Tuff Tile Plant Price in Pakistan

1. Introduction to Tuff Tile Plants in Pakistan

Tuff Tile plants are a cornerstone of the modern construction industry in Pakistan. These plants manufacture concrete tiles, commonly referred to as Tuff Tiles, which are widely used in various construction projects, including residential, commercial, and industrial buildings. They are especially popular for outdoor applications such as pavements, driveways, and pathways due to their durability, aesthetic appeal, and low maintenance requirements.

The price of a Tuff Tile Plant is a significant consideration for entrepreneurs and businesses looking to enter the tile manufacturing market. Understanding the costs involved in purchasing, installing, and maintaining a tuff tile plant is crucial for determining the potential return on investment (ROI) and overall profitability.

This article explores the pricing structure of Tuff Tile Plants in Pakistan, the factors that affect the price, and the types of plants available in the market. Additionally, we’ll look into the overall market trends, the potential for profitability, and how businesses can choose the best plant to suit their needs.

2. What are Tuff Tiles?

Tuff Tiles, also known as concrete tiles or interlocking tiles, are precast building materials made from a mix of cement, sand, aggregates, and color pigments. The tiles are pressed under high pressure using specialized machines, which give them their strength and durability. Tuff tiles are used for various purposes, including flooring, pavements, and external landscaping, where durability and aesthetic value are important.

In Pakistan, Tuff Tile manufacturing has become a popular business due to the growing demand for affordable and durable flooring and paving solutions in the construction industry. Tuff tiles are easy to install, require minimal maintenance, and are available in a variety of designs, making them a preferred choice in urban and rural development projects.

3. Types of Tuff Tile Plants

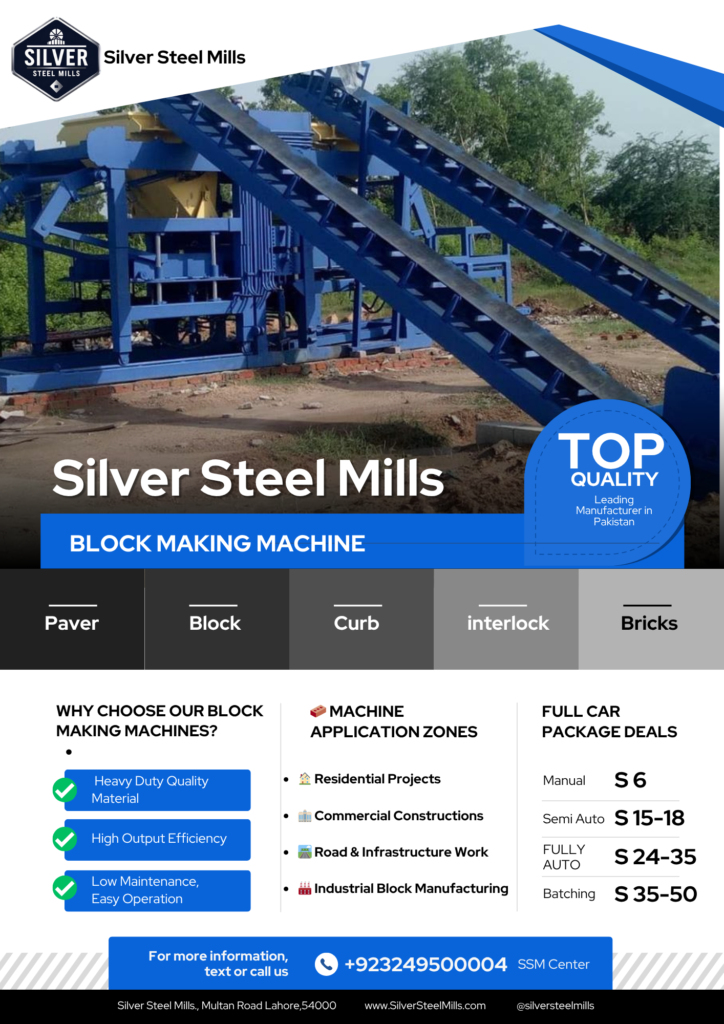

The type of tuff tile plant a business chooses depends on several factors, including production capacity, automation level, space, and budget. Broadly speaking, Tuff Tile Plants can be categorized into semi-automatic, fully automatic, and manual machines.

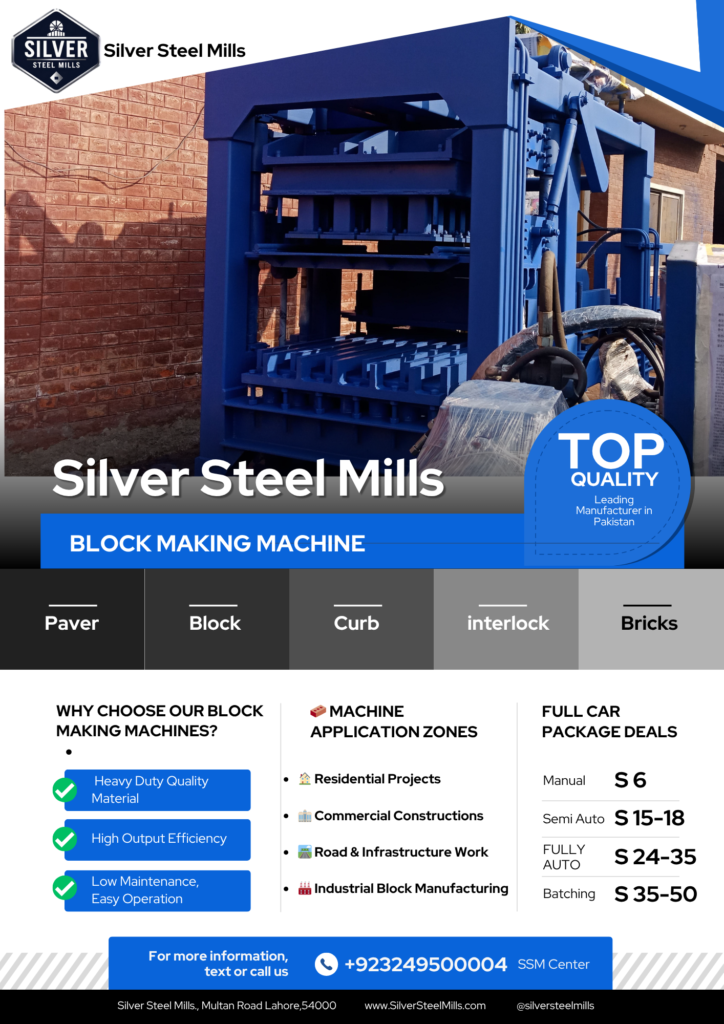

1. Manual Tuff Tile Plants

Manual plants are typically more affordable but require more labor to operate. These plants are suitable for small-scale businesses that can’t afford high investment costs. Production capacity is generally lower, and the process relies on manual labor for tasks like mixing, pressing, and curing.

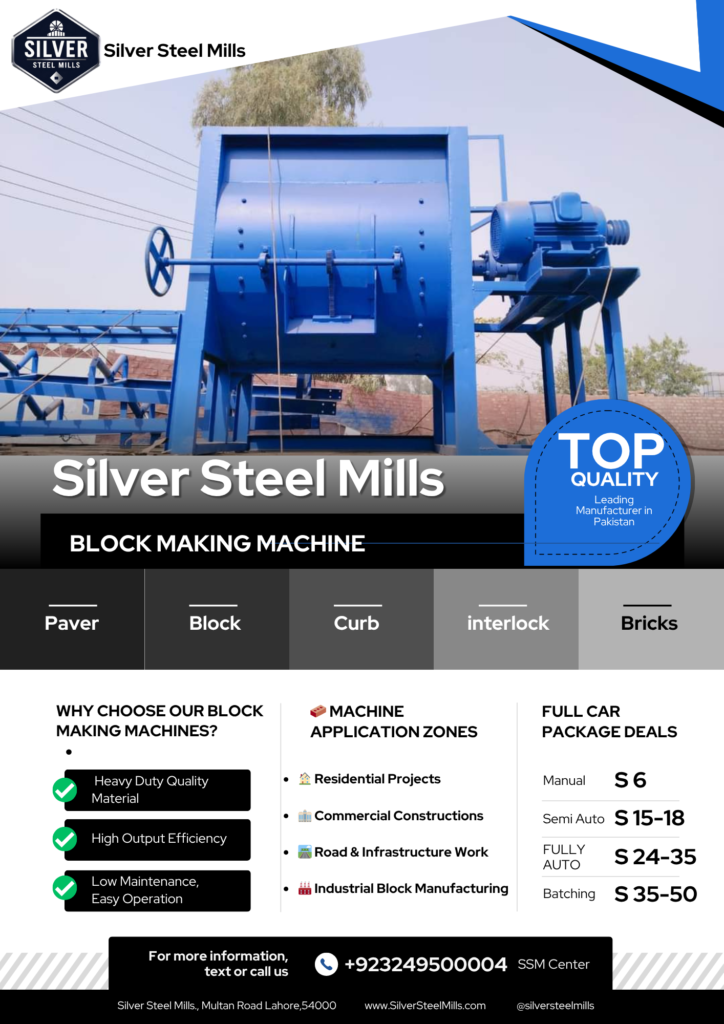

2. Semi-Automatic Tuff Tile Plants

Semi-automatic plants offer a balance between affordability and automation. They reduce the need for manual labor, increasing efficiency and production speed while maintaining a reasonable cost. Semi-automatic plants are ideal for medium-sized businesses looking to expand their capacity without making a huge investment.

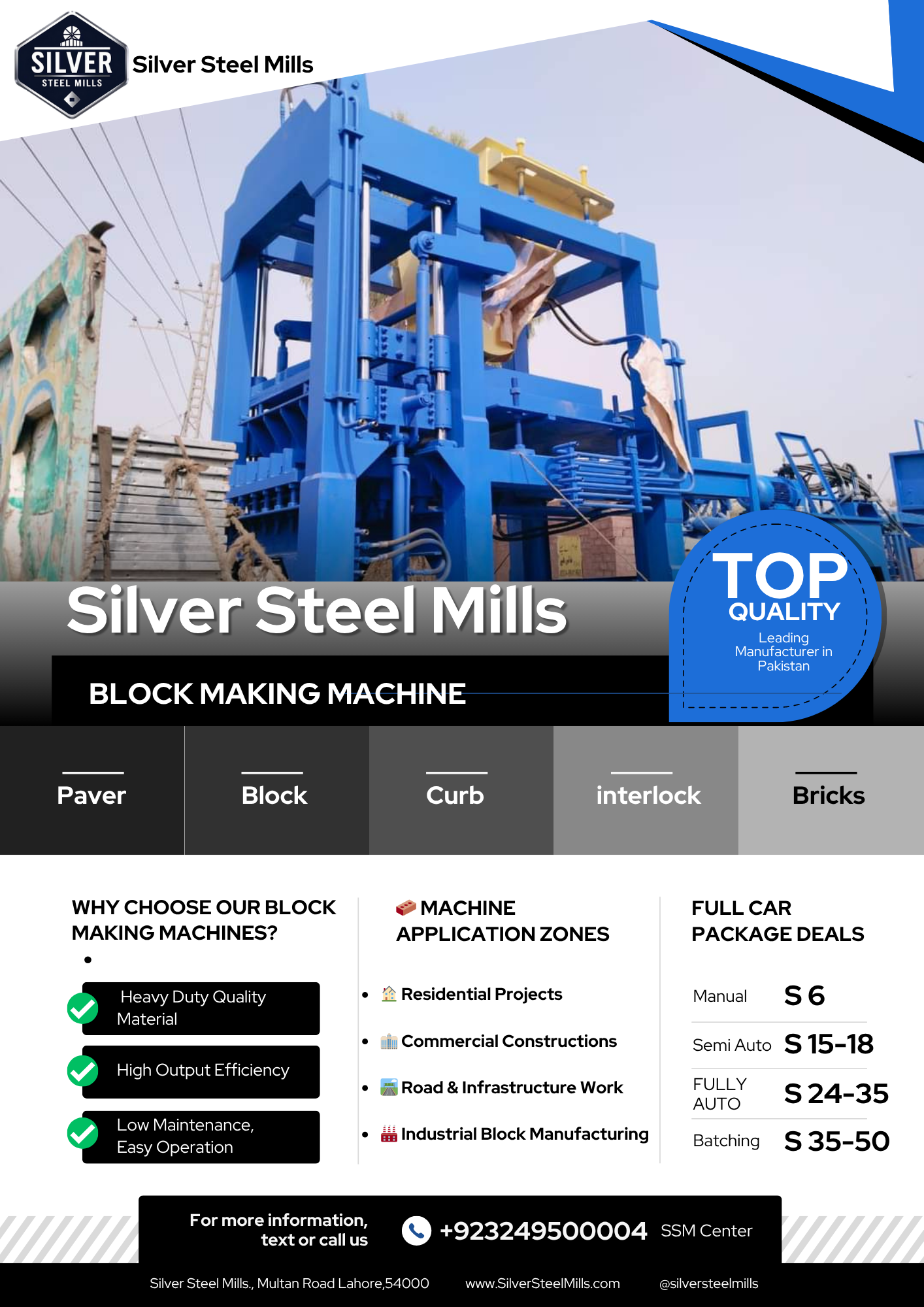

3. Fully Automatic Tuff Tile Plants

Fully automatic plants are the most advanced and efficient type of tuff tile plant. They are capable of producing large quantities of tuff tiles with minimal labor input. These plants are typically more expensive due to the advanced technology and automation systems used. However, they offer the highest production capacity and the best quality consistency, making them ideal for large-scale operations.

4. Factors Influencing Tuff Tile Plant Prices in Pakistan

Several factors influence the cost of tuff tile plants in Pakistan. These include:

1. Plant Capacity

The production capacity of a tuff tile plant plays a major role in determining its price. Plants with a higher output capacity will naturally cost more due to the additional machinery and technology required to handle larger volumes of production. For instance, a plant capable of producing 10,000 tiles per day will cost significantly more than one producing 1,000 tiles per day.

2. Type of Plant (Manual, Semi-Automatic, or Fully Automatic)

As previously mentioned, the level of automation and the type of machine you choose will impact the price. Manual plants are the least expensive, while fully automatic plants are the most costly.

3. Quality of Materials

The quality of the raw materials used in the manufacturing of tuff tiles (cement, sand, aggregates, and pigments) directly impacts the price of the plant. Higher-quality materials will increase the cost of production and, in turn, may require more advanced machinery to handle them.

4. Technology and Features

More advanced plants come with better technology and additional features like:

- Energy-efficient systems: Reducing operational costs over time.

- Advanced mixing and pressing technology: To ensure better quality control and uniformity of tiles.

- Automatic curing systems: To streamline the curing process and increase production speed.

These features will increase the upfront cost of the plant but can improve long-term profitability by increasing efficiency and reducing production time.

5. Brand and Manufacturer

Different manufacturers offer varying prices based on their reputation, quality of machinery, and after-sales services. Renowned brands with a strong service network may charge higher prices, but the value they provide in terms of reliability, after-sales support, and warranty can justify the cost.

6. Location

The price of importing the plant to Pakistan, transportation costs, and the installation process can also impact the overall cost. Plants manufactured within Pakistan may be more affordable due to lower shipping and import duties.

5. Price Range for Tuff Tile Plants in Pakistan

The price range for Tuff Tile Plants in Pakistan varies greatly depending on the factors outlined above. Below is a general breakdown:

- Manual Tuff Tile Plants: The price for manual plants can range from PKR 500,000 to PKR 1.5 million, depending on the production capacity and specific features of the machine.

- Semi-Automatic Tuff Tile Plants: Semi-automatic plants typically range from PKR 1.5 million to PKR 4 million, based on factors such as capacity, automation level, and technology.

- Fully Automatic Tuff Tile Plants: These plants can range from PKR 4 million to PKR 10 million or more, depending on their output capacity, automation, and additional features.

6. Financing Options for Tuff Tile Plants

Investing in a Tuff Tile plant can require significant capital, and not all businesses have the resources to make such a large upfront investment. However, there are several financing options available for purchasing a tuff tile plant in Pakistan:

1. Bank Loans

Banks and financial institutions in Pakistan offer business loans for machinery purchases. The interest rates and repayment terms depend on the bank and the applicant’s financial situation.

2. Leasing

Leasing is another option for businesses that want to avoid large upfront payments. In this case, the business rents the plant and pays in installments.

3. Vendor Financing

Some manufacturers or suppliers of tuff tile plants offer financing options, allowing businesses to pay for the equipment in installments. This can be a good option for businesses looking for flexible terms.

4. Government Programs

The government of Pakistan often has programs and schemes that offer low-interest loans or subsidies to businesses in the manufacturing sector, including the construction materials industry.

7. Operating Costs and Profitability of Tuff Tile Plants in Pakistan

When considering investing in a Tuff Tile Plant in Pakistan, it’s important to not only evaluate the initial price of the plant but also the ongoing operating costs and the potential for profitability. A solid understanding of these factors will help you make informed decisions about your investment and financial planning.

7.1. Operating Costs of a Tuff Tile Plant

Operating costs refer to the expenses incurred for running the plant on a day-to-day basis. These costs are directly related to the production of tuff tiles and can significantly impact profitability. The main operating costs include:

1. Raw Materials

The primary raw materials required for tuff tile production are:

- Cement: The base material used to create the concrete for the tiles.

- Sand: Used as an aggregate to give the concrete a strong foundation.

- Crushed Stone or Gravel: Adds strength and durability to the concrete mixture.

- Pigments: Used to color the tiles and make them aesthetically pleasing.

The prices of raw materials can fluctuate due to factors such as supply and demand, transportation costs, and seasonal changes. On average, raw materials can account for around 40-50% of the total production cost. Bulk purchasing or establishing direct relationships with suppliers can help reduce these costs.

2. Labor Costs

Labor costs depend on the scale of your plant and its level of automation. In manual and semi-automatic plants, labor costs can be higher since manual handling of materials, pressing, and curing is required. In fully automated plants, the need for labor is reduced, which can lower labor costs, although there may still be expenses for technicians, operators, and maintenance staff.

Labor costs can vary depending on location and skill level. However, for a standard tuff tile production facility in Pakistan, monthly labor expenses might range from PKR 150,000 to PKR 400,000 depending on the size of the operation.

3. Utilities (Electricity, Water, Fuel)

Utilities are essential for running any manufacturing plant. The electricity required to power the machinery, water for curing, and fuel for transportation and maintenance vehicles are key components of operating costs. Tuff tile plants often require high electricity consumption for automated equipment, mixers, and other machinery.

In Pakistan, the cost of utilities can vary widely depending on your location, but on average, monthly electricity bills for a medium-sized plant may range between PKR 50,000 and PKR 150,000.

4. Maintenance and Repairs

Regular maintenance is necessary to keep your machinery in good working condition and ensure the smooth operation of the plant. Maintenance costs typically include:

- Routine maintenance of equipment

- Repair costs for machinery breakdowns

- Replacement of worn-out parts

For a fully automatic plant, maintenance costs can range between PKR 100,000 to PKR 300,000 annually, while semi-automatic and manual plants may have slightly lower costs.

5. Transportation Costs

Transporting raw materials to the plant and finished products to distributors or customers involves transportation costs. Depending on the distance from suppliers, raw material costs can vary, and transportation might make up 5-10% of total production costs.

7.2. Profitability of Tuff Tile Plants in Pakistan

Profitability is the ultimate goal for any business, and understanding the factors that influence profit in the tuff tile manufacturing industry is essential.

1. Production Capacity

The higher the production capacity of your tuff tile plant, the more tiles you can manufacture and sell, directly affecting profitability. Larger-scale plants with higher output capacities can often produce tiles at a lower per-unit cost, improving margins.

For example, a fully automated plant producing 10,000 tiles per day at an average price of PKR 50 per tile would generate daily revenue of PKR 500,000. With monthly sales reaching PKR 15 million, the profit margins can be significant, especially when operating costs remain manageable.

2. Tile Pricing

The price at which you sell your tuff tiles is a critical factor in determining profitability. The price can vary depending on:

- Quality: High-quality tiles with more intricate designs and better finishes can be sold at a premium.

- Design: Custom or decorative designs can attract higher prices.

- Market Demand: Prices fluctuate with market conditions and regional demand for construction materials.

The average price of a standard tuff tile in Pakistan typically ranges between PKR 40 to PKR 100 per square foot, depending on quality and design. Higher-end tiles can fetch even more, particularly if they are used in luxury or commercial projects.

3. Break-Even Point

The break-even point is the stage at which your plant covers all its operating expenses and starts making a profit. For a small to medium-sized tuff tile plant, the break-even point could typically be reached within 6 to 12 months, depending on factors such as plant capacity, raw material costs, labor expenses, and product pricing.

4. Profit Margins

Profit margins in the tuff tile manufacturing business can vary based on the size and efficiency of your operations. On average, gross profit margins range from 30-50% for tuff tile manufacturers. However, the net profit margin, which accounts for all operating expenses, taxes, and overheads, may fall between 15-30% for an established business.

For example, a plant producing 100,000 tiles per month and generating PKR 5 million in revenue could have operational costs of around PKR 3 million, leaving a net profit of PKR 1-1.5 million monthly, depending on the efficiency of operations.

5. Market Trends and Demand

Market conditions play a huge role in the profitability of the tuff tile business. The growing demand for sustainable construction materials, affordable housing projects, and landscaping solutions in Pakistan has created a steady market for tuff tiles. Additionally, the government’s focus on urban development and infrastructure projects can create more demand for tuff tiles.

As cities expand and the construction industry grows, the demand for paving and flooring materials like tuff tiles is likely to increase, providing long-term profitability for established businesses.

8. Market Outlook for Tuff Tile Plant Business in Pakistan

The tuff tile manufacturing business in Pakistan has immense potential due to the growing demand for durable and affordable construction materials. As the economy improves and the urban population increases, the need for high-quality, cost-effective paving and flooring solutions is expected to rise.

1. Opportunities in Government and Infrastructure Projects

The government of Pakistan is investing heavily in infrastructure development—roads, highways, residential complexes, and industrial parks—which is a major opportunity for tuff tile manufacturers. Engaging with government contractors can provide consistent orders for your plant and help you establish a stable market base.

2. Commercial and Residential Projects

Both residential developers and commercial construction companies require tuff tiles for exterior walkways, driveways, and public spaces. These sectors offer lucrative long-term contracts for tuff tile manufacturers, especially if you can maintain quality standards and meet delivery deadlines.

3. Export Potential

Another growing opportunity for tuff tile manufacturers in Pakistan is exporting their products to neighboring countries. Afghanistan, Middle Eastern nations, and even some African countries have seen an increase in demand for construction materials, and tuff tiles could represent a strong export product due to their cost-effectiveness and durability.

9. Conclusion

The Tuff Tile Plant Business in Pakistan presents a significant opportunity for entrepreneurs looking to enter the construction materials industry. With an increasing demand for durable, aesthetically pleasing, and cost-effective tiles in the construction sector, tuff tile plants offer the potential for high profitability.

By understanding the costs, pricing strategies, and market demand, businesses can create a sustainable business model and achieve a strong return on investment. Additionally, the proper selection of plant type, technological features, and financing options will play a key role in long-term success.

Investing in the right plant, backed by effective marketing, robust supply chains, and strategic partnerships, can establish your business as a leader in the tuff tile manufacturing sector.