Description

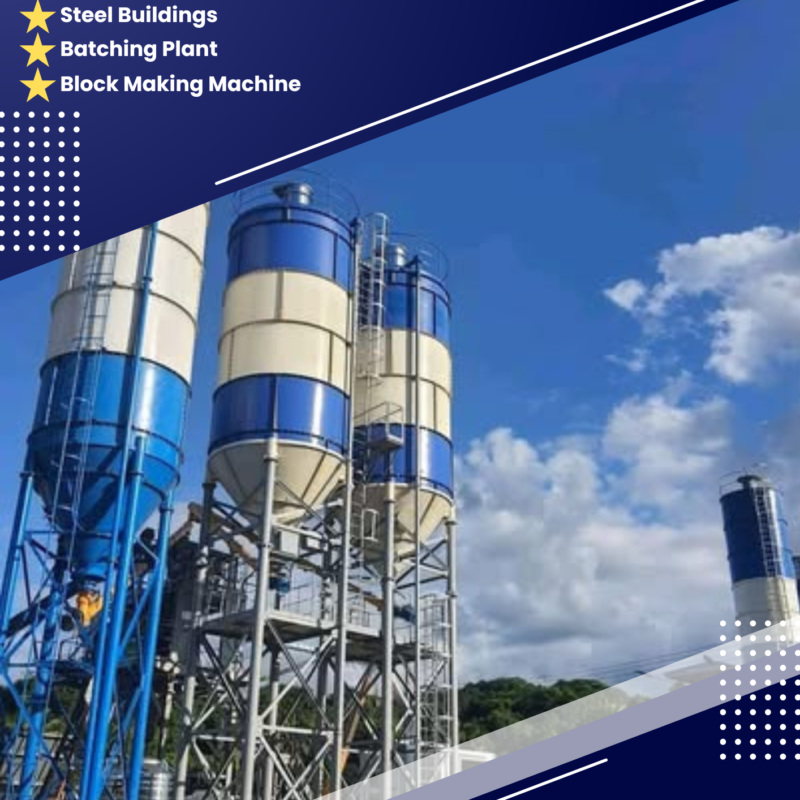

Batching Plant in Pakistan – Complete Guide for 2025

Introduction: The Growing Demand for Batching Plants in Pakistan

Pakistan’s construction sector is expanding at an unprecedented pace. From housing projects and industrial zones to government-backed infrastructure initiatives, the demand for reliable concrete supply chains is stronger than ever. At the heart of these supply chains are concrete batching plants. These plants ensure consistent, high-quality concrete production for everything from residential complexes to mega projects like motorways and industrial parks.

Silver Steel Mills (SSM), headquartered in Rawalpindi, is at the forefront of this transformation. As a trusted manufacturer and supplier of concrete batching plants in Pakistan, Silver Steel Mills provides cutting-edge solutions tailored to the unique needs of local builders and developers.

Why Concrete Batching Plants Are Essential in Pakistan’s Development

Pakistan faces increasing urbanization, government housing schemes, and CPEC-related projects, all requiring fast, durable construction solutions. Traditional manual mixing methods cannot keep up with these demands. Concrete batching plants address these needs through:

- Consistent Quality: Automated systems ensure uniform concrete strength and durability.

- Time Efficiency: Plants reduce mixing and delivery times, meeting tight project schedules.

- Cost Savings: Minimizing material waste and optimizing labor costs.

- Environmental Compliance: Modern plants use sustainable technologies, reducing dust and material loss.

From national highways to private housing developments, batching plants are indispensable tools that streamline project execution while maintaining quality.

Introduction: Understanding the Role of Batching Plants in Pakistan’s Construction Growth

Concrete batching plants are at the core of modern construction projects in Pakistan. With rapid urbanization, growing infrastructure demands, and the country’s emphasis on mega projects like highways, housing schemes, and industrial zones, batching plants have become indispensable. These plants automate the process of mixing cement, aggregates, water, and additives to produce consistent, high-quality concrete.

In Pakistan, the demand for efficient and durable batching plants has surged. Real estate developers, government contractors, and private construction firms all require reliable systems to meet strict timelines and quality standards. Silver Steel Mills (SSM) has emerged as one of Pakistan’s premier manufacturers and suppliers of concrete batching plants, offering products that combine cutting-edge technology, robust engineering, and affordable pricing.

Why Concrete Batching Plants Are Essential for Pakistan’s Infrastructure

- Speed and Efficiency: Manual concrete mixing is slow and inconsistent. Batching plants produce large volumes with consistent quality.

- Cost Control: Reduces material wastage and labor costs by automating the mixing process.

- Quality Assurance: Ensures uniform mixing, crucial for strength and durability in modern structures.

- Regulatory Compliance: Meets Pakistan’s building codes and safety standards for public and private sector projects.

- Eco-Friendly Construction: Modern batching plants optimize material use, contributing to green building practices.

Growing Sectors Requiring Batching Plants

- Government Housing Projects (e.g., Naya Pakistan Housing Program)

- CPEC-Linked Infrastructure (Motorways, Airports, Ports)

- Industrial Zones and Export Processing Areas

- Commercial Real Estate Developments

- Residential Complexes and Societies

Types of Batching Plants Available in Pakistan

Manual Batching Plants

- Best For: Small-scale, low-budget projects

- Pros: Low initial investment, simple operation

- Cons: Lower production capacity, higher labor dependency

Semi-Automatic Batching Plants

- Best For: Mid-sized housing projects and commercial buildings

- Pros: Balanced cost and efficiency, partial automation

- Cons: Still requires manual supervision

Fully Automatic Batching Plants

- Best For: Large-scale industrial, commercial, and infrastructure projects

- Pros: High productivity, consistent quality, minimal labor requirement

- Cons: Higher initial cost

Silver Steel Mills’ Batching Plant Range: Precision Engineering for Pakistan

Silver Steel Mills offers a full range of batching plants suited to all project sizes and budgets, all manufactured with ISO and CE certifications.

JS500 Batching Plant: Flagship Model for Mid-Scale Production

Overview

The JS500 is a twin-shaft horizontal forced mixer, widely adopted across Pakistan for its versatility and efficiency.

Key Features

- Twin Shaft Horizontal Forced Type Mixer

- Hydraulic Discharge with Manual Option

- High Wear-Resistant Chromium-Manganese Alloys Plates and Blades

- Multi-Sealing System to Prevent Leakage

- National Standard Steel Frame

- Full Copper Motors with Long Life

- Discharge Height Options: 1.5m or 3.8m

- Compliance with ISO and SGS Standards

JS500 Technical Specifications

| Specification | Detail |

|---|---|

| Discharging Capacity | 500L |

| Drum Capacity | 800L |

| Productivity | 25 m³/h |

| Max Aggregate Size | 40/50 mm |

| Mixing Blade Rotate Speed | 35 r/min |

| Mixing Blade Number | 2 x 7 |

| Motor Power | 18.5 kW |

| Dimension (Transport State) | 305025302680 mm |

| Dimension (Work State) | 446130504180 mm |

| Weight | 4000 kg |

Advantages of Choosing Silver Steel Mills

- High Mixing Evenness

- Low Maintenance Requirements

- Fast Delivery Nationwide

- Custom Mold and Capacity Options

After-Sales Service and Support

Silver Steel Mills provides:

- On-Site Installation and Commissioning

- Operator Training Programs

- Spare Parts Availability

- 24/7 Technical Support

Customization Options

- Capacity Adjustments (From JS500 up to JS2000)

- Discharge Height Customization

- Mold Customization for Specialized Projects

Batching Plant Price in Pakistan: Understanding Market Rates

Factors Affecting Price

- Type: Manual, Semi-Automatic, or Fully Automatic

- Capacity: Higher capacity = Higher price

- Brand: Local vs. Imported

- Material Quality: Frame steel, motor brand, control system

- Customization: Tailored specifications cost extra

- Location: Delivery costs vary’

Price Range (As of 2025)

| Plant Type | Estimated Price (PKR) |

| Manual | 1,200,000 – 2,500,000 |

| Semi-Automatic | 4,000,000 – 7,500,000 |

| Fully Automatic | 8,500,000 – 25,000,000 |

Note: Prices are indicative. Contact Silver Steel Mills for a precise quote.

Batching Plant for Sale in Pakistan: Why Silver Steel Mills is the Top Choice

Where to Buy?

- Direct from Silver Steel Mills Official Website: silversteelmills.com

- Authorized Dealers Across Pakistan

- Industrial Equipment Exhibitions and Trade Fairs

Why Choose Silver Steel Mills?

- In-House Manufacturing Facilities

- ISO-Certified Processes

- Competitive Pricing with No Middleman Markups

- Proven Track Record: Projects Across Lahore, Karachi, Islamabad

Sales Process

- Inquiry: Through Website or Call

- Consultation: Project Requirement Analysis

- Quotation: Transparent Pricing Breakdown

- Manufacturing: Customization if Required

- Delivery & Installation: Site Preparation, Machine Setup

- Training: Operator Instruction Sessions

- After-Sales Support: Regular Maintenance and Spare Parts

Frequently Asked Questions

1. What is the best batching plant for a small housing project?

JS500 or a semi-automatic plant from Silver Steel Mills is ideal.

2. How long does delivery take?

Between 7–30 days, depending on the model and customization.

3. Does Silver Steel Mills provide installation?

Yes, full on-site installation and operator training.

4. How do I get a price quotation?

Visit silversteelmills.com or call the sales hotline.

5. Are spare parts easily available?

Yes, Silver Steel Mills maintains local stock for key components.

6. What type of warranty is offered?

Typically 1-year warranty with extended service options.

7. Can batching plants be exported outside Pakistan?

Yes. SSM batching plants are exported to Middle East and Central Asia markets.

8. How does JS500 compare to imported plants?

Comparable performance, better local support, lower pricing.

9. Can Silver Steel Mills customize plant sizes?

Absolutely. Tailored solutions are part of SSM’s service offering.

10. Is financing available?

SSM can assist with leasing and financing partnerships.

Conclusion: Building Pakistan’s Future with Silver Steel Mills

Concrete batching plants are essential for modern construction. From small residential buildings to large industrial complexes, Pakistan’s infrastructure growth depends on consistent, high-quality concrete production. Silver Steel Mills stands as the reliable, locally manufactured solution.

With world-class manufacturing, full after-sales support, competitive pricing, and ISO-certified quality, Silver Steel Mills remains the top choice for batching plants in Pakistan.

For the latest models, pricing, and availability, visit silversteelmills.com or contact their sales team directly. Invest in reliable machinery today and help shape Pakistan’s construction future with Silver Steel Mills.

Types of Batching Plants Available in Pakistan

Silver Steel Mills offers various types of concrete batching plants designed to meet different scale and budget requirements:

1. Manual Batching Plants

- Ideal for: Small contractors, village-level projects.

- Advantages: Low initial investment, simple operation.

- Limitations: Higher labor cost, limited production speed.

2. Semi-Automatic Batching Plants

- Ideal for: Medium-sized residential and commercial projects.

- Advantages: Balance between cost, productivity, and automation.

3. Fully Automatic Batching Plants

- Ideal for: Large-scale infrastructure and industrial projects.

- Advantages: Maximum efficiency, minimal manual intervention, precision mixing.

Silver Steel Mills’ Batching Plant Range

Silver Steel Mills specializes in manufacturing high-performance batching plants customized for Pakistan’s climate and construction standards.

JS500 Concrete Batching Plant Specifications

| Specification | Details |

|---|---|

| Model | JS500 |

| Discharging Capacity | 500 Liters |

| Drum Capacity | 800 Liters |

| Productivity | ≥ 25 m³/hour |

| Max Aggregate Size | 40/50 mm |

| Cycle Time | 72 Seconds |

| Dimensions (Transport) | 3050x2530x2680 mm |

| Dimensions (Work) | 4461x3050x4180 mm |

| Weight | 4000 kg |

| Mixing Blade Speed | 35 RPM |

| Mixing Motor Power | 18.5 kW |

| Winch Motor Power | 5.5 kW |

| Water Pump Motor Power | 1.1 kW |

| MOQ | 1 Set |

| Delivery Time | 7–30 Days |

Advantages of Buying from Silver Steel Mills

- ISO and CE Certified Machinery

- Locally Manufactured: Lower costs and faster delivery.

- Premium Materials: High-wear-resistant steel, full copper motors.

- Customization: Mold sizes, discharge heights, motor configurations.

- Installation & Commissioning: On-site setup and staff training.

After-Sales Service and Support

- 24/7 Technical Support

- Availability of Genuine Spare Parts

- Operator Training Programs

- Regular Maintenance Services

Customization Options

Silver Steel Mills understands that every project is unique. Custom features available include:

- Hydraulic or manual discharging options

- Multi-sealing systems for shaft end protection

- Different capacity options beyond JS500 model

Batching Plant Price in Pakistan

Pricing for batching plants in Pakistan depends on multiple factors:

- Type of Plant: Manual, semi-automatic, or fully automatic.

- Capacity: From 15 m³/hour to 120 m³/hour.

- Brand and Origin: Local vs. imported components.

- Delivery and Installation Costs: Vary by city and plant size.

Approximate Price Ranges:

- Manual Batching Plant: PKR 2,500,000 – 4,000,000

- Semi-Automatic Plant: PKR 4,500,000 – 8,000,000

- Fully Automatic Plant (Like JS500): PKR 8,000,000 – 15,000,000

Silver Steel Mills offers financing options and consultation services to help clients choose the best model within their budget.

Batching Plant for Sale in Pakistan

Silver Steel Mills provides complete solutions for acquiring batching plants:

- Factory Direct Sales: Lower prices and genuine warranty.

- Customized Orders: Tailored to client needs.

- Export Services: Shipping available to Gulf countries and Central Asia.

- Showroom Visits: Clients can inspect machinery before purchase.

The Buying Process:

- Initial Consultation: Discuss project size, timeline, and budget.

- Technical Proposal: Receive customized machine specifications.

- Quotation and Agreement: Transparent pricing with no hidden costs.

- Manufacturing and Delivery: 7–30 days lead time.

- Installation and Training: On-site commissioning and operator training.

Frequently Asked Questions

- What is the best batching plant model for residential projects in Pakistan? JS500 semi-automatic plant offers an ideal balance of price and productivity.

- Does Silver Steel Mills offer warranties? Yes, standard 1-year warranty with extended service contracts available.

- How long does installation take? Between 2–5 days, depending on the plant size.

- Can Silver Steel Mills customize mold sizes? Yes, customization is available.

- Is financing available? Financing and lease-to-own plans are available for eligible clients.

- Where is Silver Steel Mills located? Rawalpindi, Pakistan.

- What are the maintenance requirements? Monthly checks on hydraulic systems, blades, and motors.

- Can batching plants be relocated? Yes, mobile models are available.

- What is the lead time for a custom order? 7–30 days.

- Are parts locally available? Yes, full spare parts inventory is maintained.

Conclusion

Silver Steel Mills is a trusted name in Pakistan’s concrete batching plant industry. With certified products, customization options, and comprehensive after-sales support, SSM ensures clients receive maximum value for their investment.

For the latest prices, models, and expert consultation, visit:

The development {industry} in Pakistan is evolving quickly, and one of many key driving forces behind this transformation is the growing demand for high-performance concrete batching vegetation. As city infrastructure grows and residential and business initiatives surge, the necessity for contemporary and automatic batching options has develop into essential. At Silver Metal Mills, we offer cutting-edge, domestically manufactured concrete batching plant options designed to ship top-tier high quality, affordability, and long-term worth for building corporations throughout Pakistan.

Why Select a Concrete Batching Plant?

Concrete batching vegetation are important for mixing concrete elements precisely, making certain the sturdiness and energy of ultimate building constructions. These vegetation assist in producing excessive volumes of constant and high quality concrete, lowering handbook labor, growing effectivity, and minimizing waste.

Forms of Concrete Batching Vegetation Provided by Silver Metal Mills

Silver Metal Mills focuses on a spread of concrete batching plant fashions, together with:

- Cellular Concrete Batching Vegetation – Straightforward to move and set up, perfect for short-term or distant website initiatives.

- Mini Cellular Batching Vegetation – Compact and cost-effective, greatest fitted to small-scale building.

- Automated Concrete Batching Vegetation – Absolutely automated techniques with superior controls for max effectivity.

- Transportable Concrete Vegetation – Versatile and environment friendly options for contractors requiring mobility.

Every mannequin is designed to satisfy particular building wants, from high-rise buildings to highway improvement and infrastructure enlargement.

Concrete Batching Plant Worth in Pakistan

The concrete batching plant value in Pakistan varies based mostly on plant kind, capability, automation degree, and added options. Silver Metal Mills provides extremely aggressive pricing, custom-made to suit each undertaking price range. Right here’s a normal overview:

| Plant Sort | Worth Vary (PKR) |

|---|---|

| Mini Cellular Batching Plant | 7,500,000 – 8,500,000 |

| Cellular Batching Plant | 9,800,000 – 117,000,00 |

| Automated Concrete Plant | 11,000,000 – 120,000,00 |

| Transportable Concrete Plant | 9,500,000 – 9,900,000 |

All machines are manufactured utilizing high-quality elements, with after-sales service and set up supplied by our skilled engineers.

Benefits of Silver Metal Mills Batching Vegetation

- Sturdiness & Energy – Engineered to carry out below the hardest job website circumstances.

- Native Manufacturing – Higher spare half availability and cost-effective upkeep.

- Customization – We design options based mostly on particular necessities and undertaking scopes.

- Technical Help – 24/7 help and on-site help from educated technicians.

Further Building Equipment from Silver Metal Mills

Alongside batching vegetation, we additionally provide:

- Block Making Machines

- Tuff Tile Vegetation

- Fly Ash Bricks Machines

- Paver Machines

All our machines can be found on the market in Pakistan and are optimized for top return on funding.

Splendid For:

- Authorities and Personal Contractors

- Street and Freeway Building Initiatives

- Residential and Business Builders

- Actual Property Builders

Excessive-High quality website positioning Backlinks

We advocate trying out high-authority native sources like:

- www.silversteelmills.com – Our official web site for product particulars.

- www.pakistaniwholesaler.com – Trusted supply for industrial equipment listings in Pakistan.

These backlinks not solely assist in website positioning optimization but additionally information potential consumers to dependable and genuine platforms.

Last Ideas

Investing in a concrete batching plant is a strategic determination that may considerably improve your building capabilities. At Silver Metal Mills, we’re devoted to offering industry-leading machines, backed by sturdy after-sales help, to make sure most uptime and profitability for your enterprise.

Unveiling the True Cost of Concrete Excellence: A Deep Dive into Batching Plant Prices in Pakistan, Championing Silver Steel Mills’ Unrivaled Value

In the dynamic tapestry of Pakistan’s burgeoning infrastructure and real estate sectors, concrete stands as the bedrock upon which progress is meticulously built. Every towering skyscraper, every sprawling road network, and every vital bridge relies on the consistent, high-quality production of this fundamental construction material. At the nexus of this critical process lies the concrete batching plant, a sophisticated industrial marvel that transforms raw aggregates, cement, water, and admixtures into the lifeblood of modern development. As the nation accelerates its development initiatives, the conversation around the batching plant price in Pakistan transcends a mere financial figure; it becomes an intricate analysis of investment, long-term value, and operational supremacy.

The market for a batching plant for sale in Pakistan is vibrant, populated by a spectrum of offerings from basic setups to highly automated systems. However, discerning buyers understand that the initial acquisition cost is but one facet of the total economic landscape. True value emerges from the confluence of a plant’s inherent quality, its operational efficiency over time, its resilience against challenging conditions, and the unwavering support provided by its manufacturer. This in-depth exposition will meticulously dissect the multifaceted factors that shape batching plant prices in Pakistan, while unequivocally spotlighting Silver Steel Mills as the preeminent manufacturer and supplier offering unparalleled value, driven by its unique, vertically integrated production process and an unwavering commitment to client success.

Deconstructing the Economic Fabric: Why Concrete Batching Plants are Indispensable for Pakistan’s Growth Trajectory

The narrative of Pakistan’s economic growth is inextricably linked to its infrastructure development. From the ambitious CPEC projects that redefine national connectivity to the rapid urbanization demanding new housing schemes and commercial hubs, the sheer volume and precision required for concrete production have rendered traditional methods obsolete. Modern concrete batching plants are not just machines; they are strategic assets that underpin the very foundation of this progress.

The Paradigm Shift from Primitive to Precision

For generations, concrete mixing on construction sites was a laborious, imprecise affair. Manual labor, rudimentary measuring techniques, and batch-by-batch inconsistencies were the norm. This often resulted in:

- Compromised Structural Integrity: Variations in mix ratios directly impact concrete strength and durability, leading to potential structural weaknesses, costly reworks, and safety concerns.

- Protracted Project Timelines: The slow pace of manual mixing created bottlenecks, extending project durations and incurring significant financial penalties due to delays.

- Escalated Material Wastage: Inaccurate measurements and spillage were endemic, leading to substantial losses of expensive raw materials like cement and aggregates, inflating overall project costs.

- Increased Labor Dependency & Costs: A large workforce was required, contributing to higher operational expenditures and complex labor management challenges.

- Limited Technical Specificity: Achieving precise concrete grades or incorporating specialized chemical admixtures for enhanced properties (e.g., waterproofing, rapid hardening, increased slump retention) was virtually impossible, limiting the scope of advanced construction.

The advent of the concrete batching plant represented a revolutionary paradigm shift. These automated or semi-automated facilities brought unparalleled precision, speed, and consistency to concrete production, addressing every critical limitation of manual methods.

Pillars of Progress: How Batching Plants Bolster Pakistan’s Development

The strategic deployment of advanced batching plants in Pakistan provides a multitude of benefits that are pivotal for the nation’s infrastructural ambitions:

- Guaranteeing Unblemished Concrete Quality and Consistency: The paramount advantage of a modern batching plant lies in its ability to produce concrete that is uniformly consistent across all batches. Utilizing sophisticated load cells for precise weighing of aggregates, cement, water, and chemical admixtures, coupled with computer-controlled mixing sequences, every cubic meter of concrete adheres flawlessly to the specified design mix. This unyielding consistency is non-negotiable for ensuring the structural integrity, long-term durability, and aesthetic appeal of any construction. This level of precision is particularly vital when delivering ready mix concrete in Pakistan for high-stakes projects where quality cannot be compromised.

- Accelerating Construction Timelines with High Production Capacities: Modern construction thrives on speed. Batching plants, from compact mini mobile concrete batching plant models producing 20-30 m³/h to massive stationary ready mix batching plant configurations churning out hundreds of cubic meters per hour, are engineered for high-volume, continuous output. This rapid production capability significantly compresses project schedules, allowing for quicker completion and faster monetization of investments. This efficiency directly translates into reduced overheads and enhanced competitiveness for contractors bidding on large-scale governmental or private projects.

- Minimizing Resource Consumption and Waste: Automated batching systems meticulously measure ingredients, drastically reducing over-usage and spillage inherent in manual processes. This precision translates into significant savings on costly raw materials like cement and aggregates. By minimizing waste, batching plants also contribute to more sustainable construction practices, aligning with national and global environmental objectives.

- Optimizing Long-Term Operational Economics: While the initial batching plant price in Pakistan can represent a substantial capital outlay, the long-term economic advantages are compelling. Reduced material wastage, lower labor dependency (due to automation), accelerated project completion, and the production of consistently high-quality concrete (minimizing rework and structural issues) cumulatively lead to a dramatically lower total cost of ownership and a robust return on investment.

- Empowering Versatility in Concrete Engineering: Modern batching plants offer remarkable flexibility. Operators can effortlessly adjust mix designs to produce an array of concrete types – from ultra-high strength concrete for specialized applications, self-compacting concrete for intricate forms, to lightweight concrete for reduced structural loads, and mixes incorporating various admixtures for enhanced workability, durability, or curing times. This adaptability is critical for meeting the diverse and evolving demands of contemporary construction blueprints.

- Enhancing Worksite Safety and Environmental Stewardship: By centralizing and automating the mixing process, batching plants reduce manual handling of heavy and potentially hazardous materials, thereby significantly improving worksite safety. Furthermore, many advanced plants incorporate features such as dust suppression systems, noise reduction enclosures, and water recycling mechanisms, contributing to a reduced environmental footprint and fostering greener construction practices in urban centers like batching plant in Pakistan Karachi or concrete batching plant in Islamabad.

- Ensuring Uninterrupted Supply for Megaprojects: For large-scale infrastructure ventures, a dedicated, high-capacity concrete batching plant provides an indispensable, uninterrupted supply of concrete, eliminating logistical bottlenecks and reliance on external suppliers for every batch. This guarantees project continuity and adherence to tight deadlines.

In summation, the concrete batching plant is not merely a piece of equipment; it is an economic catalyst. Its role in delivering consistent quality, accelerating project timelines, and optimizing resource utilization is pivotal for Pakistan’s sustained growth and the successful realization of its ambitious developmental agenda.

Navigating the Spectrum: Types of Batching Plants Tailored for Pakistan’s Diverse Needs

The multifaceted nature of Pakistan’s construction industry, encompassing everything from intricate urban developments to vast rural infrastructure projects, necessitates a diverse array of concrete batching plant solutions. Recognizing this crucial need, leading manufacturers like Silver Steel Mills offer a comprehensive portfolio, each type meticulously engineered to optimize efficiency, quality, and cost-effectiveness for specific applications. These plants are primarily differentiated by their operational methodology and mobility.

1. Stationary Concrete Batching Plants: The Stalwarts of High-Volume Production

Stationary batching plants are robust, high-capacity installations designed for long-term, continuous concrete production at a fixed site. They are the workhorses of large-scale construction enterprises and the backbone of the ready mix concrete (RMC) industry, efficiently supplying concrete to multiple projects within a defined geographical radius.

- Defining Characteristics:

- Immense Production Capacity: Typically ranging from 60 cubic meters per hour (m³/h) to over 240 m³/h, these plants are built for relentless, high-volume output.

- Formidable Structural Design: Constructed with heavy-duty, reinforced steel frames, stationary plants often require substantial, permanent concrete foundations for optimal stability and vibration damping.

- Advanced Automation and Control: Almost exclusively equipped with fully automatic, PLC (Programmable Logic Controller) or SCADA (Supervisory Control and Data Acquisition) based control systems, ensuring unparalleled precision in weighing, mixing, and dispensing, and comprehensive data logging.

- Exceptional Durability and Longevity: Engineered for continuous, arduous operation, these plants, particularly when fabricated with premium steel (like that from Silver Steel Mills), offer an extended operational lifespan with minimal wear and tear.

- Optimal Applications: Grand-scale infrastructure projects (such as major highways, extensive bridge networks, dams, power plants, and large-scale industrial complexes), major commercial and residential development schemes, and dedicated commercial ready mix concrete supply companies.

- Market Context: Discussions around concrete batching plant price in Pakistan for stationary units often revolve around the significant initial investment justified by the long-term return on investment from high capacity, superior concrete quality, and operational consistency. These are foundational assets for the ready mix concrete plant for sale market.

2. Mobile Concrete Batching Plants: The Epitome of Agility and Versatility

Also widely known as portable concrete plant or mobile batching plant, these units are ingeniously designed for maximum flexibility, rapid deployment, and easy relocation. They are mounted on a robust towable chassis, allowing for swift transportation between diverse project locations.

- Defining Characteristics:

- Effortless Portability: Engineered for quick dismantling, transport (often on a single or a few trailers), and rapid reassembly at a new site, significantly reducing relocation time and costs.

- Flexible Production Capacity: Typically ranging from 25 m³/h to 100 m³/h, making them suitable for a broad spectrum of small-to-medium-sized projects.

- Minimal Site Preparation: Often require only a leveled, hardened ground or a minimal concrete slab, substantially cutting down on expensive and time-consuming foundation work.

- Integrated, Compact Design: Many core components (mixer, aggregate bins, control cabin, weighing systems) are pre-installed on a single or interconnected chassis, facilitating quick setup and commissioning.

- Optimal Applications: Road construction (especially linear projects), bridge and culvert construction, remote site operations, short-term contracts, pipeline laying, and projects where concrete supply needs are distributed across multiple, geographically dispersed locations.

- Market Context: The demand for a mobile concrete batching plant is surging due to its inherent advantages in cost-effectiveness (reduced logistics, no permanent foundations), speed of deployment, and on-site production capability. Buyers often look for a mobile batching plant for sale or even explore mobile batching plant for rent for project-specific needs. Key phrases include portable concrete plant, mobile concrete plant for sale, portable concrete batch plant for sale, and for specific scales, mini mobile batching plant.

3. Compact Concrete Batching Plants: Bridging Capacity and Adaptability

Compact plants represent a strategic middle-ground, harmonizing the high capacity often associated with stationary units with a degree of transportability. They feature a modular, optimized design that allows for relatively easier relocation and quicker setup compared to traditional stationary plants, without a significant compromise on output.

- Defining Characteristics:

- Modular Construction: Components are designed for streamlined assembly and disassembly, facilitating easier transport.

- Optimized Footprint: Require a smaller site area compared to large stationary plants, making them ideal for space-constrained urban construction zones.

- Substantial Production Capacity: Can offer capacities ranging from 40 m³/h to 80 m³/h, adequate for many medium-to-large projects.

- Optimal Applications: Urban construction projects with limited available space, precast concrete manufacturing facilities, and situations demanding a balance between high output and some degree of transport flexibility.

4. Categorization by Automation Level: Precision at Your Fingertips

Beyond mobility, batching plants are also critically defined by their degree of automation, which directly impacts precision, labor requirements, and consistency:

- Manual Batching Plants: These rudimentary setups rely heavily on manual labor for the measurement and feeding of raw materials. While they have the lowest initial batching plant price in Pakistan, they suffer from inherent imprecision, slower production rates, and greater susceptibility to human error. Best suited for very small, infrequent projects where precision is not paramount.

- Semi-Automatic Batching Plants: These plants integrate some automated weighing systems for aggregates and cement but may still require manual intervention for water, admixtures, or material feeding/discharge. They offer a better balance between initial cost and improved efficiency/consistency compared to fully manual systems.

- Fully Automatic Batching Plants: These represent the pinnacle of modern batching technology. They feature sophisticated computer-controlled systems (PLC/SCADA) that orchestrate the entire production process from material feeding and precise weighing to mixing and discharge, with minimal human oversight. They guarantee the highest levels of accuracy, consistency, efficiency, and real-time data logging, making them the preferred choice for high-quality ready mix concrete production and projects demanding strict material control.

Silver Steel Mills: Engineering Excellence Across All Variants

Irrespective of the type or level of automation, Silver Steel Mills’ unwavering commitment to engineering superiority permeates every batching plant we manufacture and supply. Our foundational strength in steel fabrication means that the structural integrity, inherent durability, and optimal operational efficiency of all our plants – from the most compact mini mobile batching plant to the largest stationary unit – are second to none. We understand that the enduring performance of a concrete batching plant is intrinsically linked to the caliber of its steel components. This fundamental belief, coupled with our expertise in precision manufacturing, distinguishes Silver Steel Mills as a paramount batching plant manufacturer in Pakistan, delivering robust and reliable solutions for every construction endeavor.

Silver Steel Mills’ Unrivaled Batching Plant Range: Where Precision Meets Power

Silver Steel Mills is not merely a supplier; we are a vertically integrated powerhouse that defines excellence in steel manufacturing and extends this mastery into the realm of concrete batching plants. Our position as a premier batching plant manufacturer in Pakistan is solidified by our unique ability to control the quality of the raw materials – high-grade steel – that form the very backbone of our machinery. This intrinsic control, combined with cutting-edge engineering, advanced fabrication techniques, and an unyielding dedication to performance, allows us to offer a range of batching plants that epitomize precision, power, and long-term reliability.

Our philosophy centers on delivering more than just equipment; we provide comprehensive concrete production solutions. Each batching plant in our portfolio is designed to meet the rigorous demands of the Pakistani construction market, from the scorching plains to the humid coastal regions, ensuring consistent and optimal performance.

Our Exemplary Offerings: Designed for Diverse Applications

Silver Steel Mills offers a meticulously curated portfolio of batching plants, encompassing both high-capacity stationary units and agile mobile configurations. While our full range is extensive, we pride ourselves on models that feature our renowned JS series twin-shaft compulsory mixers, which are celebrated for their unparalleled mixing efficiency and homogeneity.

Let’s explore the core specifications and features that exemplify the quality and capability embedded in Silver Steel Mills’ batching plant range, focusing on a representative model like a JS Series equipped plant, which forms the heart of our medium-capacity solutions.

Silver Steel Mills HZS25-JS500 Batching Plant Specifications (Illustrative Example)

This plant, featuring the robust JS500 twin-shaft mixer, is a popular choice for its balance of capacity and operational efficiency, making it an excellent investment for many medium-scale projects and emerging ready-mix concrete suppliers.

Note: This table provides an illustrative example. Silver Steel Mills manufactures a complete spectrum of batching plants, including the larger HZS50, HZS75, HZS90, HZS120, and mobile plant equivalents, all built with the same commitment to precision and durability.

The Silver Steel Mills Advantage: Why Our Batching Plants Stand Apart

When evaluating a batching plant for sale in Pakistan, the decision extends beyond mere price tags. It’s about securing a strategic asset that consistently delivers performance, reliability, and value. Silver Steel Mills’ distinct competitive advantages make us the premier choice:

- In-House Steel Manufacturing: The Ultimate Quality Control Edge: This is our most significant differentiator. As a leading producer of high-grade steel in Pakistan, we maintain complete vertical integration over the most critical raw material of a batching plant. This allows us to:

- Guaranteed Material Purity & Strength: We control the metallurgical composition, ensuring our steel meets or exceeds international standards for tensile strength, yield strength, and toughness. This translates to structural components (frames, bins, supports) that can withstand immense operational stresses, vibrations, and heavy loads for decades.

- Superior Corrosion Resistance (with Treatment): The inherent quality of our steel, combined with our rigorous surface preparation and coating processes (e.g., multi-layer epoxy, specialized primers), provides exceptional resistance to rust and environmental degradation common in humid or chemically aggressive concrete environments. This significantly extends the plant’s operational life, particularly for components exposed to raw materials or harsh weather.

- Precision Fabrication: Our steel is consistently dimensioned and highly workable, enabling our state-of-the-art fabrication facilities (equipped with CNC laser cutters, automated welding robots, and precision bending machines) to produce components with unmatched accuracy. This precision ensures seamless assembly, minimized tolerances, and optimal functional alignment throughout the plant.

- Cost Efficiency (Internal): While we don’t compromise on quality, our in-house steel production optimizes our cost structure, allowing us to offer superior-grade plants at a more competitive batching plant price in Pakistan compared to manufacturers reliant on external, sometimes fluctuating, raw material markets.

- Exemplary Engineering & Design Philosophy: Our batching plants are not simply assembled; they are intelligently engineered. Our team of seasoned mechanical, electrical, and control system engineers leverages advanced CAD/CAM software for meticulous design, structural analysis, and optimization. This ensures:

- Structural Integrity & Safety: Designs are rigorously tested for load-bearing capabilities, seismic resilience (relevant for certain regions in Pakistan), and operational safety, complying with international safety standards.

- Operational Efficiency: Layouts are optimized for smooth material flow, easy access for maintenance, and ergonomic operation, minimizing bottlenecks and maximizing throughput.

- Energy Efficiency: Motors, drive systems, and control logic are selected and integrated to optimize power consumption, contributing to lower operational costs over the plant’s lifetime.

- Advanced Manufacturing Processes for Uncompromising Quality: Our production facilities are a testament to modern industrial excellence. We employ:

- Automated Welding: Robotic welding ensures consistent, high-strength welds that eliminate human error and enhance structural integrity.

- Precision Cutting & Bending: CNC machines guarantee exact dimensions and perfect fits for all components, crucial for seamless assembly and long-term stability.

- Multi-Stage Quality Control: Every component and sub-assembly undergoes stringent quality checks at each stage of production, culminating in comprehensive functional testing of the complete batching plant before dispatch.

- Tailored Solutions for Local and Regional Demands: Our profound understanding of the Pakistani construction landscape allows us to design plants optimized for local conditions:

- Aggregate Variability: Our plants are designed to handle the diverse types and gradations of aggregates found across Pakistan.

- Climatic Resilience: Components and systems are chosen to withstand extreme temperatures, high humidity, and dusty environments.

- Power Supply Adaptability: Electrical systems are configured for compatibility with local grid variations.

- Automation as a Catalyst for Precision and Productivity: Silver Steel Mills’ batching plants are equipped with intuitive, fully automatic control systems. These sophisticated PLCs, often integrated with industrial PCs and proprietary software, offer:

- Pinpoint Accuracy: Automated weighing and dosing ensure every ingredient is measured to within ±1% or better, guaranteeing consistent concrete quality.

- Seamless Operation: From material feeding to mixer discharge, the entire process is automated, minimizing manual intervention and human error.

- Real-time Monitoring & Diagnostics: Operators can monitor all parameters in real-time, diagnose issues quickly, and access detailed production reports, enhancing management and accountability.

- Recipe Management: Storage and recall of numerous concrete mix designs for efficient production of various grades.

Comprehensive After-Sales Service and Support: Our Pledge to Your Uptime

At Silver Steel Mills, we understand that the acquisition of a concrete batching plant is a long-term investment. Our commitment to your operational success extends far beyond the point of sale. Our robust after-sales service and support infrastructure are meticulously designed to ensure maximum uptime, optimal performance, and longevity for your plant. We view ourselves as your enduring partner in concrete production.

Our multifaceted after-sales support program includes:

- Expert Installation and Commissioning: Our highly trained and experienced engineers and technicians provide comprehensive on-site installation and commissioning services. We ensure that your batching plant is meticulously assembled, precisely calibrated, and fully operational according to factory specifications and local safety standards. This critical initial step lays the groundwork for seamless, trouble-free operation.

- Intensive Operator and Maintenance Training: To empower your team, we conduct thorough, hands-on training programs for your operational and maintenance personnel. This covers safe operation protocols, efficient production techniques, routine maintenance procedures, basic troubleshooting, and effective utilization of the automated control system. A well-trained team is crucial for maximizing the plant’s performance and minimizing avoidable downtime.

- Prompt and Responsive Technical Support: Our dedicated technical support team is available to address any operational queries, technical challenges, or performance issues that may arise. We offer multiple channels for support, including phone, email, and remote diagnostics where applicable. For complex issues, our expert technicians are dispatched for timely on-site intervention, ensuring minimal disruption to your production schedule.

- Guaranteed Availability of Genuine Spare Parts: We maintain a substantial inventory of genuine batching plant parts at our strategically located depots. This commitment to spare parts availability ensures that critical components can be supplied quickly, minimizing lead times for repairs and reducing costly downtime. All our spare parts are manufactured to the same stringent quality standards as the original components, guaranteeing perfect fit, optimal performance, and continued reliability.

- Proactive Maintenance and Servicing Programs: We offer flexible, tailor-made routine maintenance contracts and preventative servicing schedules. Regular inspections, lubrication, calibration checks, and wear-part replacements proactively identify and address potential issues before they escalate into major breakdowns. This proactive approach significantly extends the plant’s operational lifespan, maintains peak efficiency, and optimizes the total cost of ownership.

- Comprehensive Warranty Coverage: All concrete batching plants supplied by Silver Steel Mills come with a robust warranty, providing clients with peace of mind and underscoring our confidence in the superior quality, engineering, and reliability of our products.

Customization Options: Precision-Engineered to Your Unique Blueprint

Silver Steel Mills recognizes that the blueprint for success varies with each project. Our commitment to delivering bespoke solutions is reflected in our extensive customization capabilities for our concrete batching plant range. Our engineering and design teams collaborate intimately with clients to craft plants that precisely align with their unique operational demands, specific site conditions, and budgetary parameters.

Our comprehensive customization options include:

- Tailored Production Capacities: While we offer standard capacity models, we can engineer plants to meet precise hourly concrete output requirements, ensuring optimal resource allocation and avoiding over or under-capacitation.

- Optimized Aggregate Storage and Feeding: Options for varying numbers and capacities of aggregate bins, including linear bins or skip hoppers, to accommodate diverse aggregate types and volumetric requirements. Choice between efficient belt conveyor systems (for higher capacities and continuous feeding) or skip hoist systems (for compact layouts and cost-effectiveness).

- Flexible Cement and Powder Storage Solutions: Integration of single or multiple cement silos of varying capacities (e.g., 50-ton, 100-ton, 150-ton), including mobile concrete silo options for portable plants. We can also incorporate dedicated silos for fly ash, slag, or other supplementary cementitious materials.

- Specific Mixer Technologies: Selection of the ideal mixer type (e.g., twin-shaft for rapid, homogeneous mixing; planetary for specialized concrete like precast or high-performance mixes) and its precise capacity to ensure desired concrete consistency and production rate.

- Advanced Automation and Control Features: From standard fully automatic PLC systems to highly customized software interfaces with advanced reporting, remote monitoring capabilities, SCADA integration, and enterprise resource planning (ERP) system compatibility.

- Integrated Admixture Dosing Systems: Inclusion of highly accurate liquid or powder admixture dispensing systems for producing specialized concrete mixes with enhanced properties.

- Environmental Control Enhancements: Options for advanced dust collection systems (bag filters), noise reduction enclosures, and sophisticated water recycling systems to ensure compliance with environmental regulations and promote sustainable operations.

- Temperature Management Systems: Integration of chilling plants for cooling water in hot climates or heating systems for aggregates and water in cold environments to ensure optimal concrete setting and strength development.

- Specialized Components: Addition of features like aggregate pre-screening units, weighbridges for truck weighing, or sophisticated material handling systems to streamline operations further.

This meticulous attention to detail and ability to customize ensures that when you acquire a batching plant for sale in Pakistan from Silver Steel Mills, you are not merely purchasing a piece of machinery. You are investing in a precision-engineered, perfectly integrated concrete production ecosystem, optimized for your operational excellence and long-term success.

Navigating the Cost Landscape: A Comprehensive Analysis of Batching Plant Prices in Pakistan

Understanding the batching plant price in Pakistan is a pivotal step in the acquisition process. However, to make a truly informed decision, one must look beyond the quoted purchase price and delve into the multifaceted factors that contribute to the overall investment and the long-term total cost of ownership. Silver Steel Mills is committed to transparency, offering premium-quality concrete batching plants that represent superior value at competitive market rates, ensuring a robust return on your investment.

Core Determinants of Batching Plant Price in Pakistan

The price of a batching plant is not static; it is a dynamic figure shaped by a complex interplay of engineering specifications, material choices, technological sophistication, and market forces. Key factors include:

- Production Capacity (m³/h): The Primary Price Driver:

- Direct Correlation: The most significant factor influencing cost is the plant’s theoretical output capacity, measured in cubic meters per hour (m³/h). A higher capacity plant (e.g., 120 m³/h vs. 40 m³/h) necessitates larger and more robust mixers, aggregate bins, conveyors, silos, and more powerful motors, all of which substantially increase manufacturing costs and, consequently, the sale price.

- Scalability: Smaller plants like a mini mobile concrete batching plant (20-30 m³/h) will naturally be more affordable, suitable for localized, smaller-scale projects. Mid-range plants (40-90 m³/h) cater to diverse construction needs, while large ready mix batching plant units (100-240 m³/h) command premium prices due to their scale and high-volume output capability.

- Plant Type and Mobility (Stationary vs. Mobile):

- Stationary Plants: These typically have a higher initial purchase price due to their larger size, more substantial components, and the requirement for permanent, reinforced foundations and extensive civil works. However, their higher capacity and greater durability for continuous operation often justify this higher upfront investment for large-scale, long-term projects.

- Mobile Concrete Batching Plant: While offering unparalleled flexibility and rapid deployment, the integrated design, specialized chassis, and quick assembly mechanisms of a portable concrete plant can sometimes result in a higher unit cost per cubic meter of capacity compared to a basic stationary setup. However, this is often offset by significant savings on foundation costs, relocation expenses, and faster project initiation. The mobile batching plant price reflects its inherent versatility.

- Level of Automation and Control System Sophistication:

- Manual/Semi-Automatic: These plants generally have the lowest batching plant price in Pakistan as they rely more on human intervention for weighing and control. However, they compromise on precision, consistency, and efficiency, leading to higher operational costs and potential quality issues.

- Fully Automatic: Plants equipped with advanced PLC-based control systems, industrial computers, real-time data logging, and comprehensive software offer superior accuracy, consistency, and reduced labor requirements. This technological sophistication adds to the initial cost but delivers significant long-term savings through minimized material waste, optimized energy consumption, and superior concrete quality. The investment in automation is often rapidly recouped through enhanced productivity and reduced errors.

- Mixer Type and Capacity:

- Twin-Shaft Mixers (e.g., JS Series): Highly efficient for homogeneous mixing, suitable for a wide range of concrete types and capacities. Considered a premium mixer type.

- Planetary Mixers: Ideal for specialized concrete (e.g., precast, high-performance, self-compacting) due to their intensive mixing action, but often more expensive and typically used in smaller, specialized plants.

- Drum Mixers: Less common in modern batching plants due to lower mixing efficiency and consistency compared to compulsory mixers, but can be found in very low-cost or older models. The capacity of the mixer (e.g., JS500 vs. JS1500) directly scales with the plant’s overall output and, consequently, its price.

- Aggregate Feeding System:

- Skip Hoist (Bucket Type): Common in smaller to medium capacity plants, more compact, and generally less expensive initially.

- Belt Conveyor: Preferred for higher capacity plants (over 60 m³/h) due to continuous, higher-speed feeding, but involves more complex civil work and a higher initial cost.

- Cement Silo Capacity and Number:

- The storage capacity of cement silos (e.g., 50-ton, 100-ton, 150-ton) directly impacts the price. Larger capacities and the inclusion of multiple silos (for different types of cement or fly ash) increase the overall investment. Options for a mobile concrete silo also factor into the overall mobile batching plant price.

- Brand Reputation and Manufacturer’s Credentials:

- Established manufacturers like Silver Steel Mills, known for their rigorous quality control, engineering prowess, and reliable after-sales support, often command a price that reflects their commitment to superior product quality and client success. While seemingly higher initially, this premium translates into reduced operational risks, lower maintenance costs, and a longer asset lifespan, offering far greater value than cheaper, unproven alternatives.

- Inclusion of Optional Features and Customizations:

- Any specific additions or modifications, such as advanced dust collection systems, water chilling/heating units, specialized admixture pumps, dedicated control cabins, additional aggregate bins, or specialized software modules, will naturally increase the overall concrete batching plant price in Pakistan. These options enhance functionality and efficiency but add to the initial outlay.

- Ancillary Costs:

- Freight and Logistics: Transportation costs from the manufacturing facility to the client’s site.

- Installation & Commissioning: Costs associated with professional setup and calibration.

- Civil Works: Costs for foundations, approach ramps, and site preparation (especially for stationary plants).

- Utilities: Costs for power connection, water supply, and possibly a generator for remote sites.

- Import Duties and Taxes: For imported plants, these can significantly inflate the final price. This is where locally manufactured plants like those from Silver Steel Mills offer a distinct advantage, avoiding substantial import levies.

Silver Steel Mills: Redefining Value in Pakistan’s Batching Plant Market

At Silver Steel Mills, our pricing philosophy is rooted in providing unrivaled value rather than simply the lowest batching plant price in Pakistan. Our unique position as an integrated steel manufacturer and batching plant producer allows us to offer a proposition that few competitors can match:

- Intrinsic Quality, Engineered Value: Our batching plants are built from the ground up using the highest grade steel, meticulously produced in our own mills. This vertical integration means we control the material quality at its source, translating into plants that possess inherent strength, exceptional durability, and extended operational lifespans. While our initial price reflects this superior quality, it directly reduces your long-term operational costs, downtime, and the need for frequent replacements – the hidden costs that often plague cheaper, lower-quality alternatives.

- Optimized Performance, Reduced Operating Costs: The precision engineering and advanced automation integrated into every Silver Steel Mills batching plant result in highly efficient operations. This means minimal material wastage, optimized energy consumption, and consistent, high-quality concrete production. These efficiencies directly contribute to lower operational expenses over the life of the plant, significantly boosting your project’s profitability and delivering a superior return on investment.

- Comprehensive Lifecycle Support, Mitigated Risk: Our commitment to extensive after-sales service, readily available genuine batching plant parts, and expert technical support minimizes the risk of costly breakdowns and prolonged downtime. This comprehensive support network ensures your investment remains productive and profitable, providing peace of mind that is invaluable.

- Local Manufacturing Advantage: Price and Accessibility: As a local Pakistani manufacturer, Silver Steel Mills offers significant advantages. We circumvent high import duties, currency fluctuations, and protracted international shipping times associated with foreign-made plants. This allows us to provide more stable and competitive pricing, faster delivery, and more accessible support and spare parts, all contributing to a more favorable total cost of ownership for a concrete batching plant in Pakistan.

- Transparent and Tailored Quoting: We believe in complete transparency. Our sales team works closely with you to understand your specific needs, providing detailed proposals and transparent quotations that break down the batching plant price in Pakistan based on your chosen specifications and optional features. We help you understand where every rupee is invested and the value it delivers.

While a superficial comparison of initial prices might sometimes favor an inferior product, a comprehensive analysis of the total cost of ownership – factoring in durability, efficiency, maintenance, downtime, and lifespan – unequivocally positions Silver Steel Mills’ batching plants as the most economically sound and strategically advantageous choice for any serious construction enterprise in Pakistan. Investing in a Silver Steel Mills batching plant is an investment in unparalleled concrete excellence and sustained operational profitability.

Batching Plant for Sale in Pakistan: Your Definitive Guide to Acquisition and Silver Steel Mills’ Supremacy

The quest for a dependable batching plant for sale in Pakistan represents a pivotal moment for any construction company, contractor, or ready-mix concrete supplier aiming to elevate their operational efficiency and secure consistent concrete quality. The market abounds with choices, from the compact agility of a mini mobile concrete batching plant to the robust output of a large-scale stationary unit. Navigating this landscape demands a sharp focus on engineering integrity, operational reliability, and unwavering post-purchase support. This section will guide you through the process of acquiring a batching plant in Pakistan, while highlighting why Silver Steel Mills stands as the undisputed premier choice.

Pathways to Acquisition: Where and How to Procure Your Batching Plant

For prospective buyers of a concrete batching plant in Pakistan, several distinct procurement avenues exist:

- Direct from Manufacturers (The Silver Steel Mills Advantage):

- Benefits: Purchasing directly from a reputable manufacturer like Silver Steel Mills offers an unparalleled array of benefits. You receive a brand-new, cutting-edge plant, often custom-built to your exact specifications. This path guarantees a full manufacturer’s warranty, direct access to comprehensive after-sales support (including installation, training, and troubleshooting), and readily available genuine batching plant parts. It also ensures direct communication with the engineering and production teams, facilitating customization and addressing specific technical queries.

- Silver Steel Mills’ Uniqueness: Our integrated steel manufacturing capability means you’re investing in a plant where the foundational materials are meticulously controlled from their source. This directly translates to superior durability and performance that outsourced components cannot match.

- Authorized Dealers and Distributors:

- Benefits: Many international and some local manufacturers operate through a network of authorized dealers. These dealers can offer sales, local installation, and sometimes limited support services. They can be a convenient option for accessing certain brands.

- Considerations: While convenient, ensure the dealer offers comprehensive and timely after-sales support directly or through the manufacturer. The pricing might also include a dealer margin.

- Online Marketplaces and Classifieds:

- Platforms: Websites such as batching plant in Pakistan OLX or other industrial equipment classifieds often list both new and used batching plant for sale options.

- Benefits: Can offer lower initial batching plant price in Pakistan, especially for used equipment.

- Risks: Purchasing through these channels carries inherent risks. The condition of used concrete plant for sale can be highly variable, often lacking a warranty, and reliable after-sales support can be scarce. Thorough professional inspection is crucial to avoid hidden defects, costly repairs, and significant downtime. For new plants listed, verify the legitimacy of the seller and the manufacturer’s warranty.

- Auctions and Liquidations:

- Benefits: Occasionally, industrial equipment, including batching plants, may be available through auctions, potentially at highly competitive prices due to distressed sales.

- Risks: These sales are typically “as-is, where-is,” meaning the buyer assumes all risks regarding the equipment’s condition and functionality. Extensive expertise is required to assess the plant’s true value and potential repair costs.

- Rental Options (For Short-Term Needs):

- Benefits: For short-duration projects, or to pilot the operational benefits of a batching plant without a significant capital outlay, some suppliers offer a concrete batching plant on rent or a mobile batching plant for rent.

- Considerations: While flexible, rental costs can accumulate quickly for longer projects, making outright purchase a more economical long-term solution.

The Undeniable Superiority of Silver Steel Mills for Your Batching Plant Acquisition

When the objective is to secure a batching plant that represents the pinnacle of engineering, durability, and operational excellence, Silver Steel Mills unequivocally stands as the paramount choice for buyers in Pakistan. Our advantages are not merely superficial; they are deeply ingrained in our manufacturing ethos and comprehensive client support.

- Manufacturing Sovereignty and Unrivaled Steel Quality:

- Unlike many competitors who procure steel from external, often varied sources, Silver Steel Mills leverages its identity as a premier steel manufacturer. This means every critical structural component of our concrete batching plant is fabricated from high-grade steel produced within our own facilities. This direct control ensures:

- Consistent Material Properties: Each batch of steel meets rigorous standards for tensile strength, hardness, and metallurgical purity, providing an unshakeable foundation for your plant.

- Optimized Performance: The inherent quality of our steel allows our batching plants to withstand extreme operational stresses, vibrations, and abrasive materials over prolonged periods, directly translating to an extended lifespan and reduced wear.

- Mitigation of Supply Chain Risks: Our in-house production minimizes dependency on external steel markets, ensuring more stable pricing and timely delivery, a distinct advantage over competitors who might face import delays or fluctuating material costs.

- Unlike many competitors who procure steel from external, often varied sources, Silver Steel Mills leverages its identity as a premier steel manufacturer. This means every critical structural component of our concrete batching plant is fabricated from high-grade steel produced within our own facilities. This direct control ensures:

- Precision Engineering and State-of-the-Art Fabrication:

- Our batching plants are not merely assembled; they are precision-engineered. Our design teams utilize advanced computational tools for structural analysis and design optimization, ensuring robust and efficient layouts.

- Our manufacturing facilities are equipped with the latest CNC machinery, automated welding robots, and precision cutting tools. This technology guarantees millimeter-perfect fabrication of every component, leading to seamless assembly, minimized operational tolerances, and superior overall plant performance.

- Tailored Solutions for Pakistan’s Unique Context:

- Our profound understanding of Pakistan’s diverse climatic conditions, prevalent aggregate types, and specific logistical challenges informs the design of every Silver Steel Mills batching plant. This localization ensures optimal performance, minimal operational issues, and enhanced longevity within the country’s unique environmental and industrial framework.

- Whether you require a robust concrete batching plant in Islamabad to handle specific climate variations or a high-capacity batching plant in Pakistan Karachi for demanding urban projects, our solutions are inherently optimized.

- Comprehensive Product Portfolio for Every Scale:

- From compact and easily transportable mobile concrete batching plant units for remote or short-term projects to powerful stationary ready mix batching plant solutions for continuous, high-volume production, Silver Steel Mills offers a complete spectrum. We ensure that your specific production needs are met with the most efficient and cost-effective solution.

- Unwavering After-Sales Support: Your Partner in Longevity:

- Our commitment to client success extends far beyond the sale. We provide an unparalleled after-sales support system that includes:

- Expert On-Site Installation and Commissioning: Ensuring your plant is set up correctly and calibrated for peak performance.

- Thorough Operator Training: Empowering your team with the knowledge and skills to operate and maintain the plant effectively.

- Prompt Technical Assistance: A dedicated team ready to provide remote or on-site support to minimize downtime.

- Guaranteed Genuine Spare Parts Availability: Minimizing repair delays with readily accessible, high-quality replacement parts.

- Proactive Maintenance Programs: Extending your plant’s lifespan and optimizing its efficiency through scheduled servicing.

- Our commitment to client success extends far beyond the sale. We provide an unparalleled after-sales support system that includes:

- Transparent Pricing and Long-Term Value Proposition:

- While our batching plant price in Pakistan reflects the premium quality and advanced engineering of our products, we are committed to transparent pricing that represents exceptional long-term value. Investing in a Silver Steel Mills batching plant is an investment in reduced operational costs (due to efficiency and minimized downtime), lower maintenance expenses, and a significantly extended asset lifespan. This comprehensive value proposition ensures a superior return on investment compared to cheaper alternatives that often entail higher hidden costs over time.

The Silver Steel Mills Acquisition Journey: A Seamless Path to Concrete Excellence

Engaging with Silver Steel Mills for your batching plant acquisition is a client-centric, meticulously structured process designed for seamless execution and your ultimate satisfaction:

- Initial Consultation and Comprehensive Needs Analysis:

- Your journey begins with an in-depth discussion with our team of sales engineers and technical experts. We delve into your project’s specific requirements: desired concrete output, types of concrete mixes, site constraints, logistical considerations, budgetary parameters, and long-term operational goals. This thorough understanding forms the bedrock of our tailored recommendation.

- Customized Solution Proposal and Detailed Design:

- Based on the comprehensive needs assessment, we meticulously craft a customized proposal. This includes recommending the optimal batching plant model (stationary, mobile concrete batching plant, compact), its precise specifications, level of automation, and any necessary customization options. We provide detailed technical drawings, performance specifications, and a transparent, itemized quotation detailing the batching plant price in Pakistan.

- Precision Manufacturing and Stringent Quality Assurance:

- Upon your approval, your batching plant enters our state-of-the-art manufacturing facility. Leveraging our in-house steel production, every component is fabricated with unparalleled precision using advanced CNC machinery and automated welding systems. Throughout the entire manufacturing cycle, rigorous multi-stage quality control checks are performed, culminating in a comprehensive functional test of the complete plant to ensure it meets our exacting standards before dispatch.

- Efficient Delivery, Installation, and Commissioning:

- We manage the streamlined and secure transportation of your batching plant components to your designated construction site. Our highly skilled technicians then proceed with the professional installation and commissioning. This involves meticulous assembly, precise calibration of all weighing and control systems, and thorough testing to ensure the plant is fully operational and performing optimally.

- Empowerment Through Training and Seamless Handover:

- Before the final handover, our experts conduct intensive, hands-on training sessions for your operational and maintenance teams. This covers safe operation protocols, efficient batching procedures, routine preventive maintenance, and basic troubleshooting techniques. Our goal is to empower your personnel to confidently and effectively manage your new Silver Steel Mills batching plant.

- Enduring After-Sales Partnership:

- Our commitment does not end with handover. Silver Steel Mills prides itself on forging long-term partnerships. Our dedicated after-sales support system remains readily accessible for technical assistance, provision of genuine batching plant parts, and ongoing maintenance support, ensuring the sustained peak performance and longevity of your investment.

Whether your ambition is to launch a new ready mix concrete enterprise, significantly expand existing production capacities, or require the agile deployment of a portable concrete batch plant for a specific project, Silver Steel Mills offers a complete, reliable, and value-driven solution. Our dedication to superior quality, exemplified by our in-house steel manufacturing, positions us as the undisputed leader in providing high-performance batching plants in Pakistan.

Frequently Asked Questions (FAQs) about Batching Plant Prices and Acquisitions in Pakistan

Understanding the nuances of batching plant price in Pakistan and the overall acquisition process is crucial. Here, we address some of the most frequently asked questions to provide clarity and empower you to make informed decisions when considering a batching plant for sale in Pakistan from Silver Steel Mills.

Q1: What is the primary factor driving the batching plant price in Pakistan?

A1: The most significant factor is the production capacity (measured in cubic meters per hour, m³/h). Higher capacity plants require larger components, more powerful motors, and more complex systems, leading to a higher manufacturing cost and thus a higher selling price. Other major factors include the plant type (stationary vs. mobile), level of automation, and mixer type.

Q2: How does the “in-house steel manufacturing” by Silver Steel Mills affect the batching plant price and value?

A2: Silver Steel Mills’ in-house steel manufacturing allows us to control the quality of the raw material from its source. This translates to superior, consistent quality steel for all structural components, leading to exceptionally durable and long-lasting batching plants. While the initial batching plant price in Pakistan reflects this premium quality, it offers significant long-term value by reducing maintenance costs, minimizing downtime, and extending the operational lifespan of the plant, ultimately providing a higher return on investment.

Q3: Are mobile concrete batching plant units more expensive than stationary ones?

A3: The initial mobile batching plant price can sometimes be comparable to or slightly higher than a stationary plant of similar capacity due to their integrated, portable design and specialized chassis. However, mobile plants offer significant cost savings in terms of civil works (less foundation required), reduced transportation costs for concrete, and faster setup/relocation, which can lead to a lower total project cost, especially for distributed or short-term projects.

Q4: Why should I invest in a fully automatic concrete batching plant when manual ones are cheaper?

A4: While manual or semi-automatic plants have a lower initial batching plant price in Pakistan, a fully automatic plant (like those offered by Silver Steel Mills) provides unparalleled precision in weighing and mixing, consistent concrete quality, significantly reduced labor costs, minimal material wastage, and comprehensive data logging capabilities. These advantages lead to higher efficiency, superior concrete quality, and a faster return on investment in the long run by eliminating errors and maximizing productivity.

Q5: What are the hidden costs associated with a cheaper, lower-quality batching plant for sale?

A5: Hidden costs in cheaper, lower-quality plants often include frequent breakdowns and costly repairs due to inferior materials and fabrication, high maintenance expenses, significant downtime leading to project delays and penalties, higher material wastage due to inaccurate batching, reduced concrete quality necessitating rework, and a shorter overall operational lifespan. These factors can quickly erode any initial savings.

Q6: Does Silver Steel Mills offer customization options that can influence the batching plant price?

A6: Yes, Silver Steel Mills offers extensive customization options, including varying capacities, aggregate bin configurations, cement silo types and sizes (including mobile concrete silo), different mixer types, specific feeding systems (skip hoist or belt conveyor), advanced automation features, and environmental control enhancements. Each customization is priced transparently and allows you to tailor the plant precisely to your operational and budgetary requirements.

Q7: What kind of after-sales support can I expect when I buy a concrete batching plant from Silver Steel Mills?

A7: Our after-sales support is comprehensive and enduring. It includes professional on-site installation and commissioning, intensive operator training, prompt technical assistance (remote and on-site), guaranteed availability of genuine batching plant parts, and options for routine maintenance and servicing programs to ensure continuous optimal performance.

Q8: How long does it typically take for a batching plant to be delivered and installed by Silver Steel Mills?

A8: Delivery and installation timelines vary based on the specific batching plant model, customization requirements, and site conditions. However, as a local manufacturer, Silver Steel Mills offers significantly faster delivery and installation compared to international suppliers, circumventing long shipping times and complex import logistics. Our team will provide an estimated timeline during the quotation process.

Q9: Can Silver Steel Mills provide a batching plant in Pakistan Karachi or a concrete batching plant in Islamabad?

A9: Yes, Silver Steel Mills supplies concrete batching plant solutions nationwide across Pakistan. Whether your project is in Karachi, Islamabad, Lahore, or any other region, our sales and technical teams are equipped to serve your needs, providing tailored solutions, efficient delivery, and localized support.

Q10: What is the benefit of buying a concrete batching plant locally from Silver Steel Mills rather than importing one?

A10: Buying locally from Silver Steel Mills offers numerous advantages: avoidance of significant import duties and taxes, protection from currency fluctuations, faster delivery times, easier access to genuine spare parts and technical support, reduced logistical complexities, and a direct contribution to Pakistan’s local economy and industrial growth.

Q11: How does the quality of the mixer affect the batching plant price?

A11: The mixer is the heart of the batching plant, and its quality, type (e.g., twin-shaft vs. planetary), and capacity significantly impact the overall price. High-quality mixers, like the JS series integrated into Silver Steel Mills’ plants, ensure superior concrete homogeneity, longer lifespan, and consistent performance, justifying their contribution to the higher batching plant price in Pakistan.

Q12: Is there a market for used concrete batching plant for sale in Pakistan?