Cement Hollow Block Making Plant Price in Pakistan

Cement Hollow Block Making Plant Price in Pakistan: A Comprehensive Guide

The demand for durable and cost-effective construction materials in Pakistan has seen a significant rise in recent years, leading to an increased interest in manufacturing cement hollow blocks. These blocks are commonly used in the construction of residential, commercial, and industrial buildings due to their strength, lightweight, thermal insulation properties, and overall cost-effectiveness.

In this article, we will delve into the various aspects that influence the price of a cement hollow block making plant in Pakistan. We will cover topics such as the types of plants available, factors affecting pricing, key components of the plants, financing options, and market outlook.

1. Introduction to Cement Hollow Blocks

Cement hollow blocks are precast concrete blocks that are primarily used in the construction of walls and other structures. These blocks are made from a mixture of cement, sand, water, and aggregate, which is poured into molds and allowed to cure. The hollow nature of these blocks makes them lightweight while maintaining strength and stability, making them an ideal building material in both residential and commercial projects.

Hollow blocks are preferred due to their thermal insulation properties, which help regulate temperature and reduce energy costs. They are also more affordable compared to traditional solid concrete blocks. Due to these advantages, cement hollow blocks are increasingly being used in various parts of Pakistan, particularly in urban areas where rapid construction and cost-effectiveness are essential.

For businesses looking to enter the cement hollow block manufacturing sector, purchasing the right machinery is essential. The cement hollow block making plant is the heart of this industry, and understanding its price and key components is crucial for making an informed investment decision.

2. Types of Cement Hollow Block Making Plants

When considering a cement hollow block making plant, businesses have several options, depending on the scale of operation, automation level, and specific requirements. The following are the main types of plants available in the market:

1. Manual Cement Hollow Block Making Plant

A manual cement hollow block making plant requires labor to mix the raw materials, pour the mixture into molds, and remove the cured blocks. While these plants are inexpensive and ideal for small-scale production, they require a significant amount of human labor and time. Manual plants are best suited for businesses that are just starting out or those that have limited capital investment.

Price Range: PKR 300,000 to PKR 800,000

2. Semi-Automatic Cement Hollow Block Making Plant

A semi-automatic plant is a more advanced option compared to manual plants. These plants have machines for mixing the raw materials, pouring the mixture into molds, and sometimes for curing. However, labor is still required for handling the blocks and for certain processes. Semi-automatic plants are ideal for businesses looking to increase production capacity while keeping operational costs in check.

Price Range: PKR 1 million to PKR 3 million

3. Fully Automatic Cement Hollow Block Making Plant

A fully automatic plant uses advanced technology and machinery to handle the entire process, from mixing raw materials to curing the blocks. These plants require minimal manual labor and are capable of producing large quantities of high-quality cement hollow blocks. Fully automatic plants are ideal for large-scale manufacturers and businesses aiming to produce cement hollow blocks in high volumes with consistent quality.

Price Range: PKR 3 million to PKR 10 million (depending on capacity and features)

3. Factors Influencing Cement Hollow Block Making Plant Price in Pakistan

Several factors play a role in determining the price of cement hollow block making plants. Understanding these factors will help businesses make an informed decision when purchasing machinery.

1. Production Capacity

The production capacity of the plant is one of the most important factors influencing the price. Plants with higher output capacity (i.e., the number of blocks produced per hour or day) are generally more expensive. The capacity is usually measured in terms of blocks produced per shift or per day, and the price of the plant increases with the volume of production.

- Small Capacity Plants (producing 1,000 to 3,000 blocks per day): These are usually more affordable and suitable for small-scale businesses.

- Medium Capacity Plants (producing 3,000 to 10,000 blocks per day): These plants are suitable for medium-sized businesses and come with a balance of automation and manual labor.

- High Capacity Plants (producing 10,000+ blocks per day): High-capacity plants are designed for large-scale production and are usually the most expensive.

2. Level of Automation

The level of automation in a plant has a significant impact on its cost. Manual plants are the least expensive but require a lot of labor and have slower production times. Semi-automatic plants come with more mechanized processes but still require manual input for certain tasks. Fully automatic plants, on the other hand, have high-end automation that reduces the need for manual labor and improves production speed and consistency, but they are also the most expensive.

- Manual Plants: Least expensive but labor-intensive.

- Semi-Automatic Plants: Moderate cost with partial automation.

- Fully Automatic Plants: Highest cost with full automation and increased efficiency.

3. Quality of Materials and Technology

The quality of the materials used to manufacture the plant, as well as the technology it incorporates, will influence the price. Plants with advanced features such as high-pressure hydraulic systems, advanced control panels, and automated curing chambers tend to be more expensive but offer better performance and durability.

- Hydraulic Press Systems: More durable and efficient, resulting in higher costs.

- Automation and Control Panels: More advanced systems improve quality control but add to the cost.

- Curing Systems: Efficient curing systems can speed up production and improve the quality of the blocks.

4. Manufacturer and Brand

The reputation and brand of the manufacturer also play a role in determining the price of the cement hollow block making plant. Renowned brands with established track records in providing reliable machinery may charge more due to their reputation, high-quality materials, and after-sales service. In contrast, lesser-known brands may offer more affordable plants but may come with limited support and warranty.

5. Customization and Additional Features

Some manufacturers offer customization options or additional features such as special molds, advanced mixing technology, and automated packing systems. These additional features can increase the cost of the plant but may provide added value in terms of increased productivity, ease of operation, and product variety.

4. Key Components of a Cement Hollow Block Making Plant

A typical cement hollow block making plant consists of several key components that work together to manufacture high-quality blocks. Understanding these components can help businesses make an informed decision when purchasing machinery.

1. Raw Material Feeding System

The raw material feeding system is used to store and supply the necessary ingredients for block production, including cement, sand, aggregates, and water. This system may include silos, conveyors, and automatic batching units that ensure the correct mixture of raw materials.

2. Mixing Unit

The mixing unit combines the raw materials to form the concrete mixture. This may include a pan mixer or a drum mixer, depending on the type of plant. The quality and consistency of the mix directly affect the final product’s strength and durability.

3. Molding System

The molding system is responsible for shaping the mixture into blocks. It uses molds that are placed in the plant’s machine to form the blocks. In semi-automatic and fully automatic plants, this process is largely automated, which ensures uniformity in block shape and size.

4. Hydraulic Pressing System

Many plants use a hydraulic press to compact the concrete mixture into the molds. The pressure applied by the hydraulic system improves the density and strength of the blocks, ensuring they meet the required standards.

5. Curing System

Curing is an essential part of block manufacturing as it helps the blocks to achieve the desired strength and durability. In fully automatic plants, curing chambers with controlled temperature and humidity levels are often used to speed up the curing process.

6. Control Panel

The control panel is the brain of the plant. In fully automatic plants, the control panel is used to regulate all aspects of production, including mixing ratios, molding cycles, and curing time. It also monitors the operation of the machinery and ensures smooth functioning.

7. Packing and Palletizing System

Once the blocks are cured, they need to be packed and palletized for transportation. Some plants come with automated systems for packing and palletizing, reducing labor costs and improving efficiency.

5. Financing Options for Cement Hollow Block Plants in Pakistan

The high initial cost of a cement hollow block making plant can be a barrier for some businesses. However, there are several financing options available to help entrepreneurs invest in this machinery:

1. Bank Loans

Commercial banks in Pakistan offer loans to businesses for purchasing machinery and equipment. The interest rates and terms vary depending on the bank and the borrower’s financial health.

2. Leasing Options

Some manufacturers offer leasing options, allowing businesses to pay in installments rather than making a lump-sum payment. This can ease the financial burden for businesses with limited capital.

3. Vendor Financing

In some cases, manufacturers of cement hollow block plants provide financing or installment plans, allowing businesses to pay for the machinery over time.

4. Government Schemes

The Pakistani government often provides loans or subsidies to businesses in the manufacturing sector, especially those involved in construction-related industries. These schemes may offer favorable interest rates and repayment terms.

6. Conclusion

The price of a cement hollow block making plant in Pakistan depends on several factors, including production capacity, automation level, quality of materials, and brand. Businesses should carefully evaluate their needs, budget, and long-term goals when selecting a plant.

Manual plants are the most affordable, while fully automatic plants offer higher productivity and efficiency at a higher cost. Financing options are available to ease the initial investment burden, and businesses can benefit from government schemes that support the manufacturing sector.

By investing in the right equipment and understanding the market dynamics, businesses can tap into the growing demand for cement hollow blocks and establish a profitable manufacturing operation in Pakistan.

7. Market Trends and Demand for Cement Hollow Blocks in Pakistan

Understanding the market trends and demand for cement hollow blocks in Pakistan is crucial for businesses planning to invest in a cement hollow block making plant. This section will explore the current market dynamics, key drivers of demand, and the future outlook for the industry.

1. Growing Urbanization and Infrastructure Development

Pakistan has experienced significant urbanization over the past few decades. As the population continues to grow, the demand for housing, commercial buildings, and infrastructure has skyrocketed. This urban expansion has resulted in an increased demand for construction materials, including cement hollow blocks.

The government’s focus on infrastructure development projects, such as highways, bridges, and public buildings, has also contributed to the growing need for durable building materials. Cement hollow blocks, due to their cost-effectiveness and thermal insulation properties, are becoming a preferred choice for both residential and commercial construction projects.

2. Cost-Effectiveness and Sustainability

Cement hollow blocks are considered more cost-effective than traditional solid concrete blocks due to their lighter weight and use of less material. This helps reduce transportation and handling costs, making them a preferred option for contractors and builders. The sustainability factor is also important, as hollow blocks are considered eco-friendly compared to other materials due to the use of industrial by-products in their production.

With the growing awareness of environmental issues, builders and construction companies are increasingly opting for green building materials like cement hollow blocks. This trend is likely to continue, further boosting demand for these blocks.

3. Government Policies and Regulations

The government’s construction policies and regulations can significantly influence the demand for cement hollow blocks. For instance, the Pakistan Housing Authority and private sector developers are incentivizing the use of modern building materials, which includes hollow blocks. Moreover, environmental regulations pushing for energy-efficient and sustainable construction methods are also favoring the adoption of cement hollow blocks.

With the government’s emphasis on affordable housing programs and large-scale construction projects, the cement hollow block market is poised for growth.

4. Growth of Real Estate Sector

The real estate sector in Pakistan is undergoing rapid expansion, especially in major cities like Lahore, Karachi, Islamabad, and Rawalpindi. The increase in high-rise buildings, apartments, and commercial spaces is driving the demand for cost-efficient and durable building materials like cement hollow blocks. Additionally, as residential and commercial developers focus on minimizing costs while maintaining structural integrity, cement hollow blocks have become an increasingly popular choice.

8. Competitive Landscape of Cement Hollow Block Manufacturing in Pakistan

As the demand for cement hollow blocks increases, several local and international manufacturers are stepping into the market. The competitive landscape is evolving, with key players offering various products, technologies, and pricing strategies to attract customers. Let’s look at some important factors influencing the competitive environment.

1. Local Manufacturers

Several well-established local manufacturers in Pakistan produce high-quality cement hollow block making plants. These manufacturers are typically well-versed in local market conditions and can offer customized solutions based on regional requirements. Their products are also priced more competitively due to lower shipping and import taxes.

2. International Manufacturers

International manufacturers also cater to the cement hollow block making plant market in Pakistan, offering advanced technologies and high-quality machinery. These plants are often more automated, which leads to higher productivity and fewer labor requirements. However, the prices of these plants are generally higher due to shipping costs and import duties.

Many international brands have a strong presence in the market, often forming partnerships with local distributors to expand their reach. Businesses investing in these plants are attracted by the promise of long-term durability and after-sales service.

3. Product Differentiation and Quality

Product differentiation plays a significant role in the competition. Some manufacturers offer additional features such as automated block handling systems, customized block designs, or energy-efficient curing systems. Quality is another differentiating factor—companies that focus on providing high-quality plants with excellent durability and minimal maintenance costs tend to attract a larger customer base.

4. Price Sensitivity

In Pakistan, many businesses are price-sensitive, particularly small-scale manufacturers. This has led to competition based on cost-effective solutions, with both local and international manufacturers offering competitive pricing on their plants. As businesses grow and expand, they may shift to more automated plants that offer higher productivity, even if it comes with a higher upfront cost.

5. After-Sales Service and Spare Parts Availability

After-sales service and availability of spare parts are crucial for the smooth operation of cement hollow block making plants. Businesses prefer to invest in plants from manufacturers that offer comprehensive support, including maintenance services, spare parts, and technical assistance. Companies that can provide these services at competitive prices often enjoy a loyal customer base.

9. Maintenance and Operating Costs of Cement Hollow Block Plants

In addition to the initial cost of purchasing a cement hollow block making plant, businesses must also consider the ongoing maintenance and operating costs. Proper maintenance is critical for ensuring the longevity and optimal performance of the plant. Below are some of the key maintenance and operating costs that businesses should be aware of:

1. Labor Costs

Even in semi-automatic or fully automatic plants, some level of labor is required for tasks such as raw material handling, packing, and quality control. Labor costs will vary depending on the scale of production and automation. In general, semi-automatic and fully automatic plants require fewer workers, which helps reduce labor costs.

2. Raw Material Costs

The cost of raw materials—such as cement, sand, aggregates, and water—constitutes a significant portion of the operating expenses. Prices for these materials fluctuate depending on the market demand and supply, so manufacturers must account for potential price increases over time.

3. Electricity and Utility Costs

Cement hollow block making plants require a continuous supply of electricity for machinery operation, mixing, and curing. Depending on the scale of the plant, electricity and utility costs can add up, especially if the plant is running on a 24/7 basis.

4. Equipment Maintenance and Repairs

Regular maintenance of equipment such as mixers, hydraulic presses, and molding systems is essential to prevent breakdowns and ensure consistent product quality. Maintenance costs can include spare parts, lubrication, and occasional repairs. Many manufacturers offer annual maintenance packages to help businesses reduce unexpected costs.

5. Transport and Distribution Costs

Once the cement hollow blocks are manufactured, they must be transported to the construction sites or retailers. The cost of transporting blocks depends on the distance, the quantity of blocks being delivered, and the mode of transport. Efficient logistics management can help minimize these costs.

10. Financing a Cement Hollow Block Making Plant: Key Considerations

When financing a cement hollow block making plant, several considerations need to be taken into account to ensure that the business remains financially viable in the long term. Here are some important points to keep in mind:

1. Loan Term and Interest Rates

If financing through a loan, businesses must carefully assess the loan term and interest rates offered by financial institutions. The longer the loan term, the lower the monthly repayment, but businesses may end up paying more in interest over the life of the loan.

2. Down Payment

Most financial institutions will require a down payment (often 10-20% of the total loan amount) before approving the loan. This down payment can be a barrier for businesses that lack sufficient capital.

3. Cash Flow Management

It is important for businesses to have a clear cash flow management plan when investing in a cement hollow block making plant. The plant’s production capacity and the demand for cement hollow blocks will determine the cash flow. Accurate financial planning and forecasting will ensure that businesses can meet their loan repayments and operational costs while remaining profitable.

4. Government Grants or Subsidies

As part of its efforts to promote industrial growth, the government of Pakistan may offer grants or subsidies to businesses in the manufacturing sector. These schemes can help offset the initial costs of purchasing machinery and ease financial burdens.

11. Conclusion

The cement hollow block making business in Pakistan offers significant opportunities due to the growing demand for cost-effective and durable building materials. Understanding the pricing, features, and components of a cement hollow block making plant is crucial for businesses aiming to enter this sector.

12. Key Manufacturers of Cement Hollow Block Making Plants in Pakistan

Several manufacturers and suppliers in Pakistan specialize in cement hollow block making machines. Understanding the market players and their offerings can help businesses make an informed decision when purchasing machinery. This section will highlight the most prominent manufacturers, their product offerings, and their contribution to the industry.

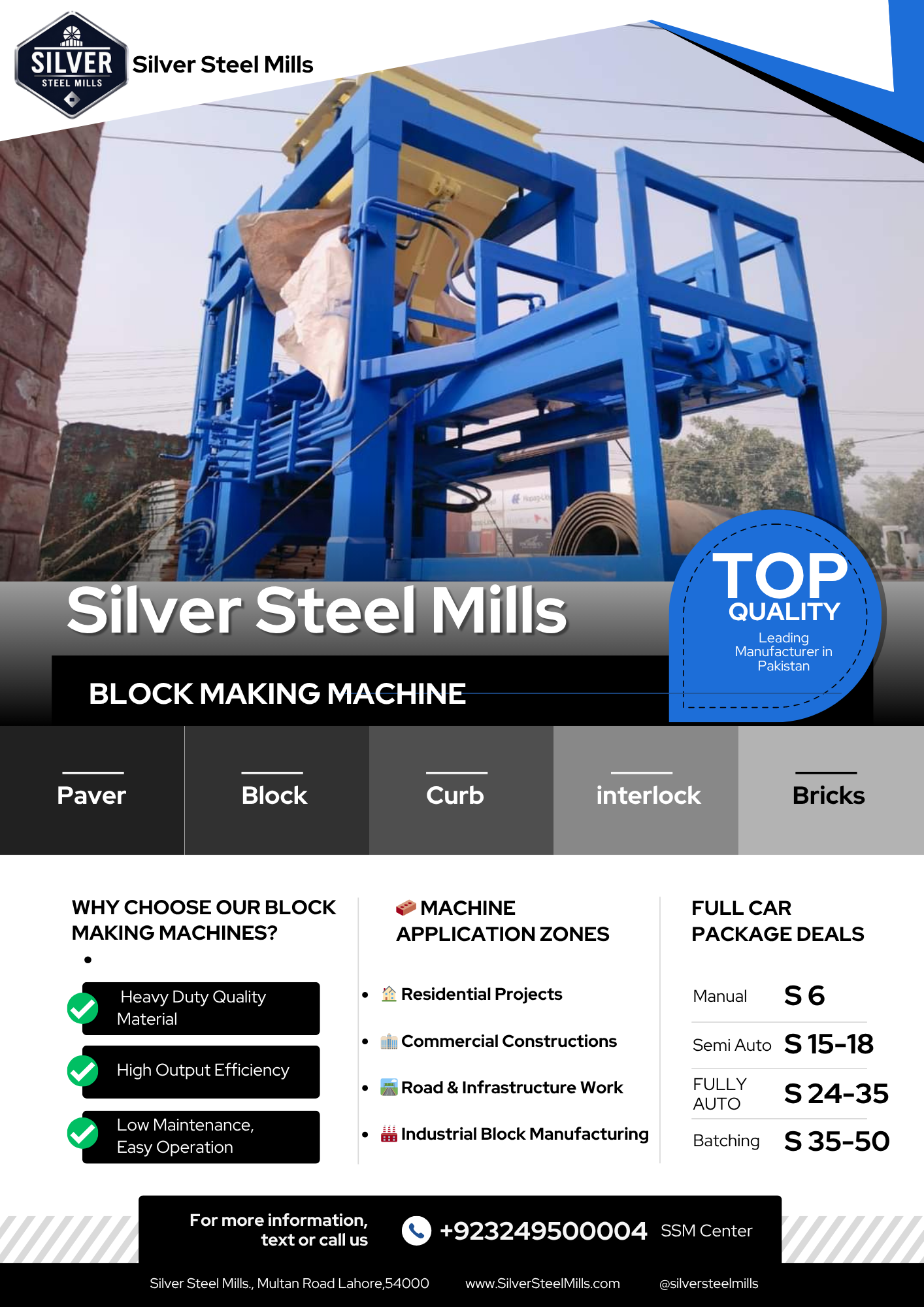

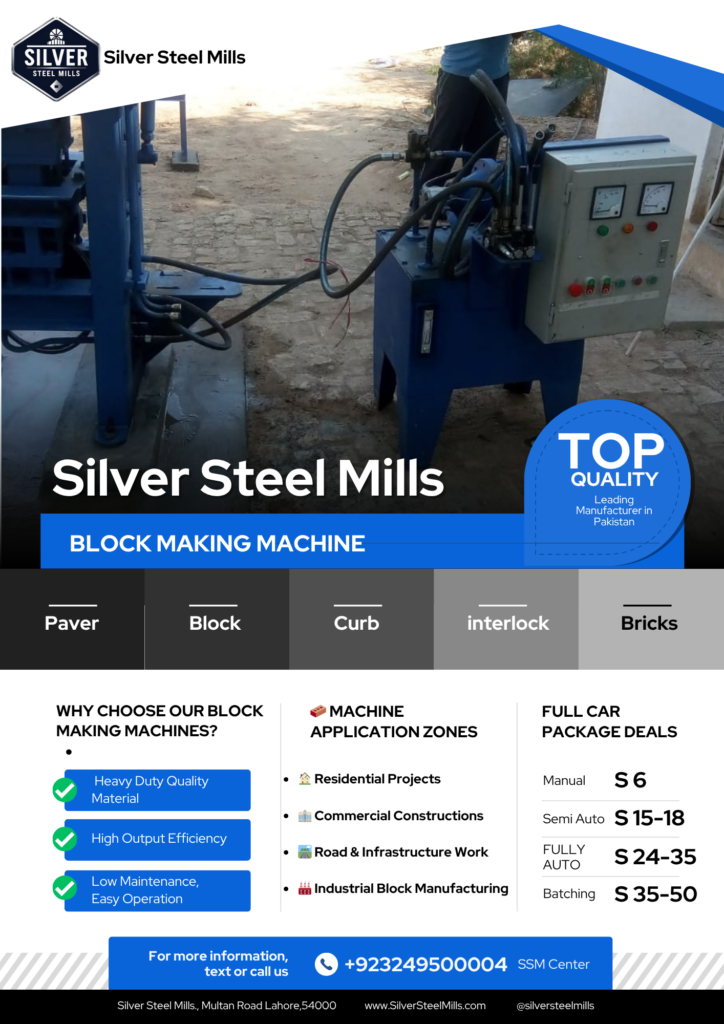

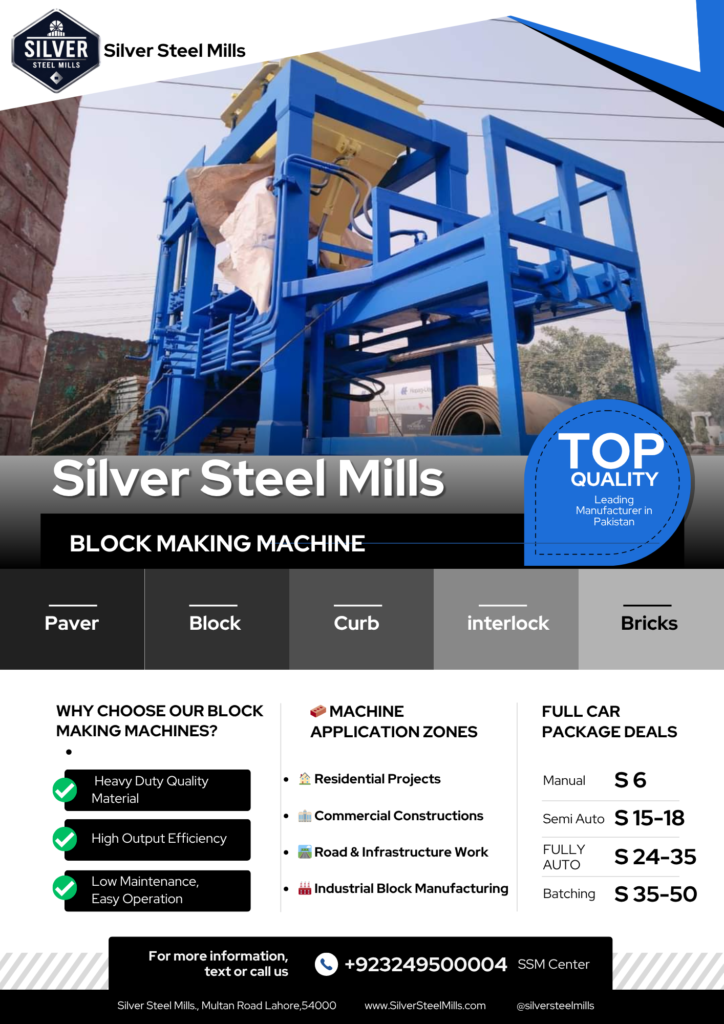

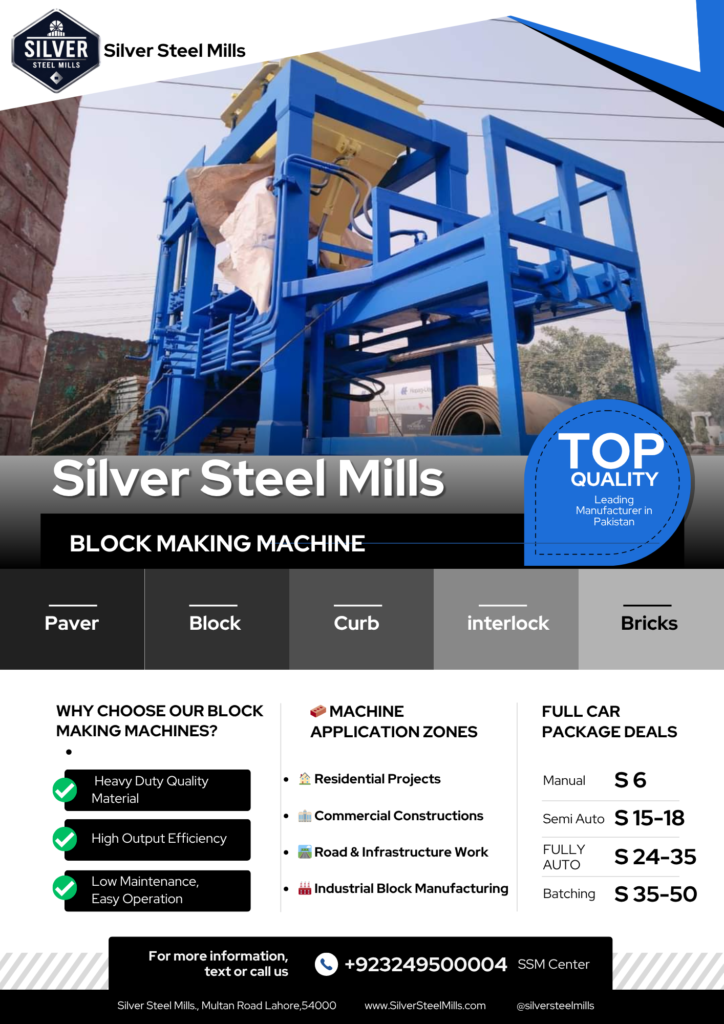

1. Silver Steel Mills: A Leading Manufacturer of Cement Hollow Block Machines

Silver Steel Mills, a prominent name in the manufacturing sector, offers a range of high-quality cement hollow block making machines in Pakistan. With a focus on advanced automation, energy efficiency, and high production capacity, Silver Steel Mills provides plants that cater to both small-scale and large-scale operations.

Key Features of Silver Steel Mills Cement Hollow Block Machines:

- High Production Capacity: Silver Steel Mills’ plants can produce a large number of blocks per day, depending on the machine’s size and automation level.

- Durability and Reliability: The machines are designed with long-term durability in mind, offering consistent performance with minimal downtime.

- Customization Options: Silver Steel Mills offers custom designs based on client needs, including adjustments in block size, shape, and production speed.

- Cost-Effectiveness: With affordable pricing options, Silver Steel Mills makes it easy for businesses to get started with cement hollow block production without high initial investments.

- After-Sales Support: The company provides comprehensive after-sales services, including installation, maintenance, and training.

2. Block Machinery Pakistan

Block Machinery Pakistan is another established manufacturer that specializes in the production of cement hollow block machines. They offer a range of plants that cater to different production scales and automation levels.

Key Features:

- Semi-Automatic and Fully Automatic Options: Depending on the client’s needs, Block Machinery Pakistan provides both semi-automatic and fully automatic machines, offering flexibility in production.

- Competitive Pricing: Their machines are priced competitively, making them a popular choice for businesses looking to start small but scale up operations in the future.

- Technical Support and Training: Block Machinery Pakistan offers training sessions to ensure operators are well-versed in machine operation and maintenance.

3. ZK Corp

ZK Corp is a leading international manufacturer that has expanded its operations to Pakistan. Known for its advanced technology and high-quality machinery, ZK Corp offers cement hollow block making plants equipped with cutting-edge automation.

Key Features:

- Advanced Control Systems: ZK Corp’s machines come with automated control systems that improve production efficiency and reduce human error.

- Energy-Efficient Models: With a focus on sustainability, ZK Corp provides machines that minimize energy consumption while maintaining high output.

- Global Reach: ZK Corp’s international presence allows for easy access to high-quality spare parts and technical support.

13. The Role of Technology in Cement Hollow Block Manufacturing

Technology plays a pivotal role in cement hollow block manufacturing, and its advancements continue to shape the industry. This section will explore the different technological innovations that are transforming cement block production and improving efficiency.

1. Automation in Cement Hollow Block Making Machines

Modern cement hollow block making machines incorporate advanced automation to increase production speed, reduce labor costs, and enhance product consistency. The level of automation can vary, with options ranging from semi-automatic systems to fully automated plants.

Advantages of Automation:

- Increased Productivity: Automated systems can produce more blocks in less time compared to manual labor.

- Precision: Automation ensures precise control over block size, shape, and density, leading to consistent product quality.

- Reduced Labor Costs: Automation minimizes the need for manual labor, resulting in cost savings for businesses.

- Energy Efficiency: Many modern automated machines are designed to be energy-efficient, reducing electricity costs in the long run.

2. Computerized Control Systems

Computerized control systems are now commonly used in cement hollow block making plants. These systems allow operators to monitor and control the entire production process from a centralized interface.

Benefits:

- Real-Time Monitoring: Operators can monitor production metrics such as block quality, production speed, and raw material usage in real-time.

- Improved Efficiency: Automated adjustments can be made to optimize production, ensuring maximum output with minimal waste.

- Data Logging and Analysis: Computerized systems can log production data, allowing businesses to analyze trends and make data-driven decisions to improve productivity.

3. Curing Technology and Quality Control

Curing is a critical step in cement hollow block production, as it affects the blocks’ strength, durability, and overall quality. Modern cement hollow block plants often incorporate advanced curing technology, such as steam curing or autoclave curing systems, to ensure high-quality products.

Benefits of Advanced Curing Technology:

- Faster Curing Time: New curing methods allow for faster setting of blocks, speeding up production cycles.

- Higher Strength: Proper curing enhances the strength and durability of the blocks, making them more suitable for various construction applications.

- Reduced Defects: By controlling the curing process, manufacturers can minimize defects like cracks, which can compromise the structural integrity of the blocks.

4. Energy-Efficient Production

Energy efficiency is a key consideration for modern cement block making plants. Manufacturers are continuously working to develop more energy-efficient machines that help reduce operating costs.

Energy-Saving Innovations:

- Low-Energy Motors: Many plants now use motors that consume less electricity without compromising on performance.

- Heat Recovery Systems: Heat recovery systems can be used to capture and reuse heat energy generated during the curing process, reducing overall energy consumption.

- Solar-Powered Options: Some manufacturers offer solar-powered machines, especially in regions where electricity is costly or unreliable.

14. Environmental Impact of Cement Hollow Block Manufacturing

As concerns about environmental sustainability continue to grow, the cement block manufacturing industry is taking steps to minimize its environmental impact. This section will discuss how cement hollow block manufacturers are incorporating sustainable practices into their operations.

1. Use of Alternative Raw Materials

One of the ways manufacturers are reducing the environmental impact of cement hollow block production is by using alternative raw materials such as fly ash, slag, and recycled aggregates. These materials not only reduce the consumption of virgin resources but also help in reducing carbon emissions associated with cement production.

2. Energy Efficiency and Emission Control

Many cement hollow block plants are incorporating energy-efficient technologies and emission control systems to reduce their carbon footprint. For example, some plants use fuel-efficient kilns and smoke filtration systems to minimize harmful emissions.

3. Waste Reduction and Recycling

Cement hollow block manufacturers are also adopting waste reduction practices, including recycling production waste, such as broken blocks or waste aggregates, into new blocks. This not only reduces material wastage but also contributes to sustainable production processes.

4. Water Conservation

Water is essential for cement block production, and some plants are implementing water recycling systems to minimize water usage and waste. These systems capture and purify water used in the production process, making it available for reuse.

15. Conclusion

The cement hollow block making business in Pakistan is a promising venture for entrepreneurs and manufacturers, given the growing demand for affordable and durable construction materials. With advancements in technology, increasing demand in the construction sector, and various financing options, investing in a cement hollow block making plant is a viable option for many businesses.

By considering key factors such as raw material costs, technology, market demand, and sustainability, businesses can optimize their operations and contribute to the booming construction industry in Pakistan. With careful planning, a high-quality plant, and strategic decision-making, entrepreneurs can build a successful and profitable cement hollow block manufacturing business.