Description

The demand for paving blocks within the building trade has seen vital development in Pakistan over the previous decade. These blocks are extremely valued for his or her sturdiness, aesthetic enchantment, and practicality in a wide range of out of doors purposes comparable to roads, sidewalks, driveways, and parking areas. In case you are contemplating coming into the paving block manufacturing trade or seeking to improve your equipment, understanding the pricing, specs, and different essential components for paver block machines in Pakistan is crucial. On this article, we are going to present an in-depth take a look at the options, pricing, specs, use circumstances, advantages, FAQs, and a complete shopping for information for paver block machines obtainable in Pakistan.

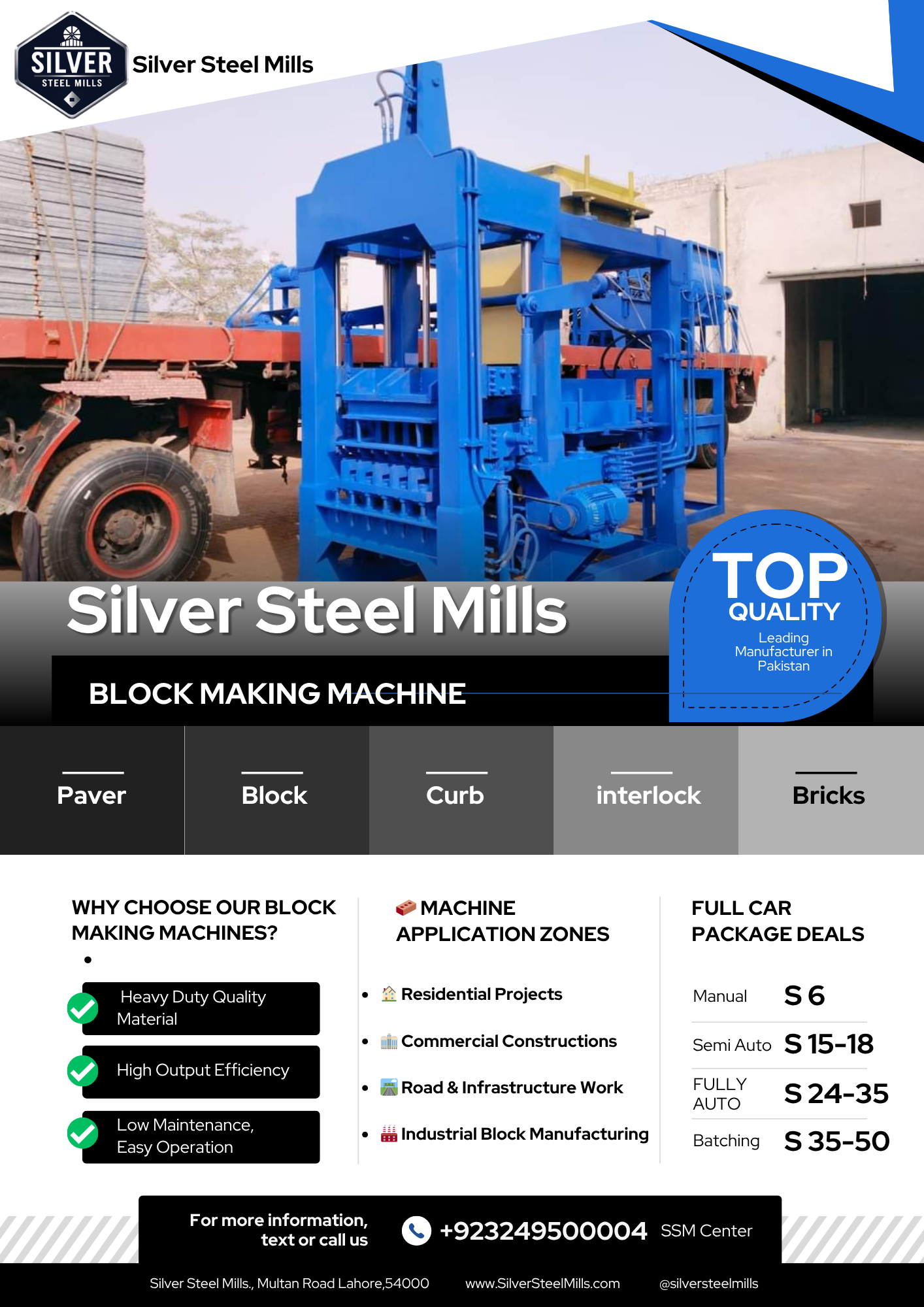

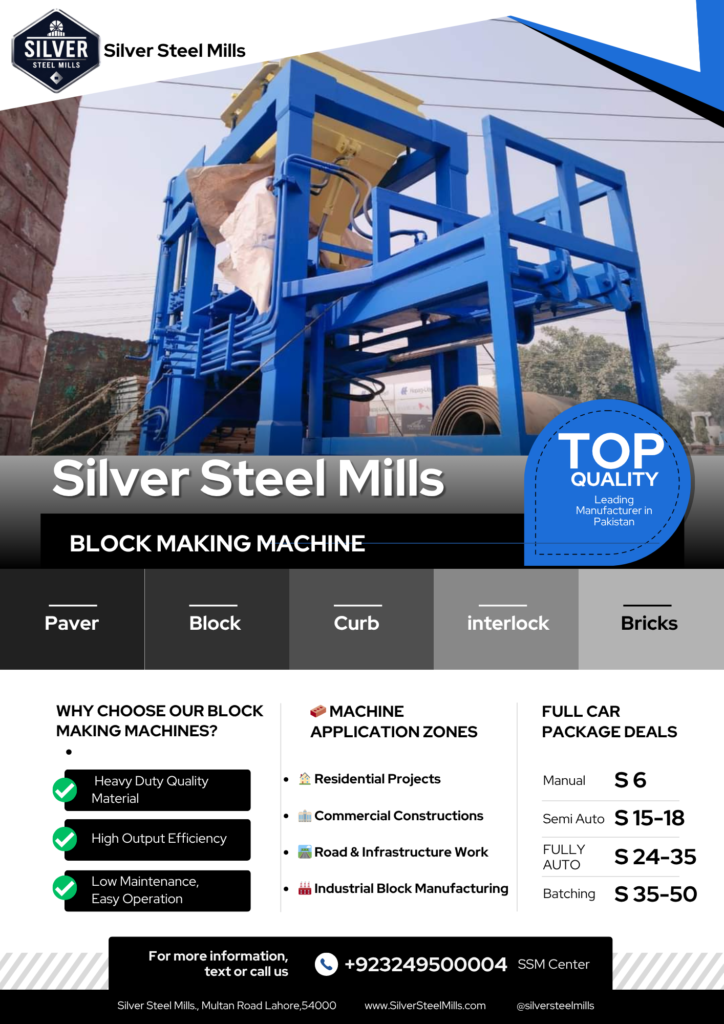

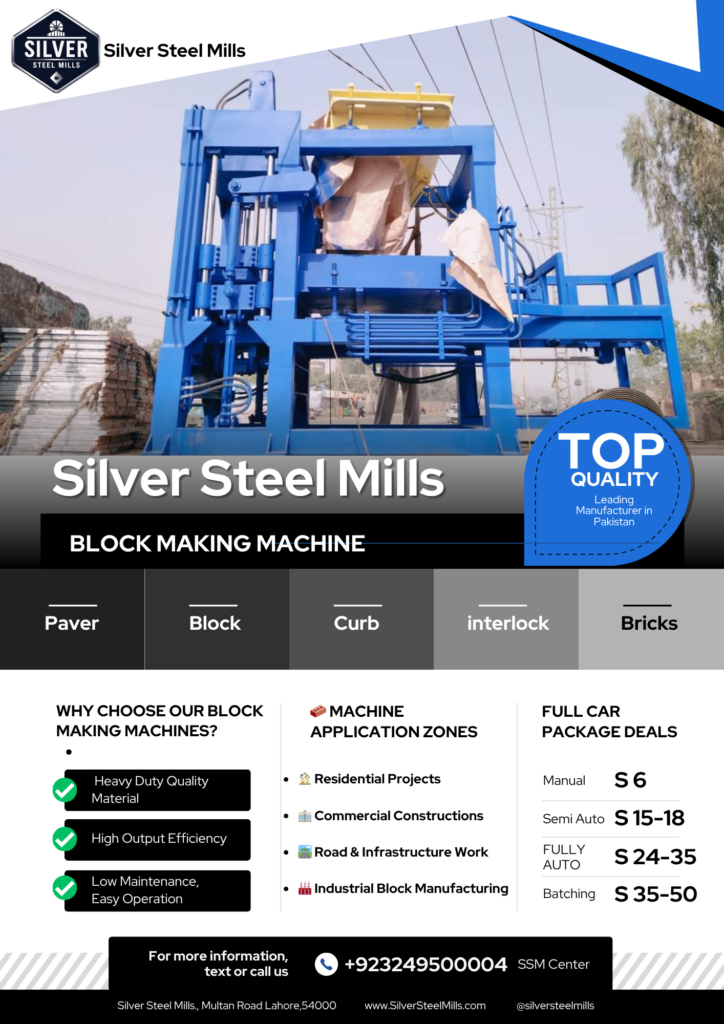

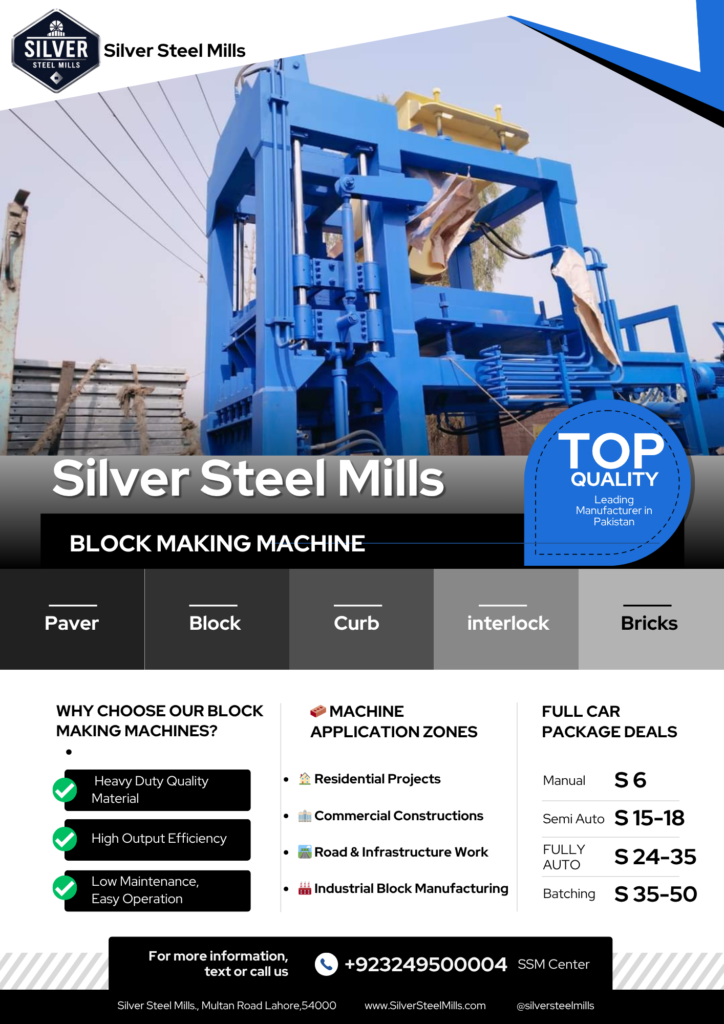

What’s a Paver Block Machine?

A paver block machine is an automatic or semi-automated piece of apparatus used for producing interlocking concrete paver blocks. These blocks are perfect for out of doors flooring on account of their energy, longevity, and talent to face up to various climate circumstances. The machines are available varied fashions, relying on the dimensions of manufacturing, and may produce a wide range of sizes and shapes of pavers.

Options of Paver Block Machines

-

Computerized and Semi-Computerized Choices: Paver block machines in Pakistan are available each computerized and semi-automatic fashions. Computerized machines are perfect for high-volume manufacturing and require minimal human intervention, whereas semi-automatic machines supply flexibility for smaller-scale operations.

-

Excessive Manufacturing Capability: These machines are designed to supply 1000’s of paver blocks per day, relying on their dimension and mannequin. Some machines can produce over 10,000 blocks day by day, making them appropriate for large-scale manufacturing.

-

Sturdiness and Effectivity: Paver block machines are constructed to final, with high-quality supplies comparable to metal and forged iron getting used of their building. They’re designed to deal with steady operations with out compromising on high quality.

-

Number of Molds: Most paver block machines supply interchangeable molds, permitting producers to supply completely different sizes and shapes of blocks, together with sq., rectangular, and interlocking designs.

-

Hydraulic Urgent System: A hydraulic press is used to compress the combination of concrete within the molds, making certain the blocks are of excessive energy and uniform consistency. This function is widespread in most trendy paver block machines.

-

Low Upkeep: These machines are designed for ease of upkeep, with easy operational and cleansing processes. Common upkeep can assist lengthen the machine’s life and guarantee constant efficiency.

Paver Block Machine Specs

The specs of a paver block machine can differ based mostly on the mannequin and producer. Under are the overall specs you possibly can anticipate:

-

Capability: Ranges from 2000 to 10,000 blocks per day relying on the mannequin and manufacturing scale.

-

Molding System: Hydraulic or mechanical.

-

Motor Energy: Usually ranges from 10 HP to 30 HP, relying on the machine’s capability.

-

Vibration System: Electrical or hydraulic vibration system for higher compaction.

-

Compression Stress: 100-300 tons of strain, making certain high-quality blocks.

-

Automation: Full automation in some fashions; semi-automatic machines can be found as properly.

-

Dimensions of Blocks: Can vary from normal 200x100x60 mm to personalised sizes.

-

Electrical Energy Consumption: Varies between 10-30 kW relying on the mannequin.

Paver Block Machine Worth in Pakistan

The value of a paver block machine in Pakistan varies based mostly on components just like the machine’s capability, automation stage, and extra options. Right here’s a basic worth vary:

-

Small-Sized Semi-Computerized Machines: Costs for entry-level machines begin from roughly PKR 500,000 to PKR 1,500,000. These machines are appropriate for smaller-scale manufacturing or as entry-level choices for startups.

-

Medium-Sized Computerized Machines: These machines, with greater manufacturing capacities and superior options, vary from PKR 1,500,000 to PKR 4,500,000.

-

Massive-Scale Absolutely Computerized Machines: For top-production capability, totally computerized machines can value wherever between PKR 4,500,000 to PKR 10,000,000 or extra, relying on the model, capability, and extra functionalities.

Use Instances of Paver Block Machines

-

Highway Building: Paver blocks are generally used for setting up highway surfaces on account of their sturdiness and ease of upkeep.

-

Sidewalks and Pathways: The interlocking nature of paver blocks makes them splendid for pedestrian walkways, including each performance and aesthetic worth.

-

Driveways and Parking Tons: Paver blocks are used for creating driveways and parking tons, providing excessive resistance to heavy masses and put on.

-

Out of doors Landscaping: The number of designs and colours obtainable makes paver blocks splendid for landscaping tasks, together with backyard walkways, patios, and pool surrounds.

-

Industrial Areas: Paver blocks are utilized in warehouses and factories the place heavy equipment operates on account of their skill to face up to heavy masses and fixed use.

Advantages of Paver Block Machines

-

Price-Efficient Manufacturing: Paver block machines permit producers to supply blocks at a low value per unit, considerably rising profitability over time.

-

Environmental Sustainability: Paver blocks are constructed from concrete, and they are often manufactured utilizing native uncooked supplies, decreasing transportation prices and selling eco-friendly building.

-

Sturdiness and Power: The high-strength blocks produced by paver block machines are immune to put on, weathering, and heavy visitors, making certain an extended lifespan.

-

Aesthetic Flexibility: With varied mildew choices obtainable, paver block machines can produce blocks in several shapes, colours, and patterns, enhancing the visible enchantment of outside areas.

-

Low Upkeep and Straightforward Set up: Paver blocks require minimal upkeep and might be simply changed or repaired in case of injury, making them a long-lasting answer.

FAQs about Paver Block Machines

Q1: What’s the distinction between computerized and semi-automatic paver block machines?

-

Computerized machines are totally automated, requiring little guide labor. They provide greater manufacturing charges and are perfect for large-scale operations.

-

Semi-automatic machines require guide intervention for some processes, making them extra appropriate for small to medium-scale manufacturing.

Q2: How do I keep a paver block machine?

Common upkeep contains cleansing the molds, checking the hydraulic programs, inspecting the motors, and lubricating transferring components. Following the producer’s upkeep pointers will make sure the machine runs effectively for years.

Q3: What uncooked supplies are required for making paver blocks?

The first supplies for paver blocks embrace cement, aggregates (comparable to sand and crushed stone), and water. Some producers additionally add pigments for shade and components to reinforce the energy and sturdiness of the blocks.

This autumn: Can a paver block machine be used for making different merchandise?

Sure, paver block machines are versatile and may typically be used for producing different forms of concrete merchandise, comparable to hole blocks, strong blocks, and bricks, by merely altering the molds.

Q5: What’s the manufacturing capability of a typical paver block machine?

A typical machine can produce wherever from 2,000 to 10,000 blocks per day, relying on its automation stage and the kind of block being produced.

Shopping for Information for Paver Block Machines

When buying a paver block machine, there are a number of components to think about to make sure that you get one of the best worth on your funding:

-

Capability Necessities: Select a machine with a manufacturing capability that meets your online business wants. In case you plan on producing massive portions, go for high-capacity machines.

-

Automation Stage: Think about the extent of automation required on your manufacturing facility. Computerized machines are extra environment friendly however costlier, whereas semi-automatic machines supply extra flexibility at a cheaper price.

-

Machine Sturdiness: Search for machines made with high-quality supplies that may stand up to steady use. Reputed manufacturers typically present machines with longer lifespans and higher after-sales help.

-

Worth and Guarantee: Evaluate costs from completely different producers and be sure that you perceive the guarantee phrases, together with any protection for components and labor.

-

Technical Assist and After-Gross sales Service: Make sure the producer supplies ample technical help, set up help, and after-sales companies, as this could considerably influence the longevity of your machine.

-

Spare Elements Availability: Select a producer with available spare components to reduce downtime in case of repairs.

Conclusion

Investing in a paver block machine can considerably enhance your manufacturing capability and open doorways to profitable enterprise alternatives within the building trade. By understanding the specs, options, advantages, and pricing, you may make an knowledgeable resolution that aligns with your online business objectives. Whether or not you’re a small enterprise proprietor or planning to arrange a large-scale operation, there may be a variety of paver block machines obtainable to satisfy your wants in Pakistan.