depending on the environmental conditions and the type of block.

6. Quality Control and Testing

Ensuring the quality of your concrete blocks is essential for long-term success. High-quality blocks will ensure customer satisfaction and build your reputation in the market.

Key Quality Control Steps:

Curing and Drying: Proper curing is crucial for achieving strength, so monitor the temperature and humidity during the curing process.

Block Strength Testing: Ensure the blocks meet the required compressive strength standards by performing tests.

Size and Shape Consistency: Ensure the blocks are uniform in size and shape, which is important for construction applications.

7. Marketing and Sales Strategy

To succeed in the concrete block making business, having a strong marketing and sales strategy is crucial. Effective marketing will help you attract customers and build a strong brand presence in the market. Here are the essential strategies you can adopt:

1. Identifying Your Target Market

Your target market consists of various stakeholders involved in the construction industry. This includes:

- Contractors and Builders: The primary customers for concrete blocks, as they require bulk quantities for large projects.

- Architects and Engineers: Professionals who recommend building materials to their clients.

- Retailers/Distributors: These middlemen will sell your concrete blocks to smaller construction projects.

- Government Projects: Local or national government projects that require building materials for public infrastructure.

Focusing on these customer segments allows you to tailor your marketing efforts accordingly.

2. Building a Brand Presence

Branding plays a vital role in attracting customers. Here’s how you can build your concrete block business brand:

- Logo and Company Identity: Develop a professional logo and company identity that reflects the quality and reliability of your concrete blocks.

- Website Development: Create an informative and user-friendly website where customers can view your products, prices, and contact information.

- Social Media Marketing: Utilize platforms like Facebook, Instagram, and LinkedIn to showcase your projects, demonstrate the strength and durability of your blocks, and engage with your audience.

3. Digital Marketing

In today’s competitive landscape, digital marketing is a powerful tool. Consider the following:

- SEO (Search Engine Optimization): Optimize your website for keywords like “concrete blocks for sale in Pakistan”, “affordable concrete blocks”, or “fly ash concrete blocks”. This will help you rank higher on Google and attract more traffic.

- Pay-Per-Click (PPC) Ads: Run targeted ads on Google and social media to promote your products.

- Content Marketing: Develop blogs and articles around construction tips, the benefits of concrete blocks, and sustainable construction. This positions you as an industry thought leader and can drive organic traffic to your website.

4. Offline Marketing

Offline marketing still plays an important role in a local market like Pakistan:

- Trade Shows and Conventions: Participate in industry trade shows, exhibitions, and conferences to meet potential clients and showcase your products.

- Brochures and Flyers: Distribute these to construction sites, retail outlets, and through business partnerships with architects and contractors.

- Local Advertising: Invest in local advertising via newspapers, radio, or billboards in the areas you serve.

5. Building Customer Relationships

To retain customers and encourage repeat business, focus on building strong relationships:

- Customer Service: Provide excellent customer service by addressing concerns, offering warranties, and ensuring timely deliveries.

- Loyalty Programs: Offer discounts or incentives to long-term clients who regularly purchase blocks from you.

8. Legal and Regulatory Considerations

Starting a concrete block business in Pakistan involves adhering to several legal and regulatory requirements. These ensure that your business operates smoothly and legally.

1. Business Registration

Before starting the business, you must register your company with the Securities and Exchange Commission of Pakistan (SECP). Choose an appropriate legal structure, such as a sole proprietorship, partnership, or private limited company.

2. Obtaining Licenses and Permits

You will need several licenses and permits to operate:

- Factory License: From local authorities to operate a manufacturing plant.

- Environmental Compliance: Ensure your business complies with environmental standards, particularly if you’re using materials like fly ash.

- Health and Safety: Comply with health and safety regulations to protect workers and ensure that the workplace is safe.

3. Labor Laws

The labor force in your concrete block factory must be properly managed under Pakistan’s labor laws. This includes compliance with:

- Employee Welfare: Provide a safe working environment, pay fair wages, and ensure benefits such as health insurance.

- Minimum Wage Laws: Adhere to the legal minimum wage for factory workers.

4. Taxes and VAT

You will need to obtain a Taxpayer Identification Number (TIN) from the Federal Board of Revenue (FBR). Depending on your scale, you may also need to charge VAT (Value Added Tax) on your sales.

9. Financial Planning and Cost Estimation

Financial planning is key to understanding the potential profitability of your concrete block making business. Let’s break down the major costs involved and how to manage them:

1. Initial Investment

The initial investment includes the costs of land, machinery, and setting up your factory. Here’s a breakdown:

- Land Purchase or Lease: The cost of land will vary based on location. It’s essential to choose a site near raw material suppliers and construction sites.

- Machinery: Invest in quality machinery like block-making machines, mixer machines, and hydraulic presses. The cost of machines can range from a few hundred thousand to several million rupees, depending on the type and capacity.

- Factory Setup: This includes construction costs, infrastructure development, and installation of machinery.

2. Operating Costs

Once the business is operational, you’ll need to account for:

- Raw Materials: Cement, sand, fly ash, and aggregates are ongoing costs that fluctuate based on market prices.

- Labor: Salaries of employees, including machine operators, maintenance workers, and administrative staff.

- Utilities: Water, electricity, and fuel are essential for running the machines and factory operations.

- Transportation: Delivery costs to customers or construction sites.

3. Profit Margins

The pricing of concrete blocks depends on the cost of raw materials and operational expenses. You must ensure that your pricing is competitive, but still allows for a reasonable profit margin.

4. Financial Projections

Develop financial projections for the first 3-5 years of your business. Include:

- Revenue Projections: Estimate sales based on the number of blocks you can produce and sell.

- Expense Projections: Account for fixed and variable expenses.

- Break-Even Analysis: Determine how long it will take for your business to become profitable.

10. Operations and Maintenance

Proper operations and maintenance practices are crucial for ensuring the smooth running of your business and the longevity of your machinery.

1. Production Planning

Develop a production schedule to ensure you meet demand without overproduction. Use inventory management software to track raw materials and finished blocks.

2. Maintenance of Equipment

Regular maintenance is essential for minimizing downtime. Set up a maintenance schedule for each piece of equipment, and train staff to handle minor repairs.

3. Staff Management

Hire experienced staff to run the machinery and manage production. You’ll need workers for various roles such as:

- Machine Operators

- Quality Control Inspectors

- Maintenance Technicians

- Administrative Staff

Provide training for all employees to ensure they understand the production processes and safety protocols.

11. Scalability and Future Growth

Once your business is up and running successfully, you may want to scale up. Here are strategies for expansion:

1. Expanding Production Capacity

As demand grows, you may need to invest in larger machines or additional production lines. Assess the capacity of your current machines and consider purchasing more automated equipment to increase output.

2. Entering New Markets

Expand into new geographic regions within Pakistan or even internationally. Look into exporting your concrete blocks to neighboring countries like Afghanistan or Middle Eastern nations.

3. Diversifying Products

You can diversify your product offerings by producing different types of concrete blocks, such as:

- Interlocking Blocks

- Paving Stones

- Architectural Blocks

12. Conclusion

Starting a concrete block making business in Pakistan is a highly lucrative venture, especially in the context of the country’s growing construction industry. With the right planning, investment, and strategy, you can create a business that not only thrives locally but also has the potential to scale and expand internationally.

By focusing on high-quality production, effective marketing, and adhering to legal and regulatory standards, your business can succeed in an increasingly competitive market.

13. Sustainability and Environmental Considerations

In today’s business environment, sustainability is crucial for long-term success, especially in industries like concrete block production. As the world moves towards environmentally conscious practices, it’s important to ensure that your concrete block business aligns with sustainable methods. This not only helps in reducing your environmental impact but also enhances your brand reputation among environmentally conscious consumers.

1. Eco-Friendly Production Practices

- Using Fly Ash in Concrete Blocks: One of the most environmentally friendly practices in concrete block production is using fly ash, a byproduct from power plants. Fly ash can replace a portion of cement in concrete mixes, significantly reducing CO2 emissions associated with cement production.

- Recycling Waste Materials: You can incorporate recycled materials like crushed concrete or glass into your concrete mix. This practice not only reduces waste but also lowers the cost of raw materials.

- Energy Efficiency: Ensure that your production processes are energy efficient. Invest in energy-efficient machinery, and consider utilizing renewable energy sources like solar panels to power your operations.

2. Waste Management

Concrete production can generate waste in the form of discarded concrete, dust, and excess materials. Proper waste management is essential for maintaining a clean factory and adhering to environmental regulations. Consider the following:

- Concrete Waste Recycling: Set up a system for recycling excess concrete that doesn’t make it into the final blocks. This can be crushed and reused in the production of new blocks.

- Dust Control: Implement systems to manage dust produced during mixing, molding, and drying. This can include water sprays or filtration systems that minimize the release of particulate matter into the environment.

- Wastewater Treatment: Wastewater generated from the curing process should be treated before being disposed of to prevent contamination of surrounding water bodies.

3. Compliance with Environmental Laws

Pakistan has several laws and regulations aimed at protecting the environment. Ensure that your business complies with these regulations, including:

- Environmental Protection Agency (EPA) regulations for the construction industry.

- Sustainable Resource Use: Obtaining certifications for sustainable practices can not only boost your market position but can also attract eco-conscious customers and investors.

14. Risk Management

Running a concrete block manufacturing business involves various risks, ranging from financial to operational challenges. To ensure the long-term success and stability of your business, it’s essential to develop a comprehensive risk management strategy.

1. Identifying Business Risks

Some common risks associated with the concrete block manufacturing business include:

- Fluctuations in Raw Material Prices: The prices of raw materials like cement, sand, and aggregates can fluctuate based on supply and demand. A sudden increase in prices can erode profit margins.

- Equipment Breakdown: Machinery breakdowns can lead to production delays, which in turn affects delivery timelines and customer satisfaction.

- Market Competition: Increased competition from local manufacturers or imports can impact your market share, especially if you don’t differentiate your product or offer competitive pricing.

- Economic Downturns: A recession or downturn in the construction sector can reduce the demand for concrete blocks, affecting overall sales.

2. Mitigation Strategies

To manage these risks effectively, consider implementing the following strategies:

- Diversification: Diversifying your product line to include different types of concrete blocks (e.g., interlocking, decorative) or venturing into new markets (e.g., export) can reduce reliance on a single product or market.

- Price Contracts with Suppliers: Negotiating long-term contracts with your raw material suppliers can help lock in stable prices and avoid sudden price increases.

- Regular Equipment Maintenance: Setting up a maintenance schedule and having spare parts readily available for critical equipment can help minimize downtime caused by breakdowns.

- Insurance: Consider purchasing insurance to protect your business from unforeseen risks, including property damage, equipment breakdowns, and business interruption.

3. Financial Risk Management

Financial risks, such as cash flow issues, can derail your business. To mitigate financial risks:

- Maintain a Cash Reserve: Keep a cash reserve to handle any unforeseen expenses or delays in payments from customers.

- Invoice Promptly: Ensure that your sales team invoices customers promptly and follows up on overdue payments to maintain a healthy cash flow.

- Secure Financing: For large-scale expansion, consider securing financing through loans or investors. However, ensure that your business model and cash flow projections support the repayment of these funds.

15. Conclusion

Starting a concrete block making business in Pakistan is a promising and profitable venture, driven by the ever-growing demand for construction materials. By following the steps outlined in this article, from market research to financial planning and sustainability considerations, you can establish a successful business that not only meets the needs of the construction industry but also grows sustainably in the long term.

The concrete block industry offers vast opportunities for those willing to invest in quality, innovation, and customer satisfaction. As Pakistan’s construction sector continues to flourish, the demand for reliable, durable, and cost-effective concrete blocks will keep rising. By adhering to the best practices outlined here and staying committed to quality, your business can stand out in the competitive market and achieve lasting success.

Next Steps You Can Take:

- Create an Action Plan:

- Break down the guide into smaller, actionable tasks. Prioritize tasks such as setting up a legal structure, registering your business, acquiring machinery, and developing marketing strategies.

- Develop a Business Plan:

- Based on the financial planning and market research sections, create a detailed business plan that includes your goals, target market, financial projections, and marketing strategies.

- Secure Funding:

- If your financial projections require additional funding, you may want to approach banks, investors, or government funding programs to get a loan or investment.

- Build a Team:

- Start building your team by hiring key roles such as machine operators, quality control inspectors, and salespeople who can help run and expand the business.

- Find Suppliers and Build Relationships:

- Begin sourcing raw materials and building relationships with suppliers for cement, sand, fly ash, and other materials needed for production.

- Design Your Marketing Materials:

- Work on your branding and marketing materials. Create a professional logo, brochures, and a website. You might also want to start running social media ads or Google ads to attract initial customers.

- Implement Legal Compliance:

- Make sure your business complies with all local regulations, including environmental standards, safety laws, and taxation. This will ensure your business avoids legal issues in the future.

- Monitor Operations and Adjust:

- Once the business is up and running, regularly monitor your operations, identify areas for improvement, and make adjustments as needed to ensure optimal performance.

- Expand Your Product Range:

- Once you’ve established your concrete block business, consider expanding your product offerings. Explore different types of blocks, such as decorative, paving, or interlocking blocks, and assess the market demand for these products.

- Scale and Innovate:

- As demand grows, consider scaling your business by acquiring more advanced machinery, expanding to new locations, or offering custom-made concrete products to differentiate your business.

16. Advanced Business Growth Strategies

At this point, your concrete block business may be up and running. However, it’s crucial to focus on strategies that will allow you to scale efficiently and drive long-term growth. Here are advanced business strategies you can apply:

1. Innovation and Product Diversification

Innovation is essential for staying ahead in a competitive market. While your focus may be on concrete block production, you can explore other profitable products within the same industry:

- Interlocking Concrete Blocks: These are designed to lock together without the need for mortar, making them easier and quicker to use for construction projects.

- Decorative Concrete Blocks: This product targets the aesthetic side of construction, suitable for fences, walls, and other decorative features in residential or commercial properties.

- Pavers: Concrete pavers are highly sought after for landscaping and urban planning, especially in projects like walkways, driveways, and patios.

- Eco-friendly Alternatives: Offering green alternatives like blocks made from recycled materials or fly ash will not only help attract environmentally-conscious customers but also give you an edge over competitors.

- Custom Concrete Products: Develop customized products for large-scale projects, like custom-sized blocks or blocks with specific designs for certain construction needs.

2. Technology Adoption

Incorporating advanced technology into your operations can significantly improve efficiency and reduce costs. Here are ways technology can enhance your concrete block production business:

- Automation in Production: Invest in automated machinery for tasks like mixing, molding, and curing. Automation reduces labor costs and ensures consistency in the production process.

- Smart Manufacturing: Implement Internet of Things (IoT) sensors on your machines to monitor their performance, track production output, and predict maintenance needs. This will reduce downtime and increase productivity.

- Supply Chain Management Software: Use enterprise resource planning (ERP) systems to manage inventory, raw material procurement, sales, and customer relationships. An ERP system can help streamline your operations and improve decision-making.

- Data Analytics: Use data analytics to track your sales, customer preferences, and production patterns. Analyzing this data will allow you to optimize your product offerings and improve business operations.

3. Expansion into New Markets

To grow your business, consider expanding into new geographic markets. Here are a few strategies for expansion:

- Target Regional Markets: Once your business is established locally, look to expand regionally within Pakistan. Look for areas where construction activities are booming and where there is a demand for concrete blocks.

- Exporting: Exporting concrete blocks to neighboring countries such as Afghanistan, India, or Middle Eastern nations can significantly increase your sales. Before expanding internationally, it’s essential to study the demand and logistics involved.

- Franchise or License: If your business model proves successful in your region, you could consider franchising or licensing your operations to others in different regions. This will allow you to expand quickly without taking on all the risks and capital expenses yourself.

4. Strategic Partnerships and Collaborations

Creating partnerships with key players in the construction industry can provide you with access to new customers and increase sales. Consider the following collaborations:

- Partnership with Builders and Contractors: Forming strong relationships with large-scale contractors, builders, and real estate developers will help you secure bulk orders.

- Collaborating with Architects and Designers: Architects and designers play a crucial role in recommending building materials. Offer them incentives to specify your concrete blocks in their designs.

- Supply Agreements with Retailers: Partner with local building material retailers to distribute your concrete blocks to a wider audience.

17. Financial Planning for Expansion

As you grow your business, you’ll need to plan for additional capital and reinvest your profits. Here are financial strategies for scaling your business:

1. Securing Investment or Loans

Expanding your production capacity, buying additional equipment, or entering new markets will require capital. Here’s how you can secure funding:

- Bank Loans: Approach local banks or financial institutions for loans to finance your expansion. Have a solid business plan and financial projections ready to present.

- Venture Capital or Angel Investors: If you plan to scale quickly or expand into new markets, venture capitalists or angel investors may be interested in investing in your business.

- Government Grants and Subsidies: In some cases, the government provides funding or subsidies to businesses that focus on sustainable practices or job creation. Research available programs that may support your expansion plans.

2. Cost Management and Profit Margins

As your business scales, you’ll need to ensure that you maintain healthy profit margins:

- Negotiate with Suppliers: Secure long-term contracts with suppliers to lock in favorable prices for raw materials, reducing the impact of market fluctuations.

- Reduce Operational Costs: Streamline your production process, reduce waste, and implement energy-efficient machinery to lower costs.

- Increased Sales Volume: Scaling your business will allow you to sell in larger volumes, which can reduce the per-unit cost of production and increase your profit margins.

18. Sustainability and Corporate Social Responsibility (CSR)

As your business grows, adopting a strong sustainability and Corporate Social Responsibility (CSR) strategy can further enhance your reputation and strengthen your brand.

1. Environmentally Friendly Practices

- Use Sustainable Materials: Continue to explore and incorporate eco-friendly materials in your blocks, like fly ash or recycled aggregate.

- Carbon Footprint Reduction: Implement energy-efficient practices, such as using solar energy or other green technologies, to minimize your carbon footprint.

- Waste Reduction: Reduce waste through recycling and repurposing materials, and ensure that your production facility minimizes environmental harm.

2. Community Engagement and Support

Engage with the local community through initiatives like:

- Job Creation: Employ local workers and offer training programs to improve skills and enhance career growth opportunities.

- Supporting Local Causes: Donate a portion of your profits to local charities or sponsor community projects. This can build goodwill and foster long-term customer loyalty.

19. Future Growth and Innovation

Looking ahead, your business can evolve through continuous innovation and exploring new growth opportunities:

1. Expanding Product Lines

As mentioned, introducing new products such as pre-cast concrete products, decorative blocks, or concrete paving slabs can help you cater to a broader market. Innovations like 3D-printed concrete could also be explored as a futuristic approach.

2. Digital Transformation

Adopting a digital-first approach in terms of marketing, customer service, and operations can position your business as a leader in the industry. Utilize online marketplaces, e-commerce platforms, or even mobile apps for seamless ordering and customer service.

3. Diversification

Explore diversification into other construction-related sectors such as ready-mix concrete production, cement manufacturing, or building materials supply.

20. Conclusion

Starting and scaling a concrete block making business in Pakistan is a rewarding venture, especially given the expanding demand in the construction sector. By focusing on innovation, technology adoption, and strategic partnerships, you can position your company for success in a competitive market.

Long-term growth will depend on your ability to stay adaptable, adopt sustainable practices, and leverage digital tools to meet market demands. With careful planning, financial discipline, and strategic risk management, your concrete block business can thrive and become a leader in the industry.