Description

The Foundation of Progress: Unveiling Pakistan’s Premier Concrete Batching Plants by Silver Steel Mills

Introduction: Powering Pakistan’s Construction Boom with Advanced Batching Plants

Pakistan’s vibrant and rapidly expanding construction sector stands as a testament to the nation’s ambitious vision for growth and development. From the sprawling urban landscapes of Lahore and Karachi to the strategic infrastructure projects connecting major cities and the burgeoning housing schemes across the country, the demand for high-quality, consistent, and readily available concrete is unprecedented. At the very heart of this monumental construction activity lies the concrete batching plant – a critical piece of machinery that orchestrates the precise mixing of aggregates, cement, water, and admixtures to produce the lifeblood of modern structures.

The efficiency and reliability of a batching plant in Pakistan directly impact project timelines, cost-effectiveness, and ultimately, the structural integrity of every building, bridge, and road. As the industry evolves, so does the need for advanced solutions that can meet diverse project demands, from the smallest residential developments requiring a mini mobile concrete batching plant to mega infrastructure ventures necessitating a high-capacity ready mix batching plant. This escalating demand has given rise to a competitive market for batching plant for sale in Pakistan, with discerning buyers increasingly seeking not just equipment, but comprehensive solutions that promise durability, precision, and exceptional after-sales support.

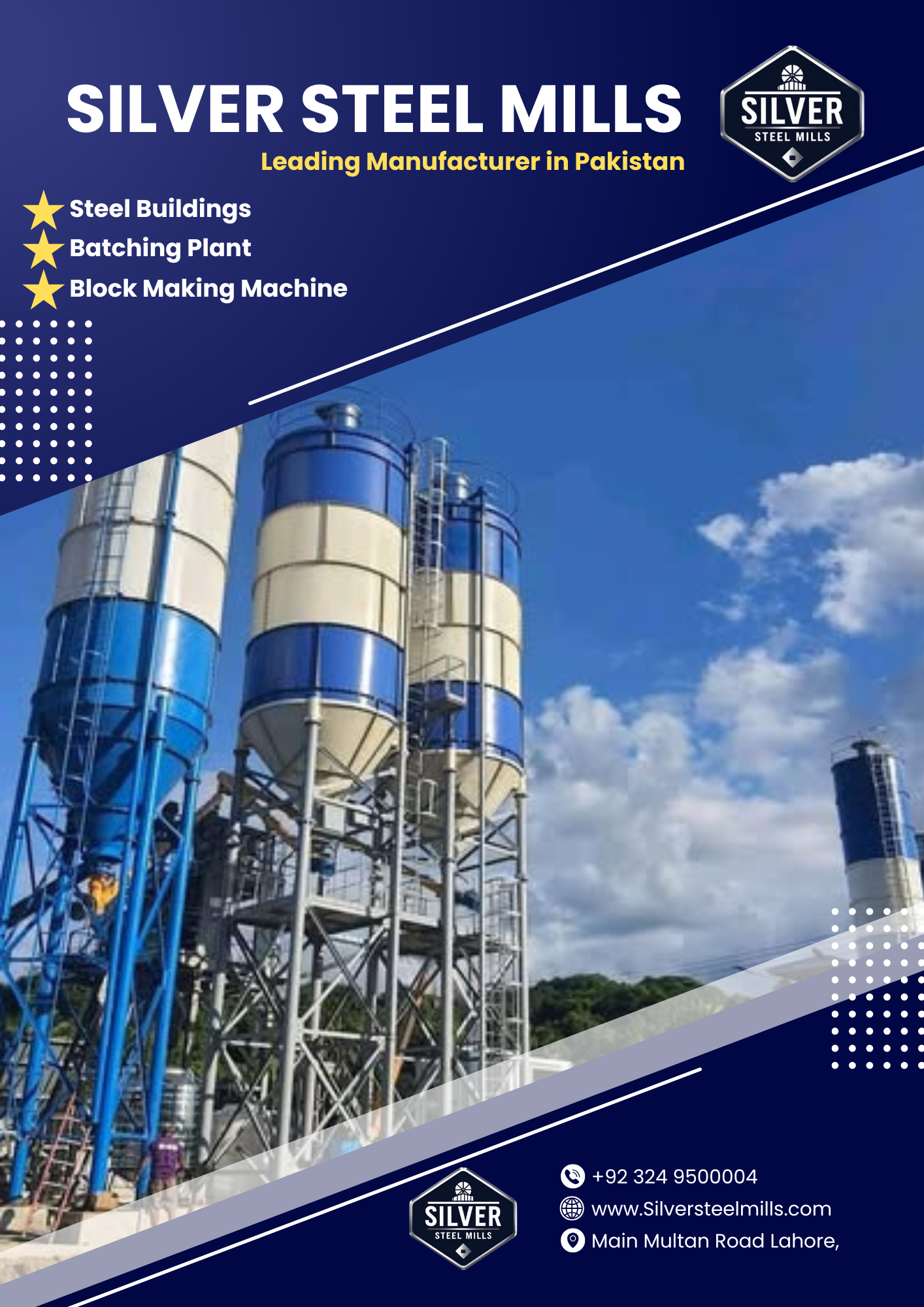

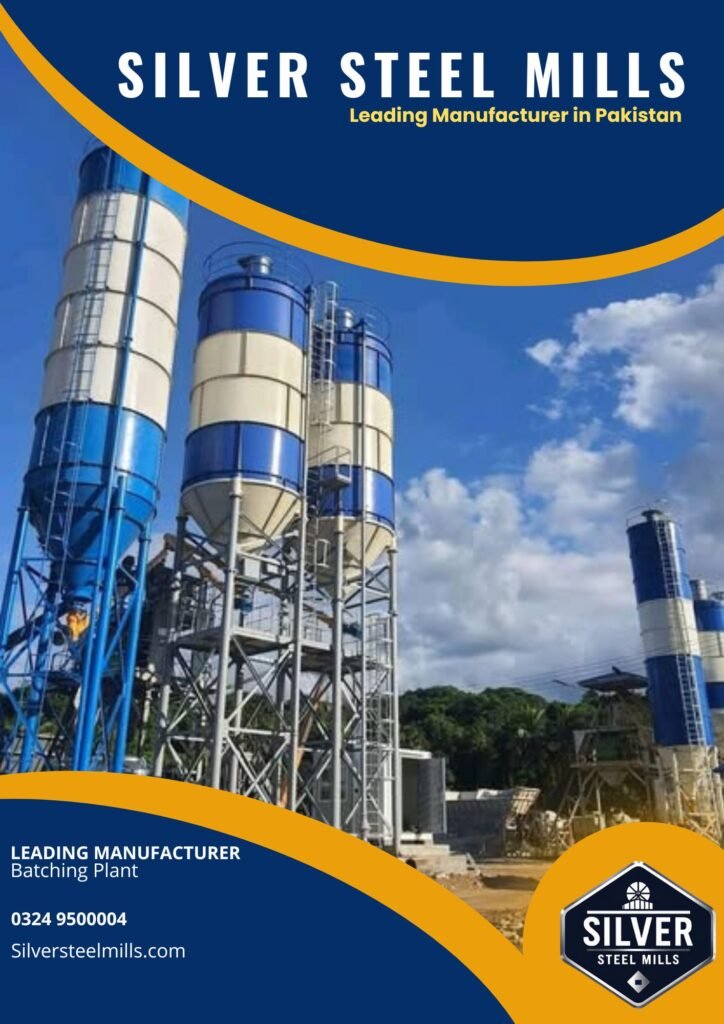

Silver Steel Mills, a name long synonymous with excellence in steel manufacturing and structural engineering across Pakistan, has strategically positioned itself at the forefront of this crucial industry. Leveraging its deep expertise in high-grade steel production and a commitment to cutting-edge engineering, Silver Steel Mills is now recognized as a leading batching plant manufacturer in Pakistan. Our comprehensive range of concrete batching plants is meticulously designed and fabricated to meet the rigorous demands of the local and regional construction markets, offering unparalleled quality, efficiency, and value. This article delves into the indispensable role of modern batching plants, explores the diverse solutions offered by Silver Steel Mills, and illuminates why our commitment to superior materials and client-centric services makes us the premier choice for your concrete production needs.

Why Concrete Batching Plants Are Essential for Pakistan’s Infrastructure Development

The rapid pace of urbanization, industrialization, and infrastructure development in Pakistan necessitates a robust and consistent supply of high-quality concrete. Traditional on-site mixing methods, while once common, are increasingly proving inadequate for the scale, speed, and precision required by modern construction projects. This is where the concrete batching plant steps in as an indispensable asset, transforming the efficiency and quality of concrete production across the nation.

The Limitations of Traditional Concrete Mixing

Historically, concrete was mixed manually or with small, portable mixers directly at the construction site. This approach, however, presents several significant drawbacks:

- Inconsistent Quality: Manual mixing is prone to human error in proportioning ingredients, leading to variations in concrete strength, workability, and durability from batch to batch. This inconsistency can compromise the structural integrity of a project.

- Slow Production Rate: On-site mixing is inherently slow, making it unsuitable for large-scale projects with tight deadlines. Delays in concrete supply can cascade, impacting the entire construction timeline.

- Material Wastage: Inaccurate measurement and spillage during manual mixing often result in significant wastage of expensive raw materials like cement and aggregates.

- High Labor Dependency: Traditional methods require a large labor force for mixing, transporting, and pouring, increasing labor costs and site management complexities.

- Limited Customization: Achieving specific concrete grades or incorporating specialized admixtures for enhanced properties (e.g., rapid hardening, increased durability) is challenging with manual mixing.

- Environmental Impact: On-site mixing can lead to dust pollution, noise, and uncontrolled runoff, impacting the immediate environment.

The Transformative Role of Modern Batching Plants

A modern batching plant in Pakistan addresses these limitations comprehensively, offering a multitude of benefits that are critical for the nation’s ongoing development:

- Unmatched Consistency and Quality Control: The primary advantage of a concrete batching plant is its ability to produce highly consistent concrete batches. Through automated weighing systems (using load cells for aggregates, cement, water, and admixtures) and computer-controlled mixing cycles, every batch adheres precisely to the specified mix design. This ensures uniform strength, workability, and durability, which is fundamental for the safety and longevity of any structure. This precision is vital for projects demanding specific ready mix concrete price in Pakistan based on precise strength grades.

- High Production Capacity and Efficiency: Batching plants are designed for continuous, high-volume production. From a batching plant mini for smaller projects to large ready mix batching plant setups capable of producing hundreds of cubic meters per hour, they significantly accelerate concrete supply. This efficiency is crucial for meeting the demanding schedules of mega-projects, reducing overall construction time, and enabling faster project completion.

- Reduced Material Wastage: Automated and precise batching minimizes material overuse and spillage, leading to substantial cost savings on raw materials. This also contributes to a more sustainable construction process by reducing waste.

- Cost-Effectiveness in the Long Run: While the initial batching plant price in Pakistan might seem like a significant investment, the long-term savings are considerable. Reduced material wastage, lower labor costs (due to automation), faster project completion, and the production of high-quality concrete that minimizes rework and structural issues all contribute to a lower overall project cost and a higher return on investment.

- Versatility and Customization: Modern batching plants offer immense flexibility in producing various concrete grades and types. Operators can easily adjust mix designs to produce high-strength concrete for foundations, lightweight concrete for specific applications, or concrete with specialized admixtures for enhanced properties like waterproofing or rapid setting. This adaptability is essential for diverse construction requirements.

- Enhanced Worksite Safety: Centralized and automated concrete production reduces the need for manual handling of raw materials on-site, minimizing exposure to dust and heavy machinery, thereby improving overall worksite safety.

- Environmental Responsibility: Many modern batching plants incorporate features like dust collection systems, noise reduction measures, and water recycling systems to minimize their environmental footprint, aligning with global sustainable construction practices.

- Reliable Supply for Large Projects: For major infrastructure projects, relying on a dedicated concrete batching plant in Pakistan ensures a steady, uninterrupted supply of concrete, eliminating logistical bottlenecks and dependencies on external suppliers for every batch. This is particularly relevant for projects in bustling urban centers like a batching plant in Pakistan Karachi or a concrete batching plant in Islamabad.

In essence, the concrete batching plant is no longer a luxury but a fundamental necessity for any serious construction endeavor in Pakistan. It represents a shift towards industrialized, quality-controlled, and efficient concrete production, driving the nation’s progress in building a robust and sustainable future.

Types of Batching Plants Available in Pakistan: Tailored Solutions for Every Project

The diverse nature of construction projects in Pakistan, ranging from small-scale residential buildings to massive infrastructure developments, necessitates a variety of concrete batching plant solutions. Manufacturers like Silver Steel Mills understand these varied demands and offer a comprehensive range of plants, each designed to optimize efficiency, quality, and cost-effectiveness for specific applications. These plants can broadly be categorized by their level of automation and mobility.

1. Stationary Concrete Batching Plants

Stationary batching plants are designed for long-term, high-volume concrete production at a fixed location. They are the backbone of ready mix concrete (RMC) operations, supplying concrete to multiple construction sites within a geographical radius.

- Characteristics:

- High Production Capacity: Typically ranging from 60 m³/h to over 200 m³/h, capable of continuous, large-scale output.

- Robust Structure: Built with heavy-duty steel frames, often requiring substantial foundations for stability.

- Advanced Automation: Usually equipped with fully automatic control systems for precise batching and consistent quality.

- Durability: Designed for extended operational life with minimal wear, especially when constructed with high-grade steel.

- Ideal for: Large infrastructure projects (dams, highways, bridges), major commercial and residential developments, and commercial RMC suppliers.

- Keywords Relevance: Often associated with ready mix concrete plant for sale, concrete plant for sale, and discussions around concrete batching plant price in Pakistan for high-capacity, long-term investments.

2. Mobile Concrete Batching Plants

Also known as portable concrete plant or mobile batching plant, these units are engineered for maximum flexibility and rapid deployment. They are mounted on a towable chassis, allowing for easy transportation between different project sites.

- Characteristics:

- Portability: Can be quickly dismantled, transported (often on a single trailer), and reassembled at a new location, minimizing setup time.

- Medium Production Capacity: Typically ranging from 25 m³/h to 100 m³/h, suitable for a wide range of small to medium-sized projects.

- Reduced Foundation Needs: Often require only a hardened ground or minimal concrete slab, significantly cutting down on site preparation costs and time.

- Integrated Design: Many components (mixer, aggregate bins, control cabin) are pre-installed on a single chassis for quick setup.

- Ideal for: Road construction, bridge projects, remote site operations, short-term contracts, and projects where concrete needs are spread across multiple locations.

- Keywords Relevance: Highly relevant to mobile concrete batching plant, portable concrete plant, mobile batching plant for sale, mobile concrete plant for sale, portable concrete batch plant for sale, used mobile batching plant for sale, mobile batching plant price, portable batch plant, mobile concrete mixing plant, mobile ready mix concrete plant, small mobile concrete batch plant, mini mobile batching plant, mobile batch plant concrete, mobile batching, mobile concrete mixing, mobile concrete plant truck, mobile mixing plant, mobile plant concrete, and portable concrete batch plant for rent.

3. Compact Concrete Batching Plants

Compact plants offer a balance between the high capacity of stationary units and the mobility of portable ones. They feature a modular design that allows for relatively easy transportation and quicker setup than traditional stationary plants, without compromising significantly on output.

- Characteristics:

- Modular Design: Components are designed for easy assembly and disassembly.

- Optimized Footprint: Smaller site requirement compared to traditional stationary plants.

- Good Production Capacity: Can offer capacities comparable to medium-sized stationary plants.

- Ideal for: Urban construction sites with limited space, precast concrete production facilities, and projects requiring a balance of capacity and transportability.

4. Categorization by Automation Level

Beyond mobility, batching plants are also classified by their level of automation:

- Manual Batching Plants: Rely heavily on manual labor for weighing and feeding materials. Less precise and slower, but with a lower initial batching plant price in Pakistan. Suitable for very small, infrequent projects.

- Semi-Automatic Batching Plants: Incorporate some automated weighing systems but still require manual intervention for certain operations like material feeding or discharge. Offer a balance between cost and efficiency.

- Fully Automatic Batching Plants: Feature advanced computer-controlled systems that manage the entire batching process, from material feeding and weighing to mixing and discharge, with minimal human intervention. They ensure the highest precision, consistency, and efficiency. This is the preferred choice for modern ready mix concrete production.

Silver Steel Mills’ Commitment to Quality Across All Types

Regardless of the type or level of automation, Silver Steel Mills ensures that every batching plant it manufactures or supplies is built to the highest standards. Our expertise in steel fabrication means that the structural integrity, durability, and operational efficiency of our plants are second to none. We understand that the core strength of a concrete batching plant originates from the quality of its steel components, and our commitment to this fundamental principle sets us apart as a leading batching plant manufacturer in Pakistan.

Silver Steel Mills’ Batching Plant Range: Precision, Power, and Performance

Silver Steel Mills stands as a beacon of engineering excellence in Pakistan, not only as a premier steel producer but also as a leading manufacturer and supplier of high-performance concrete batching plant solutions. Our extensive range is meticulously designed to meet the diverse and demanding requirements of the modern construction industry, ensuring that every project, regardless of its scale or complexity, benefits from superior concrete quality and efficient production.

Our commitment to quality begins with the very foundation of our products: the high-grade steel we utilize. As a vertically integrated entity, our control over the steel manufacturing process ensures that every structural component of our batching plant is forged from materials that meet stringent international standards for strength, durability, and resilience. This inherent quality, combined with precision engineering and state-of-the-art fabrication, positions Silver Steel Mills as the preferred choice for a batching plant for sale in Pakistan.

Our Flagship Offerings: Tailored for Excellence

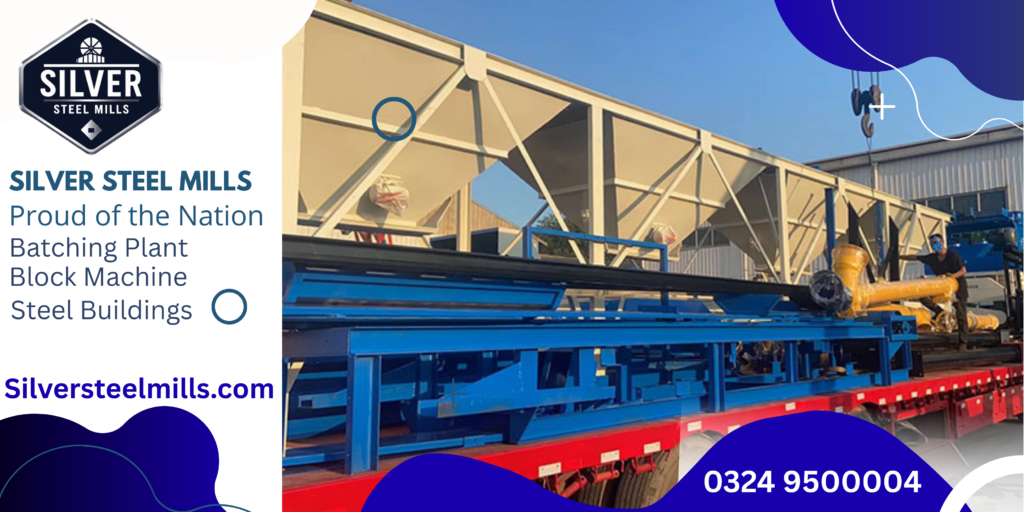

Silver Steel Mills offers a comprehensive portfolio of batching plants, including both stationary and mobile units, designed for various capacities and applications. While we provide a range of models, our commitment to detailing and quality is exemplified through our popular JS series mixers, which form the heart of many of our plants.

Let’s delve into the specifications of a representative model, the JS500 mixer, often integrated into our smaller to medium-capacity plants, demonstrating the meticulous detail and quality that defines our entire range.

JS500 Mixer Batching Plant Specifications (Example)

The JS500 mixer is a twin-shaft compulsory concrete mixer, renowned for its efficient and homogeneous mixing capabilities. When integrated into a complete batching plant, it forms a reliable and productive unit.

Note: This table represents a typical configuration. Silver Steel Mills offers a full range of batching plants with varying capacities and mixer models (e.g., JS750, JS1000, JS1500, and larger), each designed with the same commitment to quality and performance.

Advantages of Buying a Batching Plant from Silver Steel Mills

Choosing Silver Steel Mills for your batching plant in Pakistan is an investment in long-term reliability and operational excellence. Our competitive advantages are rooted in our integrated capabilities and unwavering commitment to client success:

- Unrivaled Steel Quality, In-House: As a leading steel manufacturer, we possess a unique advantage: we control the quality of the steel that forms the very structure of our batching plants from raw material to finished product. This ensures that every beam, plate, and component is made from high-grade, consistent steel, offering superior strength, durability, and resistance to wear and tear. This direct control translates to a batching plant that is built to last, reducing the need for premature replacements or costly repairs.

- Precision Engineering and Design: Our team of highly skilled engineers and designers utilizes cutting-edge software and industry best practices to meticulously design each concrete batching plant. This includes detailed structural analysis, optimization for load-bearing capacities, and ergonomic layouts for efficient operation and maintenance. Our designs prioritize both performance and safety, ensuring compliance with all relevant industry standards.

- State-of-the-Art Fabrication: Our manufacturing facilities are equipped with advanced CNC (Computer Numerical Control) machinery, automated welding systems, and precision cutting tools. This technology ensures that every component of the batching plant is fabricated with millimeter-level accuracy, leading to seamless assembly, optimal performance, and reduced material waste.

- Comprehensive Product Range: Whether you require a compact mobile concrete batching plant for on-site flexibility, a robust stationary plant for high-volume ready mix concrete production, or a specialized solution, Silver Steel Mills offers a diverse portfolio. We cater to various capacities and automation levels, ensuring you find the perfect batching plant for sale that aligns with your project’s specific demands.

- Optimized for Pakistani Conditions: Our batching plants are designed with the unique environmental and operational challenges of Pakistan in mind. From robust construction to withstand diverse climates to efficient designs that account for local aggregate types and power supply variations, our plants are built for optimal performance in the Pakistani context.

- Cost-Effectiveness Through Durability: While our batching plant price in Pakistan reflects premium quality, the long-term cost savings are significant. The superior durability and reliability of our plants mean reduced downtime, lower maintenance costs, and a longer operational lifespan, translating into a higher return on your investment over time.

- Automation for Precision and Efficiency: Our batching plants come equipped with advanced, fully automatic PLC (Programmable Logic Controller) based control systems. These systems ensure precise weighing of all ingredients, optimal mixing cycles, and comprehensive data logging, leading to consistently high-quality concrete and efficient operation with minimal human error.

After-Sales Service and Support: Our Commitment Beyond the Sale

At Silver Steel Mills, our relationship with clients extends far beyond the initial purchase. We understand that a concrete batching plant is a critical asset, and its uninterrupted operation is vital for your project’s success. Our comprehensive after-sales service and support program are designed to ensure maximum uptime and optimal performance throughout the lifespan of your plant.

Our dedicated support team offers:

- Professional Installation and Commissioning: Our experienced technicians provide expert guidance and on-site support for the efficient and safe installation and commissioning of your batching plant. We ensure that the plant is set up correctly, calibrated precisely, and fully operational before handover.

- Operator Training Programs: We provide thorough training for your operational and maintenance staff, equipping them with the knowledge and skills required to operate the batching plant safely, efficiently, and to troubleshoot minor issues. This empowers your team and maximizes plant performance.

- Prompt Technical Support: Our technical support team is readily available to address any operational queries, technical challenges, or performance issues you may encounter. We offer remote assistance and, when necessary, dispatch our expert technicians for on-site support to minimize downtime.

- Readily Available Spare Parts: We maintain a comprehensive inventory of genuine batching plant parts, ensuring quick availability for replacements. This minimizes delays due to part shortages and keeps your plant running smoothly. Our parts are manufactured to the same high standards as the original components, ensuring perfect fit and continued reliability.

- Routine Maintenance and Servicing: We offer scheduled maintenance programs and preventative servicing to ensure your batching plant operates at peak efficiency and to identify potential issues before they escalate. Regular maintenance extends the plant’s lifespan and optimizes its performance.

- Warranty Support: All Silver Steel Mills batching plants come with a comprehensive warranty, providing peace of mind and demonstrating our confidence in the quality and reliability of our products.

Customization Options: Tailoring Your Batching Plant to Your Exact Needs

Understanding that no two construction projects are identical, Silver Steel Mills offers extensive customization options for our concrete batching plant range. Our engineering team works closely with clients to tailor solutions that perfectly align with their specific operational requirements, site conditions, and budget.

Customization options include:

- Capacity Adjustments: While we offer standard capacities, plants can be customized to meet precise hourly output requirements.

- Aggregate Bin Configurations: Options for the number and capacity of aggregate bins to accommodate various types and volumes of aggregates.

- Cement Silo Options: Selection of appropriate mobile concrete silo or stationary silo capacities, including multiple silos for different types of cement or supplementary cementitious materials.

- Feeding Systems: Choice between skip hoist (bucket type) or belt conveyor feeding systems for aggregates, depending on site layout and efficiency needs.

- Mixer Type and Size: Selection of the optimal mixer (e.g., twin-shaft, planetary) and its capacity to ensure desired concrete homogeneity and production rate.

- Automation Level: From semi-automatic to fully automated systems with advanced software features for data management and reporting.

- Admixture Systems: Integration of precise admixture dosing systems for specialized concrete mixes.

- Environmental Features: Addition of dust collection systems, noise reduction enclosures, and water recycling units for enhanced environmental compliance.

- Mobility Features: For mobile concrete batching plant models, options for enhanced portability, quick setup features, and integrated control cabins.

- Specialized Components: Inclusion of specific components like ice plants for hot weather concreting, or heating systems for cold weather, if required.

This commitment to customization ensures that when you acquire a batching plant for sale in Pakistan from Silver Steel Mills, you receive a solution that is not just a machine, but a perfectly integrated system optimized for your success.

Batching Plant Price in Pakistan: Understanding Value Beyond the Initial Cost

When considering a batching plant in Pakistan, the concrete batching plant price in Pakistan is undoubtedly a significant factor in the decision-making process. However, a truly professional assessment goes beyond the initial sticker price to evaluate the total cost of ownership and the long-term value proposition. Silver Steel Mills is committed to offering premium quality at competitive prices, ensuring that your investment yields maximum returns through efficiency, durability, and reliability.

Factors Influencing Batching Plant Price

The batching plant price in Pakistan is influenced by a multitude of factors, each contributing to the overall cost and the plant’s capabilities:

- Production Capacity (m³/h): This is the most significant determinant of price. A larger capacity batching plant (e.g., 100 m³/h vs. 25 m³/h) will naturally have a higher price due to larger components, more powerful motors, and more complex systems.

- Type and Mobility:

- Stationary plants generally have a higher initial cost due to their robust structure and often larger components, but offer higher capacities and longer lifespans for continuous operation.

- Mobile concrete batching plant units, while offering portability, can sometimes have a slightly higher per-unit cost for their integrated design and quick setup features. However, they save significantly on foundation and relocation costs.

- Compact plants offer a middle ground, balancing capacity and transportability.

- Level of Automation:

- Manual or Semi-automatic plants will have a lower batching plant price in Pakistan but require more labor and offer less precision.

- Fully automatic batching plants with advanced PLC control systems, precise weighing, and integrated software come at a higher price point but deliver superior consistency, efficiency, and data management, leading to long-term savings and higher quality concrete.

- Mixer Model and Type: The type and capacity of the concrete mixer (e.g., twin-shaft, planetary) significantly impact the price. High-performance mixers known for homogeneous mixing and durability contribute to a higher cost.

- Aggregate Feeding System: Whether the plant uses a skip hoist (bucket type) or a belt conveyor system for aggregates affects design complexity and cost. Belt conveyors are often preferred for higher capacities and continuous feeding.

- Cement Silo Capacity and Type: The number and capacity of cement silos, including options for a mobile concrete silo, influence the overall price. Larger storage capacities increase cost.

- Brand and Manufacturer Reputation: Reputable manufacturers like Silver Steel Mills, known for their quality, engineering expertise, and reliable after-sales service, may have a higher initial price compared to lesser-known brands. However, this premium is justified by superior durability, performance, and long-term support.

- Inclusion of Optional Features: Add-ons like dust collection systems, heating/cooling systems, admixture pumps, specialized control software, or additional aggregate bins will increase the overall concrete batching plant price in Pakistan.

- Delivery, Installation, and Commissioning: These services, often included in a comprehensive package from leading suppliers, contribute to the total cost but ensure proper setup and immediate operational readiness.

- Market Dynamics: Fluctuations in steel prices, raw material costs, and import duties can also influence the final batching plant price in Pakistan.

Silver Steel Mills: Delivering Premium Quality at Affordable Value

Silver Steel Mills understands the competitive landscape for batching plant for sale in Pakistan. Our pricing strategy is designed to offer exceptional value, combining the highest quality materials and engineering with competitive market rates. We believe that true affordability comes from a plant that is:

- Built to Last: Our use of high-grade steel, produced in-house, ensures unparalleled durability, reducing the need for frequent repairs and replacements, which are often hidden costs in cheaper alternatives. This means your batching plant will deliver consistent performance for many years, maximizing its operational lifespan.

- Highly Efficient: Precision engineering and advanced automation minimize material wastage and optimize energy consumption, leading to lower operational costs over time. This efficiency directly impacts your bottom line, making our plants a more economical choice in the long run.

- Backed by Comprehensive Support: Our robust after-sales service, readily available batching plant parts, and expert technical assistance minimize downtime, preventing costly project delays. This support ensures your investment remains productive and profitable.

While you might find a used batching plant for sale at a lower initial cost, the potential for increased maintenance, reduced efficiency, and shorter lifespan often makes a new, high-quality batching plant from Silver Steel Mills a more financially sound decision in the long term. Our commitment is to provide a concrete batching plant price in Pakistan that reflects genuine value, delivering a superior product that outperforms and outlasts.

Batching Plant for Sale in Pakistan: Your Pathway to Unmatched Concrete Production

The search for a reliable batching plant for sale in Pakistan is a critical step for any construction company, contractor, or ready-mix concrete supplier looking to enhance their operational capabilities and ensure consistent concrete quality. The market offers a diverse range, from compact mini mobile concrete batching plant units for small-scale projects to robust stationary plants for massive infrastructure developments. Navigating this landscape requires a discerning eye for quality, reliability, and comprehensive support.

Where and How to Buy a Batching Plant in Pakistan

The process of acquiring a batching plant in Pakistan typically involves several avenues:

- Direct from Manufacturers (Recommended): Purchasing directly from a reputable manufacturer like Silver Steel Mills ensures you receive a brand-new plant, custom-built to your specifications, with full warranty, comprehensive after-sales support, and access to genuine batching plant parts. This is the most reliable option for long-term investment.

- Authorized Dealers/Distributors: Many international and local manufacturers operate through a network of authorized dealers. These dealers can provide sales, installation, and support services.

- Online Marketplaces: Platforms like batching plant in Pakistan OLX or other industrial equipment marketplaces might list used batching plant for sale options. While these can offer lower initial batching plant price in Pakistan, they come with inherent risks regarding condition, warranty, and long-term support. Careful inspection and professional assessment are crucial for used concrete plants for sale.

- Auctions/Liquidations: Occasionally, plants may be available through auctions, often at competitive prices. However, these sales are typically “as-is, where-is” and require significant expertise to assess the equipment’s condition.

- Rental Options: For short-term projects or to test a plant’s suitability, some suppliers offer a concrete batching plant on rent or mobile batching plant for rent. This can be a cost-effective solution for temporary needs.

Why Silver Steel Mills is the Top Choice for Your Batching Plant Needs

Silver Steel Mills has established itself as the premier choice for a batching plant for sale in Pakistan due to its unparalleled combination of manufacturing excellence, product quality, and client-centric approach. Here’s why we stand out:

- Integrated Manufacturing Advantage: Unlike many suppliers who merely assemble imported components, Silver Steel Mills leverages its core expertise as a leading steel manufacturer. This means the critical structural components of our concrete batching plant are forged from high-grade steel produced in-house, ensuring superior material quality, consistency, and durability from the very foundation. This control over the raw material translates directly into a more robust and reliable final product.

- Engineered for Pakistani Conditions: Our plants are not generic imports. They are meticulously designed and engineered to perform optimally in Pakistan’s diverse climatic conditions, considering factors like ambient temperatures, dust levels, and specific aggregate characteristics prevalent in regions like batching plant in Pakistan Karachi or concrete batching plant in Islamabad.

- Customization for Perfect Fit: We understand that every project is unique. Silver Steel Mills offers extensive customization options, allowing you to tailor the capacity, type (stationary, mobile concrete batching plant, compact), aggregate feeding system, mixer type, and automation level to your precise operational requirements. This ensures you acquire a batching plant that is perfectly optimized for your needs.

- Unwavering Quality Assurance: Our manufacturing processes adhere to stringent international quality standards. Every component undergoes rigorous inspection and testing, from steel fabrication to final assembly and calibration. This commitment to quality ensures that your batching plant delivers consistent, high-quality concrete, minimizing rework and maximizing project efficiency.

- Comprehensive After-Sales Support: Our dedication to your success extends beyond the sale. We provide expert installation, thorough operator training, readily available genuine batching plant parts, and prompt technical support. This comprehensive service minimizes downtime and ensures the long-term productivity of your investment.

- Transparent Pricing and Value: While we offer premium quality, our batching plant price in Pakistan is competitive and transparent. We focus on delivering long-term value through durability, efficiency, and reliable support, ensuring a superior return on your investment compared to cheaper, less reliable alternatives. We help you understand that the true cost is not just the purchase price, but the operational efficiency and longevity.

- Proven Track Record: Silver Steel Mills has a strong reputation in Pakistan’s industrial and construction sectors, built on years of delivering high-quality steel products and engineering solutions. Our expansion into batching plant manufacturing is a natural progression, backed by the same commitment to excellence.

The Silver Steel Mills Sales Process: Your Journey to Efficient Concrete Production

Acquiring a batching plant from Silver Steel Mills is a streamlined and client-focused process designed to ensure your complete satisfaction:

- Initial Consultation & Needs Assessment: Our expert sales and engineering team will engage with you to understand your project requirements, desired concrete output, site conditions, budget, and any specific operational needs. This initial phase is crucial for recommending the most suitable batching plant solution.

- Customized Proposal & Design: Based on the needs assessment, we will prepare a detailed proposal outlining the recommended batching plant model, its specifications, automation level, and any customization options. This will be accompanied by technical drawings and a transparent batching plant price in Pakistan quotation.

- Manufacturing & Quality Control: Upon confirmation, your batching plant will enter our state-of-the-art manufacturing facility. Throughout the fabrication process, rigorous quality control checks are performed at every stage, from steel component production (leveraging Silver Steel Mills’ core expertise) to assembly and pre-shipment testing.

- Delivery & Installation: We manage the efficient and safe transportation of your batching plant components to your designated site. Our experienced technicians will then oversee or perform the professional installation and commissioning, ensuring the plant is set up correctly and calibrated for optimal performance.

- Training & Handover: Before final handover, your operational staff will receive comprehensive training on plant operation, safety procedures, and basic maintenance, empowering them to manage the batching plant effectively.

- Ongoing After-Sales Support: Our commitment continues post-handover with prompt technical support, readily available genuine spare parts, and optional maintenance contracts to ensure the long-term reliability and efficiency of your Silver Steel Mills batching plant.

Whether you are looking for a concrete batching plant for sale to start a new ready mix concrete business, expand an existing operation, or require a mobile concrete batching plant for a specific project, Silver Steel Mills offers a complete, reliable, and value-driven solution.

Frequently Asked Questions (FAQs) about Batching Plants in Pakistan

Here are some commonly asked questions regarding concrete batching plants in Pakistan, providing valuable insights for potential buyers and industry professionals:

Q1: What is a concrete batching plant and why is it essential for construction in Pakistan?

A1: A concrete batching plant is a facility that combines various ingredients (aggregates, cement, water, admixtures) in precise proportions to produce concrete. It’s essential for modern construction in Pakistan because it ensures consistent concrete quality, high production rates, reduces material waste, and is crucial for large-scale infrastructure and building projects that cannot rely on manual mixing.

Q2: What are the main types of batching plants available from Silver Steel Mills?

A2: Silver Steel Mills offers a comprehensive range, including stationary concrete batching plants for high-volume, long-term projects, and mobile concrete batching plants (also known as portable concrete plant) for flexibility and rapid deployment across different sites. We also provide compact and customized solutions.

Q3: How does Silver Steel Mills ensure the quality of its batching plants?

A3: Silver Steel Mills ensures quality through in-house steel manufacturing, providing high-grade steel for all structural components. This is combined with precision engineering, state-of-the-art automated fabrication, rigorous multi-stage quality control, and adherence to international industry standards.

Q4: What factors influence the batching plant price in Pakistan?

A4: The batching plant price in Pakistan is primarily influenced by its production capacity (m³/h), type (stationary vs. mobile batching plant), level of automation (manual, semi-automatic, fully automatic), mixer type, aggregate feeding system, cement silo capacity, and inclusion of optional features. The manufacturer’s reputation and after-sales support also play a role.

Q5: Can I get a mobile concrete batching plant for sale from Silver Steel Mills?

A5: Yes, Silver Steel Mills offers a range of mobile concrete batching plant for sale, designed for easy transportation, quick setup, and efficient on-site concrete production. These are ideal for projects requiring flexibility and reduced logistics costs.

Q6: What kind of after-sales service does Silver Steel Mills provide for its batching plants?

A6: Silver Steel Mills provides comprehensive after-sales support, including professional installation and commissioning, operator training programs, prompt technical support, readily available genuine batching plant parts, and routine maintenance and servicing options to ensure maximum uptime.

Q7: Is it better to buy a new batching plant or a used batching plant for sale?

A7: While a used batching plant for sale might have a lower initial batching plant price in Pakistan, a new plant from Silver Steel Mills offers guaranteed quality, full warranty, higher efficiency, lower long-term maintenance costs, and access to the latest technology and comprehensive after-sales support, making it a more reliable and cost-effective long-term investment.

Q8: What is the typical production capacity of a ready mix batching plant?

A8: A ready mix batching plant (typically a stationary wet mix plant) can have production capacities ranging from 60 m³/h to over 200 m³/h, designed for continuous, high-volume concrete supply to commercial projects.

Q9: Does Silver Steel Mills offer customization for its concrete batching plant?

A9: Yes, Silver Steel Mills offers extensive customization options, including capacity adjustments, aggregate bin configurations, cement silo types, feeding systems, mixer models, automation levels, and specialized environmental features, to perfectly match your project’s unique requirements.

Q10: How does a mobile batching plant differ from a portable concrete batch plant?

A10: These terms are often used interchangeably. A mobile batching plant or portable concrete batch plant refers to a concrete production unit designed for easy transportation and quick setup at different construction sites, offering flexibility and reducing the need for extensive foundations.

Q11: What makes Silver Steel Mills’ steel superior for batching plant manufacturing?

A11: Silver Steel Mills’ steel is superior due to its high tensile strength, consistent quality, and excellent fabrication properties. This ensures that the batching plant’s structural components can withstand heavy loads, resist fatigue, and are highly receptive to anti-corrosion treatments, contributing to the plant’s overall durability and longevity.

Q12: Can I get a concrete batching plant on rent from Silver Steel Mills?

A12: While our primary focus is on manufacturing and sales, for specific project needs, it’s best to contact Silver Steel Mills directly to inquire about potential rental partnerships or referrals to our clients who offer rental services for our plants.

Q13: What is the advantage of a fully automatic concrete batching plant?

A13: A fully automatic concrete batching plant offers the highest precision in weighing and mixing, consistent concrete quality, reduced labor costs, comprehensive data logging, and remote monitoring capabilities, leading to superior efficiency and reliability compared to manual or semi-automatic systems.

Q14: How does Silver Steel Mills contribute to sustainable construction with its batching plants?

A14: By manufacturing durable and efficient batching plants from high-grade, recyclable steel, Silver Steel Mills contributes to sustainable construction. Our plants also support features like precise batching (reducing material waste) and can be equipped with dust collection and water recycling systems, promoting environmentally responsible concrete production.

Q15: Where can I find a batching plant in Pakistan Karachi or concrete batching plant in Islamabad from Silver Steel Mills?

A15: Silver Steel Mills supplies batching plant solutions nationwide. You can contact us directly through our website to discuss your specific requirements, whether your project is in Karachi, Islamabad, Lahore, or any other part of Pakistan. Our sales team will guide you through the process and provide local support.

Conclusion: Partnering with Silver Steel Mills for Unmatched Concrete Production

In Pakistan’s dynamic construction landscape, the demand for high-quality, reliable, and efficient concrete production is paramount. The concrete batching plant stands as the cornerstone of this industry, transforming raw materials into the vital component of every modern structure. Choosing the right batching plant manufacturer in Pakistan is not just a procurement decision; it is a strategic investment in your project’s success, longevity, and profitability.

Silver Steel Mills, with its deep-rooted expertise in steel manufacturing and its unwavering commitment to engineering excellence, has emerged as the leading provider of advanced batching plant solutions in the country. Our unique advantage lies in our vertically integrated approach, ensuring that every plant is built with superior, in-house produced steel, guaranteeing unparalleled durability, precision, and performance.

From the versatility of a mobile concrete batching plant to the robust capacity of a stationary ready mix batching plant, Silver Steel Mills offers a comprehensive range tailored to meet every construction need. Our commitment extends beyond the initial batching plant price in Pakistan, encompassing meticulous design, state-of-the-art fabrication, extensive customization options, and a dedicated after-sales service program that ensures maximum uptime and peace of mind.

By choosing Silver Steel Mills, you are not just acquiring a batching plant for sale in Pakistan; you are partnering with a legacy of quality, reliability, and innovation. We empower your projects with the strength of superior concrete, forged with the excellence that only Silver Steel Mills can provide.

Elevate your construction capabilities today. For the latest prices, detailed specifications, and to discuss your specific batching plant requirements, visit silversteelmills.com or contact our expert team directly.

Building Tomorrow, Today: The Unseen Strength Behind Pakistan’s Leading Batching Plants

In the dynamic landscape of Pakistan’s burgeoning construction industry, the demand for high-quality, efficient, and reliable concrete batching plant solutions is at an all-time high. From mega infrastructure projects in Karachi and Islamabad to residential and commercial developments spanning Lahore, Faisalabad, and beyond, the need for consistent, ready-mix concrete is foundational. As projects grow in scale and complexity, so does the reliance on advanced batching plant technology.

While many companies offer a batching plant for sale in Pakistan, discerning buyers understand that the true value lies not just in the visible components, but in the unseen strength of the materials, the precision of engineering, and the unwavering commitment to quality. This is where manufacturers leveraging the superior steel from entities like Silver Steel Mills stand apart, setting new benchmarks for durability and performance in the realm of concrete batching plant in Pakistan.

The Backbone of Construction: Why a Quality Batching Plant Matters

A concrete batching plant is the heart of any significant construction project. It’s where the raw ingredients – aggregates, cement, water, and admixtures – are meticulously weighed and mixed to produce the precise, uniform concrete required for robust structures. The integrity of every building, bridge, or road depends on the quality of the concrete it’s built with, making the choice of a batching plant paramount.

In Pakistan, the market offers a wide range, from a batching plant mini for smaller projects to high-capacity ready mix batching plant solutions. Companies often search for a concrete batching plant price in Pakistan or even a used batching plant for sale to optimize costs. However, compromising on quality can lead to significant long-term expenses and, more critically, jeopardize structural safety.

The Silver Standard: How Quality Steel Elevates Batching Plant Performance

The core strength and longevity of any concrete mixing plant for sale are intrinsically linked to the quality of steel used in its construction. Components like aggregate hoppers, conveyor frames, mixer drums, cement silos (including a mobile concrete silo), and the main structural chassis all depend heavily on robust, precisely fabricated steel.

This is where a partnership with a renowned steel supplier like Silver Steel Mills becomes a game-changer for batching plant manufacturers in Pakistan. Silver Steel Mills is known for:

- High-Tensile Strength Steel: Batching plants operate under immense stress from heavy loads of aggregates, cement, and the constant vibration of mixing. Steel from Silver Steel Mills provides the necessary tensile strength and yield capacity to withstand these forces without deformation or structural fatigue. This means a batching plant built with their steel will have a longer operational lifespan and require less maintenance.

- Precision Fabrication: The manufacturing of batching plant components requires millimeter-level accuracy for seamless assembly and optimal performance. Silver Steel Mills provides steel that is consistent in quality and dimension, allowing manufacturers to achieve precise cuts, bends, and welds using advanced CNC machinery. This precision reduces material waste and significantly improves the overall quality and efficiency of the batching plant.

- Corrosion Resistance: Concrete environments are inherently corrosive due to moisture and chemical interactions. Steel supplied by Silver Steel Mills, when properly treated and coated, offers superior resistance to rust and corrosion, safeguarding the structural integrity and appearance of the batching plant over years of operation.

- Structural Versatility: From stationary behemoths to a nimble mobile concrete batching plant, the design flexibility offered by high-quality steel is crucial. Silver Steel Mills’ diverse range of steel profiles allows manufacturers to innovate, creating efficient and adaptable designs, including portable concrete plant and mobile batch plant concrete solutions.

When a batching plant manufacturer in Pakistan chooses Silver Steel Mills, they are not just buying steel; they are investing in the foundational quality that enables them to produce durable, reliable, and high-performing concrete batching plant units for the demanding Pakistani market.

Types of Batching Plants: Meeting Every Project’s Need

The modern construction landscape in Pakistan calls for diverse solutions. Reputable manufacturers, backed by strong material supply, offer various types of batching plant solutions:

- Stationary Concrete Batching Plant: These are permanent or semi-permanent installations, ideal for large-scale, long-term projects or for supplying ready mix concrete to various sites within a city (e.g., providing ready mix concrete price in Pakistan for major construction endeavors). They offer high production capacities and consistent output.

- Mobile Concrete Batching Plant: Also known as a portable concrete plant or mobile batching plant, these units are designed for easy transportation and quick setup at different project sites. This versatility makes them perfect for remote locations, short-term projects, or sites with limited space. Companies often look for a mobile batching plant for sale or even a mobile batching plant for rent in Pakistan.

- Compact Concrete Batching Plant: A hybrid offering the advantages of both stationary and mobile plants, providing significant output capacity within a compact, easily transportable footprint.

- Dry Mix Batching Plant: Aggregates and cement are weighed and mixed dry, with water added at the construction site in a transit mixer.

- Wet Mix Batching Plant (Central Mix): All ingredients, including water, are thoroughly mixed at the plant before being discharged into a transit mixer, ensuring highly consistent concrete quality. This is commonly associated with a ready mix concrete plant for sale.

Manufacturers using high-grade steel can confidently build these varied configurations, ensuring each type of plant delivers optimal performance.

Key Factors When Choosing a Batching Plant in Pakistan

Whether you’re looking for a batching plant in Pakistan Karachi or a concrete batching plant in Islamabad, here’s what to consider:

- Manufacturer’s Reputation: Look for a manufacturer with a proven track record of quality and reliability.

- Steel Quality: Inquire about the source and grade of steel used in key structural components. A manufacturer that proudly uses steel from trusted suppliers like Silver Steel Mills indicates a commitment to durability.

- Production Capacity: Match the batching plant‘s theoretical productivity (m³/h) to your project’s concrete demand.

- Mixer Type: Understand the mixer model (e.g., JS Twin-Shaft mixers are known for efficiency) and its output capacity.

- Automation & Control System: Modern plants feature fully automatic control systems for precise batching and minimal human error.

- After-Sales Service & Spares: Availability of spare parts (crucial for long-term operation, especially for a used concrete batch plant for sale) and technical support is vital.

- Price vs. Value: While a batching plant price in Pakistan is important, prioritize long-term value, including operational efficiency, durability, and reduced downtime, over just the initial cost. For instance, an asphalt batching plant price would be different from a concrete one, but the underlying principles of quality apply.

- Portability (if needed): If your projects are spread out, a mobile concrete plant or portable concrete batch plant might be more cost-effective than a stationary one. You might also find options like a truck mounted concrete batching plant or a small mobile concrete batch plant.

Investing in the Future of Construction

The construction sector in Pakistan is on an upward trajectory, with a steady demand for ready mix concrete price in Pakistan and efficient production methods. Owning a high-quality batching plant, particularly one built with superior materials like Silver Steel Mills’ steel, represents a strategic investment. It ensures consistent concrete quality, reduces operational costs, minimizes project delays, and ultimately contributes to the safety and success of construction ventures across the nation.

While searching for a batching plant in Pakistan OLX or other marketplaces might reveal options, for truly reliable, long-lasting performance and the peace of mind that comes with robust engineering, choosing a reputable manufacturer that partners with the best in the steel industry is paramount.

For the unparalleled performance, durability, and a commitment to excellence, choose a batching plant where quality steel is the foundation of every batch. This is how Pakistan continues to build a stronger future, one perfectly mixed batch of concrete at a time.

Introduction: Constructing Pakistan with Precision

Pakistan’s development trade is quickly evolving, with mega infrastructure tasks, city housing developments, and industrial growth accelerating throughout the nation. On this fast-paced panorama, Concrete Batching Vegetation have change into a foundational necessity for constant, high-quality concrete manufacturing. Whether or not it’s a small housing society or a large-scale dam mission, batching vegetation supply velocity, accuracy, and effectivity in concrete mixing.

Silver Metal Mills, a number one title in Pakistan’s industrial tools sector, supplies superior GT mannequin Concrete Batching Vegetation designed for Pakistani circumstances. Identified for his or her engineering precision, affordability, and sturdiness, GT fashions are actually a well-liked selection amongst builders, contractors, and ready-mix concrete suppliers nationwide.

What’s a Concrete Batching Plant?

A Concrete Batching Plant is an industrial facility used to mix varied elements to kind concrete. These embrace:

-

Cement

-

Water

-

Sand

-

Gravel or crushed stone

-

Admixtures

The batching plant precisely weighs and mixes these supplies in particular proportions, guaranteeing constant concrete energy and high quality with each batch. GT batching vegetation from Silver Metal Mills are engineered to ship top-tier efficiency in each stationary and cell codecs, appropriate for small, medium, and large-scale tasks.

Varieties of GT Concrete Batching Vegetation in Pakistan

Silver Metal Mills manufactures a spread of GT fashions tailor-made for numerous mission necessities. Every mannequin is optimized for:

-

Mixing velocity

-

Automation stage

-

Cement/water ratio accuracy

-

Low energy consumption

-

Lengthy-term sturdiness

✅ GT-20 (Mini Batching Plant)

-

Excellent for: Small residential tasks

-

Output Capability: 20 m³/hour

-

Operation: Semi-Automated

-

Energy Requirement: 15–20 KW

-

Space Required: 800 sq ft

-

Worth Vary: PKR 70 to 85 Lakh

✅ GT-30 (Compact Batching Plant)

-

Excellent for: City development

-

Output Capability: 30 m³/hour

-

Operation: Absolutely Automated

-

Energy Requirement: 25 KW

-

Space Required: 1000 sq ft

-

Worth Vary: PKR 90 to 120 Lakh

✅ GT-45 (Normal Plant)

-

Excellent for: Medium to giant websites

-

Output Capability: 45 m³/hour

-

Automation: PLC Managed Full Auto

-

Energy Requirement: 30–40 KW

-

Space Required: 1200 sq ft

-

Worth Vary: PKR 150 to 180 Lakh

✅ GT-60 (Industrial Use)

-

Excellent for: Prepared-mix concrete provide

-

Output Capability: 60 m³/hour

-

Energy: 50 KW

-

Management System: PLY 1000 HMI & PLC with Auto Calibration

-

Worth Vary: PKR 200 to 280 Lakh

Key Options of GT Concrete Batching Vegetation

Right here’s what makes Silver Metal Mills GT fashions stand out:

1. Excessive-Precision Weighing System

Every GT batching plant consists of an automated weighing system for aggregates, cement, water, and components, guaranteeing constant combine high quality.

2. Sturdy Structural Design

GT vegetation are manufactured with heavy-duty metal, making them appropriate for harsh climate and heavy operations in any a part of Pakistan.

3. Good Management Panel

Outfitted with PLC or SCADA methods, GT batching vegetation enable absolutely automated mixing with real-time information monitoring and storage.

4. Quick Set up & Portability

Some GT fashions, particularly GT-20 and GT-30, are modular and might be put in inside 2–4 days with minimal labor and civil work.

5. Low Upkeep

The mechanical and electrical parts are designed for lengthy service life and simple upkeep.

6. Environment friendly Mixers

Excessive-speed twin shaft or planetary mixers are used to make sure thorough and fast mixing of all parts.

Supplies Utilized in GT Batching Vegetation

-

Cement Silos: 50–100 tons with stage indicators

-

Combination Bins: 2–4 compartments

-

Water Tanks: Corrosion-resistant with stage sensors

-

Management Panel: Absolutely enclosed with mud and water safety

-

Mixer Motors: Excessive-efficiency imported motors

Worth Information (2025 Up to date)

| GT Mannequin | Output (m³/hr) | Worth (PKR) |

|---|---|---|

| GT-20 | 20 | 70 –Lakh |

| GT-30 | 30 | 90 – 120 Lakh |

| GT-45 | 45 | 150– 170 Lakh |

| GT-60 | 60 | 190 – 280 Lakh |

Costs differ based mostly on customization, further silos, and automation ranges.

Set up, Guarantee & Help

-

Set up Time: 2 to six days relying on mannequin

-

On-Web site Technician Help: Supplied by Silver Metal Mills

-

Coaching: Included

-

Guarantee: 1 12 months on electrical & mechanical parts

-

After-Gross sales Help: Spare components & service accessible 24/7

Space & Infrastructure Necessities

-

Land Wanted: 800 to 1500 sq ft (relying on mannequin)

-

Basis: RCC basis with anchor bolts

-

Energy Connection: 3-phase industrial line

-

Water Provide: Clear water supply required

-

Storage: Coated space for aggregates & cement

Why Select Silver Metal Mills?

-

15+ years in industrial manufacturing

-

Specialization in concrete, block, and paver plant equipment

-

Nationwide supply and set up

-

Trendy manufacturing facility at silversteelmills.com

-

Trusted by over 500+ contractors in Pakistan

Functions of GT Batching Vegetation

-

Housing Schemes

-

Roads & Bridges

-

Flyovers

-

Dams

-

Airports

-

Industrial Excessive-Rises

-

Authorities Tenders

Enterprise Advantages for Contractors & Buyers

-

Diminished concrete price per m³

-

Management over uncooked supplies and high quality

-

Revenue from ready-mix gross sales

-

Elevated mission velocity and timeline effectivity

-

Lengthy-term asset with sturdy ROI (inside 12-18 months)

Closing Ideas

For those who’re within the development sector or planning to spend money on infrastructure tasks in Pakistan, a GT Concrete Batching Plant from Silver Metal Mills is usually a game-changer. With inexpensive pricing, sturdy construct, and clever automation, GT fashions ship dependable efficiency for years.

For quotes, session, or orders, go to www.silversteelmills.com and discover the newest GT collection as we speak.

batching plant batching plant in pakistan concrete batching plant in pakistan concrete batching plant price in pakistan concrete batching plant for sale in pakistan batching plant in pakistan price ready mix batching plant in pakistan batching plant in pakistan olx batching plant in pakistan karachi ready mix concrete price in pakistan used batching plant for sale mobile concrete batching plant concrete plant for sale mobile batching plant portable concrete plant mobile concrete plant portable concrete batch plant batch plant for sale mobile batching plant for sale mobile concrete batch plant for sale used concrete plants for sale portable batch plant used concrete batch plant for sale portable concrete batch plant for sale mobile concrete plant for sale batching plant mini asphalt batching plant price ready mix concrete plant for sale mobile concrete batching plant price mini mobile concrete batching plant batching plant price in pakistan mobile batching plant price mobile concrete mixing plant concrete mixing plant for sale elkon concrete batching plant mobile ready mix concrete plant portable concrete batch plant for rent batching plant for sale in pakistan concrete portable batch plant mobile concrete silo truck mounted concrete batching plant small mobile concrete batch plant concrete batching plant in islamabad concrete batching plant mobile concrete batching plant on rent concrete plant for sale used mini mobile batching plant mobile batch plant concrete mobile batching mobile batching plant for rent mobile concrete mixing mobile concrete plant truck mobile mixing plant mobile plant concrete