Description

The Definitive Guide to Mobile Batching Plants for Sale in Pakistan – A Silver Steel Mills Imperative

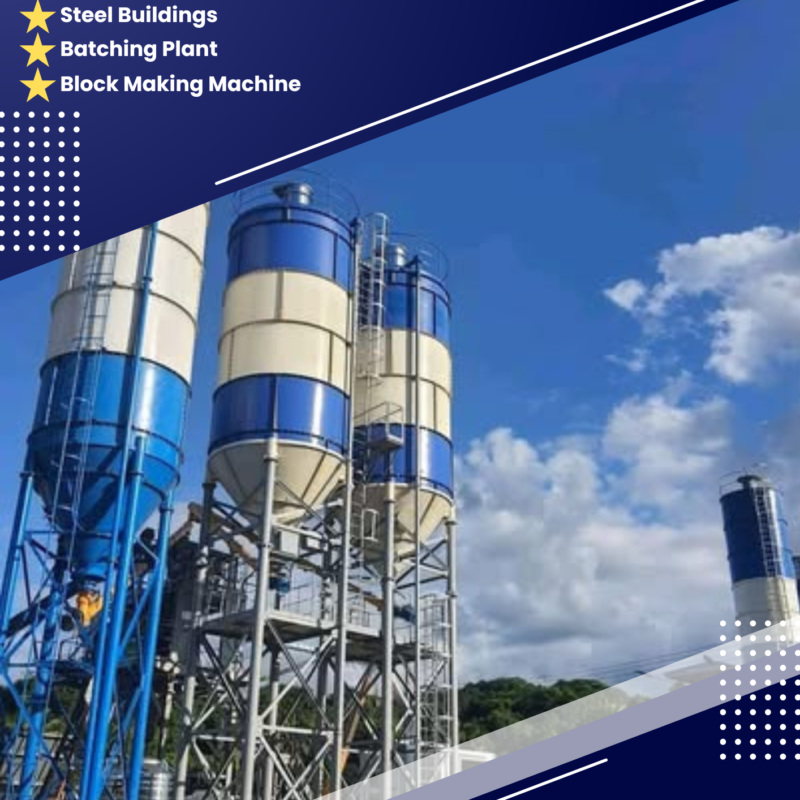

In the vibrant and rapidly evolving construction landscape of Pakistan, agility, efficiency, and uncompromising quality are the cornerstones of success. As infrastructure projects proliferate across diverse terrains, from expansive highways to intricate urban developments and remote community initiatives, the demand for adaptable concrete production solutions has surged. At the forefront of this revolution stands the mobile concrete batching plant, a marvel of engineering designed for rapid deployment, seamless relocation, and consistent, on-site concrete generation. For discerning contractors and developers, the search for a mobile batching plant for sale in Pakistan is more than an equipment acquisition; it’s an investment in project velocity, cost optimization, and unparalleled concrete excellence.

This comprehensive exposition will meticulously explore the profound advantages of mobile concrete batching plants, dissecting the critical factors that influence their pricing, performance, and long-term value. We will illuminate the strategic benefits these versatile units offer to Pakistan’s dynamic construction sector, while unequivocally championing Silver Steel Mills as the preeminent manufacturer. Our vertically integrated production process, anchored by our in-house, high-grade steel manufacturing capabilities, positions Silver Steel Mills not just as a supplier, but as a guarantor of superior quality, enduring reliability, and exceptional return on investment for every mobile batching plant deployed across the nation.

The Paradigm Shift: Why Mobile Batching Plants are Indispensable for Modern Pakistani Construction

Gone are the days when static, centralized concrete plants were the sole option for large-scale projects. While they retain their importance for continuous, high-volume ready-mix concrete supply, the distributed nature of modern infrastructure and real estate development in Pakistan demands a more flexible and responsive approach. The mobile concrete batching plant embodies this evolution, offering a dynamic solution to inherent logistical and operational challenges.

Overcoming Geographic and Logistical Hurdles

Pakistan’s diverse geography presents unique logistical challenges for construction. Transporting ready-mix concrete over long distances, especially to remote or congested urban sites, can lead to:

- Compromised Concrete Freshness: Extended transit times, particularly in hot climates, can cause concrete to begin setting or lose workability, impacting its strength and requiring costly admixtures or even rejection.

- Increased Transportation Costs: Fuel consumption, vehicle maintenance, and driver wages for long hauls significantly inflate the overall cost of concrete.

- Traffic Delays and Bottlenecks: Urban congestion or difficult terrain can lead to unpredictable delays, disrupting pouring schedules and affecting project timelines.

- Limited Accessibility: Many project sites, particularly for rural infrastructure or pipeline projects, are inaccessible to large transit mixers, making on-site production a necessity.

The mobile batching plant directly addresses these challenges by bringing the concrete production facility directly to the job site.

The Core Advantages: Agility, Efficiency, and Quality Control On-Demand

The compelling benefits of deploying a mobile concrete batching plant in Pakistan are multifaceted and directly contribute to project success:

- Unparalleled Mobility and Rapid Deployment: This is the quintessential advantage. Mounted on a robust, towable chassis, a portable concrete batch plant can be swiftly transported between sites. Its modular design allows for remarkably fast setup and dismantling, often within a single day. This means:

- Reduced Setup Time: Minimal civil work and no need for elaborate, permanent foundations, saving both time and substantial costs compared to stationary plants.

- Faster Project Initiation: Begin concrete production almost immediately upon arrival, eliminating delays associated with off-site concrete procurement.

- Versatile Application: Ideal for linear projects like highways, pipelines, and canals, where concrete demand shifts along a long corridor, or for multiple short-duration projects in various locations.

- Superior Concrete Freshness and Consistency: By producing concrete on-site, just moments before pouring, a mobile batching plant ensures the concrete retains its optimal workability, slump, and designed properties. This eliminates concerns about premature setting during transit, guaranteeing:

- Enhanced Structural Integrity: Consistently fresh concrete leads to optimal strength development and reduced risk of structural defects.

- Reduced Admixture Dependency: Less need for costly retarders or superplasticizers to maintain workability, saving material costs.

- Optimal Setting Times: Concrete performs as intended, facilitating smoother construction workflows.

- Significant Cost Savings and Optimized Logistics: The economic advantages extend beyond the initial mobile batching plant price:

- Elimination of Transit Mixer Costs: Drastically reduces or entirely negates the expense of hiring and operating a fleet of transit mixers for long hauls.

- Minimized Material Wastage: Precise, automated batching reduces spillage and over-usage of costly raw materials like cement and aggregates.

- Reduced Fuel Consumption: On-site production minimizes the need for fuel-intensive transportation of finished concrete.

- Lower Labor Costs: Automated systems reduce the dependency on extensive manual labor for mixing and handling.

- No Costly Foundations: Saves considerable expenditure on civil works and the concrete foundations required for stationary plants.

- Pinpoint Quality Control at the Source: Mobile plants, especially those equipped with modern automation systems, allow for real-time monitoring and adjustments to mix designs. This on-site control ensures:

- Precise Recipe Adherence: Every batch meets exact specifications, crucial for projects with stringent quality requirements.

- Immediate Adjustments: Ability to quickly modify concrete characteristics based on ambient temperature, aggregate moisture content, or specific pouring needs.

- Comprehensive Data Logging: Automated systems record every batch, providing invaluable data for quality assurance, auditing, and performance analysis.

- Enhanced Operational Flexibility and Project Autonomy: Owning a mobile batching plant grants projects greater independence from external ready-mix concrete suppliers. This autonomy translates into:

- Uninterrupted Supply: Ensures a continuous flow of concrete, even in remote areas or during peak demand, avoiding project delays due to supply chain issues.

- Scheduling Control: Ability to produce concrete precisely when and where it’s needed, optimizing pouring schedules and overall project timelines.

- Adaptability to Varied Projects: From road repairs and bridge construction to housing developments and precast element production, a mobile plant can adapt to diverse concrete needs.

- Reduced Environmental Footprint: By eliminating long-distance concrete transportation, mobile plants contribute to lower carbon emissions and reduced traffic congestion. Many modern units also incorporate features for dust suppression and water recycling, aligning with sustainable construction practices.

In essence, a mobile concrete batching plant is not just an asset for producing concrete; it’s a strategic tool for enhancing project efficiency, controlling costs, ensuring uncompromised quality, and delivering construction projects with unparalleled speed and precision across Pakistan’s varied terrain. Its inherent flexibility makes it an invaluable addition to any forward-thinking construction enterprise.

The Silver Steel Mills Mobile Advantage: Engineering Agility with Unshakeable Strength

When considering a mobile batching plant for sale in Pakistan, the market offers a diverse range of options. However, for those who prioritize enduring performance, unmatched reliability, and superior long-term value, Silver Steel Mills stands as the definitive choice. Our unique market position, rooted in our deep expertise as a premier steel manufacturer, provides an inherent, unassailable advantage in crafting mobile batching plants that are both agile and exceptionally robust.

The Cornerstone of Quality: Our In-House Steel Manufacturing

At the heart of every Silver Steel Mills mobile batching plant lies the profound strength derived from our vertically integrated production process. We don’t merely assemble components; we forge the very essence of durability. Our in-house steel mills produce the high-grade structural steel that forms the backbone of our machinery, offering critical benefits:

- Intrinsic Material Integrity: We exercise complete control over the metallurgical composition and properties of our steel. This ensures unparalleled tensile strength, yield strength, and toughness, critical for components that bear heavy loads, withstand constant vibration, and endure the rigors of frequent relocation.

- Superior Corrosion Resistance: Pakistan’s diverse climate, from arid plains to humid coastal regions, can be harsh on machinery. Our steel, combined with meticulously applied, multi-layer protective coatings, offers exceptional resistance to rust and environmental degradation. This significantly extends the plant’s operational lifespan, safeguarding your investment against premature wear and corrosion, a distinct advantage for a mobile concrete plant exposed to varying conditions.

- Precision Fabrication: Our steel is consistently dimensioned and highly workable, allowing our state-of-the-art fabrication facilities – equipped with CNC laser cutters, automated welding robots, and precision bending machines – to produce components with unmatched accuracy. This precision ensures seamless assembly, minimal tolerances, and optimal functional alignment, paramount for the quick setup and reliability of a portable concrete plant.

- Enhanced Durability for Mobility: The constant movement, setup, and dismantling inherent to mobile batching plants place immense stress on their structure. Our high-quality steel and superior fabrication techniques ensure that every Silver Steel Mills mobile unit is engineered to withstand these stresses, maintaining structural integrity and operational stability throughout its extensive service life.

Beyond Steel: The Engineering Prowess of Silver Steel Mills Mobile Plants

Our commitment to excellence extends far beyond our foundational steel. Every Silver Steel Mills mobile batching plant is a testament to sophisticated engineering and thoughtful design, optimized for the Pakistani context:

- Optimized Compact Design for Effortless Portability: Our mobile concrete batching plants are designed with a focus on maximum transportability. The entire unit, or its primary modules, are mounted on a heavy-duty chassis with axles and pneumatic tires, conforming to road transport regulations. This compact footprint allows for:

- Single-Trailer Transportation: Many of our popular models can be transported efficiently on a single standard truck trailer, significantly reducing logistical costs and complexities.

- Rapid Road Deployment: Minimizing the time and effort required to move from one project site to another.

- Quick and Simplified Installation (Plug-and-Play Capability): We engineer our mobile plants for minimal on-site preparation. Often requiring only a leveled, hardened ground or a simple concrete slab, they virtually eliminate the need for extensive, costly foundations. This “plug-and-play” capability means:

- Production in Hours: Your plant can be set up, calibrated, and ready to produce high-quality concrete within hours of arrival at the new site, accelerating project timelines.

- Reduced Manpower for Setup: Simplified assembly and connection points reduce the number of personnel and specialized equipment required for installation.

- Powerful and Efficient Mixing Technology: At the core of our mobile plants are robust mixers, predominantly our acclaimed JS series twin-shaft compulsory mixers. These mixers are chosen for their ability to:

- Produce Homogeneous Mixes Rapidly: Ensuring consistent, high-strength concrete for diverse applications.

- Handle Diverse Mix Designs: Capable of producing various concrete grades from standard to specialized, accommodating specific project needs.

- Offer Reliable Performance: Designed for continuous operation with minimal wear, even under challenging conditions.

- Advanced Fully Automatic Control Systems: Silver Steel Mills integrates cutting-edge automation into every mobile unit. Our PLC-based control systems, with user-friendly interfaces and robust software, ensure:

- Pinpoint Batching Accuracy: Electronic load cells precisely measure aggregates, cement, water, and admixtures, guaranteeing perfect mix ratios and minimizing material waste.

- Real-time Monitoring and Diagnostics: Operators can monitor every stage of the production process, detect anomalies, and access detailed production reports, enhancing quality control and operational transparency.

- Recipe Storage and Recall: Easily store and retrieve numerous concrete mix designs, ensuring consistency across different batches and projects.

- Optimized Aggregate and Cement Handling: Our mobile plants feature efficient aggregate feeding systems (e.g., skip hoist for compact models or integrated belt conveyors for higher capacities) and easily integrated cement silos.

- Flexible Silo Options: From compact, towable mobile concrete silo units to standard bolted silos, we provide solutions that match the plant’s mobility and site constraints.

- Efficient Material Flow: Engineered layouts minimize bottlenecks and ensure a smooth, continuous flow of raw materials.

Representative Silver Steel Mills Mobile Batching Plant Model: Power on the Move

While our full range of mobile batching plants is extensive, encompassing capacities from 25 m³/h to 100 m³/h, here’s an illustrative example of the core specifications you can expect from a typical Silver Steel Mills mobile concrete batching plant, showcasing our commitment to balanced performance and mobility:

Silver Steel Mills YHZS35 Mobile Batching Plant (Illustrative Example)

This plant, designed for optimal portability and efficient medium-scale production, represents a popular choice for contractors seeking agile and reliable concrete supply.

Note: Silver Steel Mills offers a complete range of mobile batching plants with varying capacities and configurations. This table is indicative of our design philosophy and quality standards across the mobile series.

By meticulously combining the robustness of our in-house steel with agile, intelligent engineering, Silver Steel Mills delivers mobile batching plants that are not only capable of withstanding the rigors of frequent relocation but also consistently deliver precise, high-quality concrete, making them an indispensable asset for modern construction in Pakistan.

The Financial Landscape: Understanding Mobile Batching Plant Price in Pakistan

The decision to acquire a mobile batching plant for sale in Pakistan inevitably involves a detailed financial analysis. While the initial mobile batching plant price is a critical consideration, a truly astute investment decision requires a comprehensive understanding of the factors that influence this cost and, more importantly, the long-term economic advantages that such an acquisition can unlock. Silver Steel Mills is committed to offering unparalleled value, balancing premium quality with competitive pricing to ensure a robust return on your investment.

Key Factors Influencing Mobile Batching Plant Price

The cost of a mobile concrete batching plant in Pakistan is a dynamic figure, shaped by a confluence of technical specifications, material choices, technological sophistication, and ancillary services. Key determinants include:

- Production Capacity (m³/h):

- This is the primary cost driver. A higher capacity mobile plant (e.g., 60 m³/h vs. 25 m³/h) necessitates larger, more powerful mixers, more extensive aggregate bins, larger cement silos, and a more robust structural frame, all of which directly increase manufacturing costs.

- The market for mini mobile concrete batching plant units (typically 20-35 m³/h) will generally see lower prices compared to medium (40-75 m³/h) or higher capacity (80-100 m³/h) mobile plants.

- Level of Automation:

- Semi-automatic vs. Fully Automatic: Fully automatic mobile plants, equipped with advanced PLC-based control systems, precise load cells for all ingredients, and sophisticated software for batching and reporting, will have a higher upfront cost than semi-automatic versions. However, this investment in automation translates into superior accuracy, consistency, reduced labor dependency, and minimized material waste, leading to significant long-term operational savings.

- Mixer Type and Quality:

- The type and quality of the mixer are paramount. High-efficiency twin-shaft compulsory mixers (like the JS series used by Silver Steel Mills) ensure homogeneous mixing and contribute significantly to the plant’s overall performance and durability, hence impacting the price. Planetary mixers, often used for specialized concrete, also influence the cost.

- Aggregate Feeding System:

- Most mobile plants utilize a skip hoist (bucket elevator) system for feeding aggregates due to its compact design, which is ideal for mobility. The capacity and robustness of this system contribute to the cost.

- Cement Silo Configuration:

- The capacity and type of cement silo (e.g., standard bolted silo requiring separate transport, or a mobile concrete silo designed for integrated transport with the plant) will affect the overall mobile batching plant price. Larger capacities or specialized mobile silos add to the cost.

- Brand Reputation and Manufacturer’s Expertise:

- Established manufacturers like Silver Steel Mills, with a proven track record of quality, engineering excellence, and reliable after-sales support, often price their products to reflect this superior value. While their initial price might be higher than unproven or lower-quality alternatives, the long-term total cost of ownership is significantly lower due to reduced breakdowns, less maintenance, and extended operational life.

- Quality of Components and Workmanship:

- The caliber of critical components (motors, gearboxes, sensors, electrical systems) and the overall fabrication quality (welding, painting, assembly) directly influence both the price and the longevity of the plant. Silver Steel Mills prioritizes premium components and meticulous workmanship.

- Inclusion of Optional Features and Customizations:

- Any specific add-ons such as integrated water chilling plants, advanced dust collection systems, specialized admixture dosing pumps, additional aggregate compartments, or customized control software will add to the mobile batching plant price. These features enhance functionality and efficiency but are factored into the final quotation.

- Ancillary Costs (Beyond Purchase Price):

- Freight and Logistics: While mobile plants reduce long-haul concrete transportation costs, the initial delivery of the plant to your site still incurs freight charges.

- Installation & Commissioning: Professional installation and calibration services ensure optimal performance.

- Civil Works: Although minimal compared to stationary plants, some ground preparation (leveling, hardening, basic power/water connections) may be required.

- Taxes and Duties: Applicable government taxes and duties will be added to the base price.

Silver Steel Mills: Delivering Unmatched Value in Mobile Concrete Production

Silver Steel Mills doesn’t compete on merely offering the lowest mobile batching plant price in Pakistan. Our strategy is centered on delivering superior long-term value, which translates into a robust return on investment for our clients. Here’s how we achieve this:

- Premium Quality, Optimized Investment: Our direct control over high-grade steel production means every structural element of our mobile batching plants is inherently superior. This translates to a plant that is exceptionally durable, capable of withstanding the rigors of frequent relocation and continuous operation for decades. While our initial pricing reflects this premium quality, it prevents costly premature wear, frequent repairs, and significant downtime – the hidden expenses often associated with cheaper, inferior imports. Your investment with Silver Steel Mills is a long-term asset, not a short-term liability.

- Enhanced Operational Efficiency, Reduced Running Costs: The precision engineering, advanced automation, and efficient mixing technology embedded in every Silver Steel Mills mobile plant directly reduce your operational expenditures. This includes minimizing material wastage through accurate batching, optimizing energy consumption, and reducing labor dependency. These cumulative savings over the plant’s operational lifetime far outweigh any minor upfront price differences.

- Strategic Local Manufacturing Advantage: As a local Pakistani manufacturer, Silver Steel Mills provides significant economic advantages. We eliminate the burden of high import duties, mitigate risks associated with volatile international currency exchange rates, and significantly reduce shipping times and costs. This local presence ensures more stable and competitive pricing for mobile concrete batching plant for sale in Pakistan, along with readily accessible support and spare parts, directly contributing to a lower total cost of ownership.

- Comprehensive After-Sales Support: Maximizing Uptime: Our commitment to your success extends beyond the sale. Our robust after-sales service, including expert installation, operator training, rapid technical assistance, and guaranteed availability of genuine batching plant parts, ensures maximum uptime for your mobile unit. This minimizes costly project delays and keeps your concrete production flowing seamlessly.

- Transparent and Client-Centric Pricing: We believe in absolute transparency. Our sales and engineering teams work closely with each client to understand their unique needs, providing detailed, itemized quotations that clearly outline the mobile batching plant price in Pakistan based on chosen specifications and optional features. We ensure you understand precisely where your investment is allocated and the value it delivers.

In essence, investing in a Silver Steel Mills mobile concrete batching plant is not just about the initial outlay; it’s about acquiring a strategic asset that consistently delivers high-quality concrete, optimizes project timelines, significantly reduces operational risks, and guarantees a superior return on investment over its long, productive lifespan. For the modern Pakistani construction industry, Silver Steel Mills represents the intelligent, durable, and economically sound choice for mobile concrete production.

Acquiring Your Agile Partner: The Silver Steel Mills Mobile Batching Plant Acquisition Journey

The decision to procure a mobile batching plant for sale in Pakistan is a strategic one, aimed at enhancing flexibility, efficiency, and quality in your construction operations. To ensure a seamless and rewarding experience, it’s crucial to partner with a manufacturer who understands your needs and delivers not just equipment, but a comprehensive solution. Silver Steel Mills’ acquisition journey is meticulously designed to provide unparalleled client support, from initial consultation to enduring after-sales partnership.

The Silver Steel Mills Client-Centric Acquisition Process:

- In-Depth Consultation & Needs Assessment:

- Your journey begins with a detailed discussion with our team of expert sales engineers and technical consultants. We delve deep into your project specifics: your anticipated concrete volume requirements, typical project durations, site accessibility, specific mix design needs, and target operational efficiency.

- We also assess your current logistical challenges and budgetary considerations to recommend the most suitable mobile concrete batching plant model and configuration. This thorough analysis ensures our solution perfectly aligns with your operational objectives.

- Tailored Solution Design & Transparent Quotation:

- Based on the comprehensive needs assessment, our engineering team will propose a customized mobile batching plant solution. This proposal will detail the recommended model (e.g., YHZS25, YHZS35, YHZS50, YHZS60, YHZS75, YHZS100), its precise specifications, automation level, and any recommended optional features (like a mobile concrete silo or advanced environmental controls).

- We provide a clear, itemized quotation that transparently outlines the mobile batching plant price in Pakistan, including any optional features, and explains all associated costs, ensuring complete clarity and no hidden surprises.

- Precision Manufacturing & Rigorous Quality Assurance:

- Upon your approval of the proposal and terms, the manufacturing process commences at our state-of-the-art facilities. Leveraging our in-house steel production, every component of your mobile batching plant is fabricated with exacting precision, employing advanced CNC machinery and automated welding techniques.

- Every stage of production undergoes stringent multi-point quality control checks. From raw material inspection to component assembly and final functional testing of the complete unit, we ensure that your mobile plant meets Silver Steel Mills’ renowned standards for durability, performance, and reliability before it leaves our factory.

- Efficient Logistics, Rapid Installation & Commissioning:

- We manage the streamlined and secure transportation of your mobile batching plant components to your designated project site anywhere in Pakistan. Our specialized logistics team ensures timely and safe delivery.

- Upon arrival, our highly skilled engineers and technicians promptly begin the installation and commissioning process. Designed for rapid deployment, a Silver Steel Mills mobile plant can typically be set up, calibrated, and ready for production within a single day, minimizing project delays and allowing you to commence concrete pouring almost immediately. This eliminates the lengthy setup times associated with conventional stationary plants.

- Comprehensive Operator Training & Seamless Handover:

- To ensure you maximize your investment, our experts conduct thorough, hands-on training for your operational and maintenance personnel. This covers safe operation procedures, efficient batching techniques, routine maintenance protocols, basic troubleshooting, and effective utilization of the automated control system. Our goal is to empower your team to confidently and independently operate your new Silver Steel Mills mobile batching plant.

- Enduring After-Sales Partnership & Support:

- Our commitment to your operational success is a long-term pledge. Silver Steel Mills provides an extensive after-sales support system:

- Prompt Technical Assistance: Our dedicated support team is available to resolve any technical queries or operational challenges, offering both remote and swift on-site intervention when necessary.

- Guaranteed Genuine Spare Parts: We maintain a substantial inventory of authentic batching plant parts, ensuring rapid availability for any replacements and minimizing costly downtime.

- Proactive Maintenance Programs: We offer flexible maintenance contracts and scheduled servicing to proactively identify and address potential issues, extending your plant’s lifespan and ensuring continuous peak performance.

- Our commitment to your operational success is a long-term pledge. Silver Steel Mills provides an extensive after-sales support system:

Why Silver Steel Mills Reigns Supreme for Mobile Batching Plants in Pakistan:

- Unmatched Durability from In-House Steel: No other manufacturer in Pakistan can match our vertical integration. Our own superior-grade steel guarantees structural integrity for the demanding nature of mobile operations.

- Engineered for Pakistani Conditions: Our designs are optimized to withstand the climate, terrain, and operational challenges unique to Pakistan’s construction sector.

- Rapid ROI through Efficiency and Reliability: Our mobile plants deliver consistent, high-quality concrete on-site, drastically reducing logistics costs, material wastage, and project timelines, leading to faster project completion and higher profitability.

- Local Support, Global Standards: While proudly Pakistani, our engineering and manufacturing adhere to international best practices, providing you with world-class equipment and local, responsive support.

- A Partner in Your Progress: We see ourselves as more than a supplier; we are an integral part of your growth story, providing the tools and support necessary for your sustained success in the competitive construction arena.

For construction companies, contractors, and developers across Pakistan seeking to embrace the future of agile concrete production, the choice is clear. A Silver Steel Mills mobile concrete batching plant is not just an asset; it is a strategic advantage, delivering power on the move, precision at your fingertips, and the unwavering reliability that only comes from a manufacturer deeply rooted in quality and client success.

Unlock the full potential of your construction projects. Contact Silver Steel Mills today for a personalized consultation and a detailed quotation for a mobile batching plant that will redefine your operational capabilities.

Visit our official website: silversteelmills.com

The development business in Pakistan has witnessed fast progress, leading to growing demand for cellular batching vegetation. Silver Metal Mills, a number one identify in development equipment, affords premium-quality cellular batching vegetation and associated options tailor-made to the dynamic wants of Pakistani builders and contractors. This text supplies an in-depth evaluation of cellular batching vegetation, exploring their varieties, costs, makes use of, and the function they play in Pakistan’s evolving infrastructure panorama.

Introduction to Batching Vegetation

A batching plant, also called a concrete batch plant or concrete mixing plant, is a facility used to mix varied substances like water, cement, sand, and gravel to type concrete. These vegetation are important for development initiatives requiring constant and high-quality concrete.

Kinds of Batching Vegetation

Silver Metal Mills affords a variety of batching vegetation, together with:

- Cellular Batching Plant

- Moveable Concrete Plant

- Mini Cellular Concrete Batching Plant

- Truck Mounted Concrete Batching Plant

- Concrete Mixing Plant

- Prepared Combine Concrete Plant

These machines cater to completely different venture scales and mobility wants. Cellular and moveable variations are particularly helpful for contractors working throughout a number of websites.

Cellular Batching Plant: Options and Benefits

A cellular concrete batching plant is a extremely environment friendly, moveable setup that may be relocated simply. These vegetation include a number of benefits:

- Fast setup and dismantling

- No basis required

- Straightforward transportation from one web site to a different

- Ideally suited for small to medium development initiatives

Why Select Silver Metal Mills?

Silver Metal Mills stands out for its reliability, high quality, and tailor-made options. Our cellular batching plant on the market in Pakistan is designed to satisfy worldwide requirements whereas being cost-effective and sturdy for native circumstances.

Key Options:

- Strong construction with galvanized parts

- PLC-controlled operation

- Environment friendly mixer system

- Water and additive dosing system

- Compact design with mobility

Batching Plant Worth in Pakistan

The batching plant value in Pakistan varies relying on specs, capability, and mobility. Silver Metal Mills affords aggressive pricing with out compromising on high quality.

| Kind | Estimated Worth Vary (PKR) |

|---|---|

| Mini Cellular Batching Plant | 3,500,000 – 5,000,000 |

| Cellular Concrete Batching Plant | 5,500,000 – 9,000,000 |

| Truck Mounted Batching Plant | 10,000,000 – 15,000,000 |

| Moveable Concrete Batch Plant | 4,500,000 – 7,500,000 |

Cellular Batching Plant Functions

- Residential development

- Street infrastructure

- Flyovers and bridges

- Actual property developments

- Distant or rural initiatives

Used Batching Vegetation for Sale

Silver Metal Mills additionally facilitates consumers on the lookout for used batching plant on the market choices. These are totally inspected and examined to make sure efficiency requirements.

Excessive-Performing Cellular Concrete Mixing Plant

Silver Metal Mills’ cellular concrete mixing plant ensures uniform concrete manufacturing with state-of-the-art mixing expertise.

Moveable Concrete Vegetation for Lease

We provide moveable concrete batch vegetation for hire to cater to short-term venture wants. This enables flexibility with out giant capital funding.

High Areas We Serve

We provide concrete batching vegetation in Pakistan to cities comparable to:

- Islamabad

- Lahore

- Karachi

- Faisalabad

- Multan

- Peshawar

- Quetta

Built-in Options: Block Machines, Tile Vegetation, and Fly Ash Bricks

Along with batching vegetation, Silver Metal Mills supplies full options:

Block Making Machines

Together with:

- Block making machine value in Pakistan

- Guide and computerized fashions

- Concrete block making machine value in Pakistan

Tuff Tile Plant Machines

- Tuff tile machine on the market in Pakistan

- Computerized tuff tile making machines

- Small tuff tile machine value in Pakistan

Fly Ash Brick Machines

- Used fly ash brick machine value in Pakistan

- Computerized and guide fashions

- Fly ash bricks machine value in Pakistan OLX

All machines can be found by way of Silver Metal Mills with wonderful buyer assist.

Skilled Backlinking for Authority

- Go to Silversteelmills.com for machine specs and orders.

- Discover provider connections at PakistaniWholesaler.com for bulk development tools inquiries.

Remaining Ideas

Investing in a cellular batching plant on the market in Pakistan is a brilliant transfer for contractors aiming for agility, high quality, and cost-efficiency. Silver Metal Mills is dedicated to supporting Pakistan’s development ecosystem with fashionable, high-performance, and budget-friendly options.