Description

Your Guide to Batching Plants in Pakistan – The Silver Steel Mills Advantage

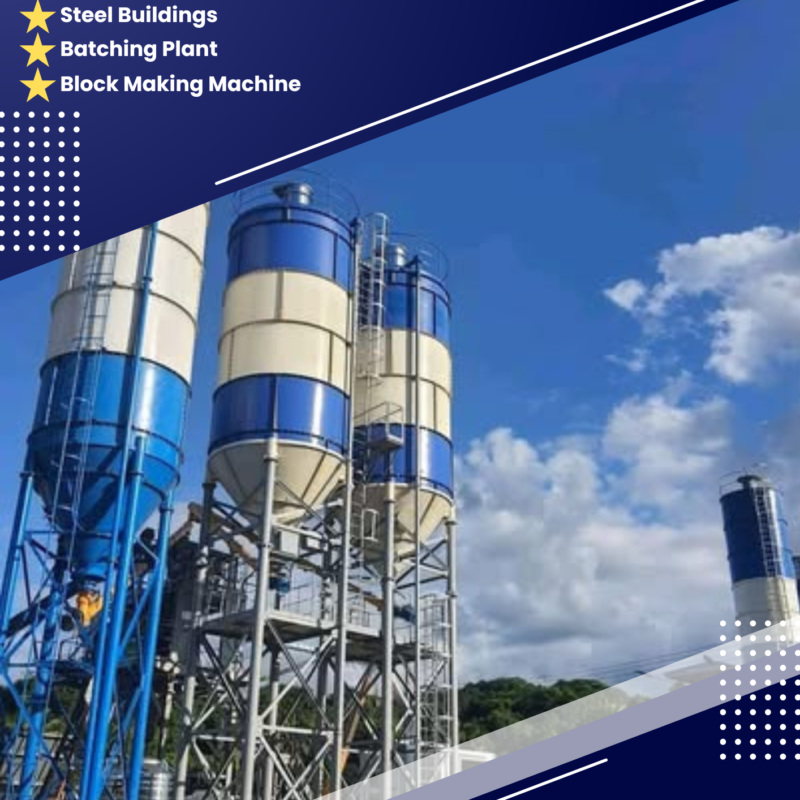

In the vibrant and ever-evolving construction landscape of Pakistan, the bedrock of every successful project, from towering urban complexes in Karachi to critical infrastructure connecting remote regions, is consistently superior concrete. The heart of this essential material’s production lies in the batching plant – a sophisticated hub where precision meets power. For discerning developers, contractors, and ready-mix suppliers across the nation, selecting the optimal concrete batching plant in Pakistan is not merely a procurement decision; it’s a strategic investment that dictates project timelines, cost-efficiency, and ultimately, structural integrity.

Silver Steel Mills stands as the undisputed vanguard in delivering cutting-edge batching plant solutions across Pakistan. Our unique vertical integration, stemming from our advanced in-house steel manufacturing, empowers us to forge equipment that is not only high-performing but also inherently robust, resilient, and engineered for the demanding realities of Pakistani construction. This comprehensive guide will meticulously explore the crucial considerations for acquiring a batching plant for sale in Pakistan, delve into the intricacies of concrete batching plant price in Pakistan, and illuminate why Silver Steel Mills remains the premier choice for achieving unparalleled concrete excellence.

The Pivotal Role of a Modern Batching Plant in Pakistan’s Construction Renaissance

Pakistan’s ambitious development agenda, encompassing the expansion of smart cities like Islamabad, extensive road networks, dams, and housing initiatives, places immense pressure on the construction supply chain. In this dynamic environment, a state-of-the-art concrete batching plant becomes indispensable for:

- Unwavering Quality Control: Ensuring every cubic meter of concrete adheres precisely to the specified mix design, crucial for structural strength and longevity, especially given Pakistan’s diverse climatic conditions and seismic considerations.

- Optimized Efficiency & Speed: Delivering high volumes of consistent concrete on demand, thereby accelerating project schedules and minimizing costly delays associated with manual mixing or unreliable external suppliers.

- Cost Management: Reducing material wastage through accurate batching, optimizing labor, and minimizing transportation costs, directly impacting the overall ready mix concrete price in Pakistan.

- Environmental Responsibility: Modern batching plants incorporate features like dust suppression and efficient water usage, aligning with growing environmental standards and sustainable construction practices in Pakistan.

Navigating the Landscape: Types of Batching Plants Offered by Silver Steel Mills

Understanding the various types of batching plants is paramount for making an informed decision. Silver Steel Mills provides a comprehensive array, each designed to cater to specific project scales and logistical requirements:

- Stationary Concrete Batching Plants:

- Best Suited For: Large-scale, long-term infrastructure projects (e.g., major highway segments, large building complexes, mega industrial zones) demanding continuous, high-volume concrete production at a fixed location.

- Characteristics: These plants offer the highest capacities (e.g., from 60 m³/h up to 240 m³/h and beyond) and maximum stability, built for relentless operation. They require a dedicated foundation and more extensive setup.

- Silver Steel Mills Advantage: Our stationary batching plants are constructed with our superior, in-house manufactured steel, ensuring unmatched structural integrity, minimal vibration, and an extended operational life cycle, even under the most arduous conditions. They integrate advanced automation for precise control over large outputs.

- Mobile Concrete Batching Plants:

- The Epitome of Agility: A mobile concrete batching plant (also known as a portable concrete plant, mobile concrete plant, or portable batch plant) is engineered for unparalleled flexibility and rapid relocation.

- Ideal For: Linear projects like roads, bridges, irrigation canals, or sites with limited space, remote locations, or projects requiring frequent movement between construction phases. A mobile batching plant for sale offers exceptional strategic value.

- Key Benefits: Drastically reduced transit time for concrete, ensuring superior freshness and quality; significantly lower transportation costs for the finished product; minimal site preparation requirements; and incredibly fast setup/dismantling.

- Silver Steel Mills Advantage: Our mobile batching plants are built on robust, transport-friendly chassis systems using our high-strength steel. We offer a range from mini mobile concrete batching plant (25-35 m³/h) for smaller projects to higher capacity mobile concrete mixing plant units (up to 100 m³/h), ensuring a perfect fit for diverse needs. Each concrete portable batch plant is designed for quick “plug-and-play” deployment, often ready to produce concrete within hours. We also provide mobile concrete silo options to enhance their portability.

- Ready Mix Concrete Plants (Commercial Focus):

- Specialization: These are often stationary or large mobile plants primarily configured for commercial concrete suppliers who deliver ready-mix concrete to multiple construction sites via transit mixers.

- Silver Steel Mills Advantage: Our ready mix batching plant in Pakistan solutions are designed for continuous, high-volume production with robust components and advanced automation to handle diverse customer orders and strict quality specifications.

Why Silver Steel Mills is Pakistan’s Premier Partner for Batching Plants

When searching for a concrete batching plant for sale in Pakistan, the market presents various options, from imported machinery to used batching plant for sale listings (such as a batching plant in Pakistan OLX listing). However, for sustainable success and maximum return on investment, partnering with Silver Steel Mills provides distinct, unmatched advantages:

1. The Unbreakable Core: In-House Steel Manufacturing

This is our fundamental differentiator and the cornerstone of our product quality. Silver Steel Mills uniquely possesses the capability to produce the high-grade structural steel that forms the very foundation of every batching plant we manufacture.

- Intrinsic Material Superiority: We exercise complete control over the chemical composition and mechanical properties of our steel. This ensures unparalleled tensile strength, yield strength, and fatigue resistance, essential for components bearing immense loads and enduring constant vibration. Your batching plant will withstand Pakistan’s challenging climates and continuous operation for decades.

- Exceptional Durability and Longevity: Our custom-formulated steel, combined with advanced anti-corrosion treatments, provides superior resistance to rust and wear. This significantly extends the operational lifespan of your concrete batching plant, minimizing the need for costly replacements and reducing downtime, a critical factor often overlooked in used concrete plants for sale.

- Precision Fabrication: With our own steel, we achieve precise cutting, bending, and welding, leading to perfectly aligned components and robust overall construction. This precision ensures seamless assembly and optimal performance, whether it’s a large stationary plant or a small mobile concrete batch plant.

2. Cutting-Edge Engineering & Automation

Silver Steel Mills batching plants are a fusion of robust mechanics and intelligent control.

- Pinpoint Batching Accuracy: Our fully automatic PLC-based control systems, integrated with high-precision load cells for every material (aggregates, cement, water, admixtures), guarantee exact mix ratios. This not only ensures consistent, high-quality concrete but also drastically reduces material wastage, optimizing your batching plant in Pakistan price.

- Reliable Mixing Technology: We equip our plants with industry-leading mixers, primarily robust twin-shaft compulsory mixers, known for their rapid and homogeneous blending capabilities, critical for producing diverse concrete grades.

- Intuitive Operations: User-friendly interfaces allow for easy recipe management, real-time production monitoring, and detailed data logging for quality assurance and operational insights. This automation makes our concrete mixing plant for sale highly efficient.

3. Unrivaled Local Support and Value

Choosing Silver Steel Mills means more than just purchasing equipment; it’s entering a long-term partnership with a local leader.

- Cost-Effectiveness & Value: While the concrete batching plant price in Pakistan can vary, our direct manufacturing capabilities eliminate import duties and currency fluctuation risks, offering more stable and competitive pricing. The superior durability and efficiency of our plants translate into a significantly lower total cost of ownership and a faster return on your investment compared to cheaper, less reliable imports or the uncertainties of a concrete plant for sale used.

- Swift Installation & Training: Our expert teams ensure rapid installation and thorough training for your personnel, getting your batching plant operational quickly and efficiently.

- Guaranteed Spare Parts & Service: We maintain a readily available stock of genuine batching plant parts, ensuring minimal downtime for maintenance or repairs. Our dedicated after-sales support team is always available for technical assistance, ensuring continuous operation. This contrasts sharply with the challenges often faced with parts availability for Elkon concrete batching plant or other international brands in Pakistan.

- Flexible Solutions: Whether you need a mobile concrete batching plant for rent for a short-term project, or you’re specifically searching for a batching plant in Pakistan Karachi or concrete batching plant in Islamabad, we offer tailored solutions to meet your precise geographical and operational needs. We even offer avenues for clients interested in a portable concrete batch plant for rent or considering a truck mounted concrete batching plant for specialized projects.

4. Beyond Concrete: Holistic Construction Solutions

Silver Steel Mills doesn’t just stop at batching plants. We are a comprehensive provider of construction machinery, capable of integrating solutions for various aspects of your project. While this article focuses on concrete, it’s worth noting our expertise extends to other related equipment.

Understanding Batching Plant Price in Pakistan

The batching plant price in Pakistan is influenced by several factors:

- Capacity (m³/h): Higher output capacities naturally command higher prices due to larger components and more powerful systems. A mini mobile batching plant will be significantly less than a 120 m³/h stationary plant.

- Automation Level: Fully automatic plants with advanced control systems are more expensive than semi-automatic or manual variants but offer greater precision, efficiency, and labor savings.

- Mixer Type: The quality and type of mixer (e.g., twin-shaft vs. planetary) influence the cost.

- Ancillary Equipment: Features like mobile concrete silo units, advanced dust collection systems, water chilling units, or specific aggregate feeding mechanisms will affect the final mobile concrete batching plant price or overall ready mix concrete plant for sale cost.

- Manufacturer: Reputable manufacturers like Silver Steel Mills, who offer superior quality, comprehensive support, and proven reliability, provide value that extends far beyond the initial purchase price, unlike potentially cheaper but riskier options found for concrete plant for sale used.

The Silver Steel Mills Commitment: Building Pakistan, One Perfect Batch at a Time

At Silver Steel Mills, our vision extends beyond transactions; it’s about empowering Pakistan’s growth. We understand that every bridge, every building, and every road built with our concrete is a testament to quality and progress. Our batching plants are not just machines; they are instruments of national development, crafted with precision, powered by innovation, and supported by a commitment that lasts a lifetime.

Whether you’re a major contractor seeking a high-capacity stationary batching plant, or a dynamic firm in need of an agile mobile concrete batch plant for sale, Silver Steel Mills offers the perfect synergy of robust engineering, cutting-edge technology, and unparalleled local support. Forget the uncertainties of batching plant in Pakistan OLX listings or imported equipment; invest in a partnership that guarantees excellence.

Transform your concrete production capabilities today. Contact Silver Steel Mills for a personalized consultation and a detailed quotation that aligns with your project’s unique demands and budget.

Visit our official website: silversteelmills.com

In Pakistan’s quickly evolving building trade, the demand for environment friendly and dependable concrete manufacturing options has by no means been increased. Concrete batching vegetation have emerged as important gear, guaranteeing constant high quality and well timed supply of concrete for numerous tasks. This information delves into the specs, use instances, advantages, options, pricing, FAQs, and a shopping for information for concrete batching vegetation in Pakistan.

What’s a Concrete Batching Plant?

A concrete batching plant is a facility the place numerous components like cement, water, aggregates, and components are mixed to provide concrete. These vegetation be sure that the concrete produced meets particular necessities, providing consistency and high quality important for building tasks.

Kinds of Concrete Batching Crops in Pakistan

1. Stationary Concrete Batching Crops

Best for large-scale tasks with lengthy durations, these vegetation are mounted installations that provide excessive manufacturing capacities. They’re generally utilized in infrastructure tasks like highways, bridges, and dams.

2. Cellular Concrete Batching Crops

Designed for tasks that require frequent relocation, cell vegetation are compact and may be simply transported. They’re appropriate for distant areas and tasks with shorter durations.

3. Compact Concrete Batching Crops

These vegetation supply a stability between mobility and manufacturing capability. They’re appropriate for city building tasks the place house is restricted.

Specs of Concrete Batching Crops

Batching Plant in Pakistan – Concrete Batching Plant in Pakistan | Silver Steel Mills

When it comes to high-performance, durable, and reliable batching plants in Pakistan, Silver Steel Mills (SSM) stands out as a trusted name. As Pakistan’s infrastructure and real estate sectors continue expanding, the demand for premium-quality concrete batching plants has grown significantly. Silver Steel Mills proudly manufactures and supplies state-of-the-art concrete batching solutions, engineered specifically for Pakistan’s construction environment.

Why Choose Silver Steel Mills for Concrete Batching Plants?

Silver Steel Mills specializes in supplying batching plants that are designed for both small and large-scale projects. From commercial high-rise buildings to infrastructure developments like roads and bridges, SSM’s batching plants ensure consistent concrete quality, efficiency, and long-term reliability.

-

Locally manufactured with global quality standards

-

Competitive pricing tailored for Pakistani businesses

-

Full support, from installation to after-sales service

-

Customization options for height, capacity, and discharge settings

Introduction to Concrete Batching Plants in Pakistan

A concrete batching plant is a specialized facility where cement, aggregates, water, and other components are mixed to create high-quality concrete. Unlike manual mixing, batching plants ensure precise proportions, fast production, and uniform output.

In Pakistan, these plants are essential for:

-

Housing societies

-

Commercial complexes

-

Infrastructure projects under CPEC

-

Road and bridge construction

-

Industrial zones

Silver Steel Mills provides batching plants suitable for all these applications with features customized for local climate and construction demands.

JS500 Concrete Batching Plant: Silver Steel Mills’ Flagship Model

One of SSM’s most popular models is the JS500 concrete mixer—ideal for forming a simple concrete batching plant when paired with PLD series batching machines.

✔️ JS500 Overview:

The JS500 is a twin-shaft horizontal forced type mixer that can handle:

-

Dry hard concrete

-

Plastic concrete

-

Flowing concrete

-

Lightweight aggregate concrete

-

Various types of mortar

It is engineered for flexibility, efficiency, and durability, with the option to work standalone or as part of a fully equipped HZS25 concrete batching plant setup.

JS500 Technical Specifications:

| Parameter | Detail |

|---|---|

| Model | JS500 Twin Shaft Mixer |

| Discharging Capacity | 500 Liters |

| Drum Capacity | 800 Liters |

| Productivity | ≥25 m³/h |

| Max Aggregate Size | ≤40/50 mm (Cobble/Crushed Stone) |

| Mixing Time | 72 Seconds |

| Transport Dimensions | 3050×2530×2680 mm |

| Working Dimensions | 4461×3050×4180 mm |

| Weight | 4,000 kg |

| Mixing Blade Speed | 35 r/min |

| Number of Mixing Blades | 2×7 |

| Mixing Motor Power | 18.5 kW |

| Winch Motor Power | 5.5 kW |

| Water Pump Motor Power | 1.1 kW |

| MOQ | 1 Set |

| Delivery Time | 7–30 Days |

Key Features and Advantages of Silver Steel Mills’ JS500 Batching Plant

-

✅ High mixing evenness with a short mixing cycle, guaranteeing high reliability and minimal breakdown.

-

✅ Hydraulic discharge with adjustable door angles and optional manual operation.

-

✅ High wear-resistant chromium-manganese alloy plates and blades for extended service life.

-

✅ Multi-sealing shaft end system prevents leakage and ensures continuous operation.

-

✅ Fully copper motors, speed reducers, and hydraulic systems sourced from China’s top brands.

-

✅ Manufactured using national standard steel for durability and strength.

-

✅ Available with discharge heights of 1.5 m or 3.8 m for flexible application.

-

✅ Backed by ISO and SGS certifications with 11 technical patents.

Applications of Silver Steel Mills’ Batching Plants

-

Housing Projects and Housing Schemes

-

Industrial Construction Projects

-

Road and Bridge Construction

-

Precast Concrete Plants

-

Municipal and Government Contracts

Why Silver Steel Mills?

-

🏢 Pakistani Manufacturing, Pakistani Support: Locally made plants mean faster delivery and lower costs.

-

🛠️ Full Technical Support: From installation and commissioning to operator training and spare parts availability.

-

💡 Custom Solutions: Tailored batching plant configurations to match your project’s specific concrete production needs.

-

🔄 Proven Performance: SSM batching plants are trusted in major national projects.

How to Place an Inquiry

Interested in purchasing a batching plant from Silver Steel Mills? The process is simple:

-

Contact Silver Steel Mills via the website or direct phone.

-

Share your project details and capacity requirements.

-

Receive a custom quote along with delivery and installation schedules.

-

Confirm your order and initiate production.

Final Thoughts: The Best Batching Plant in Pakistan for Modern Construction

For reliable, efficient, and long-lasting concrete batching plants in Pakistan, Silver Steel Mills’ JS500 model is a proven choice. Whether you’re a real estate developer, contractor, or industrial builder, partnering with SSM ensures your concrete production is backed by engineering excellence.

✅ Explore Pakistan’s top-quality batching plant solutions with Silver Steel Mills today.

For more information and to get a quote, visit silversteelmills.com or contact the sales team directly.

| Mannequin | Sort | Capability (m³/h) | Mixer Sort | Mixture Storage | Cement Silo Capability | Management System |

|---|---|---|---|---|---|---|

| S25 | Stationary | 25 | JS500 | 3×3 m³ | 50-100 tons | Absolutely Computerized |

| S50 | Stationary | 50 | JS1000 | 3×8 m³ | 100-200 tons | Absolutely Computerized |

| S75 | Stationary | 75 | JS1500 | 4×7 m³ | 100-200 tons | Absolutely Computerized |

| S60 | Cellular | 60 | JS1000 | 4×7 m³ | 100-200 tons | Absolutely Computerized |

| S90 | Stationary | 90 | JS1500 | 4×15 m³ | 200-300 tons | Absolutely Computerized |

| S120 | Stationary | 120 | JS2000 | 4×15 m³ | 200-300 tons | Absolutely Computerized |

Use Instances of Concrete Batching Crops

-

Infrastructure Tasks: Highways, bridges, and tunnels require massive volumes of concrete, making stationary vegetation supreme.

-

Residential and Business Buildings: Cellular and compact vegetation are appropriate for city building tasks.

-

Distant Building Websites: Cellular vegetation may be transported to distant areas, guaranteeing well timed concrete provide.

-

Precast Concrete Manufacturing: Batching vegetation are utilized in factories producing precast concrete parts.

Advantages of Utilizing Concrete Batching Crops

-

Constant High quality: Automated processes guarantee uniform mixing, resulting in constant concrete high quality.

-

Time Effectivity: On-site concrete manufacturing reduces transportation time and delays.

-

Price-Efficient: Reduces dependency on third-party suppliers, resulting in value financial savings.

-

Customization: Combine designs may be tailor-made to particular challenge necessities.

Options of Trendy Concrete Batching Crops

-

Automated Management Methods: Superior PLC programs for exact management over mixing processes.

-

Excessive-High quality Mixers: Twin-shaft mixers guarantee thorough mixing of components.

-

Mud Assortment Methods: Environmental compliance by environment friendly mud assortment.

-

Modular Design: Ease of set up and relocation.

Pricing of Concrete Batching Crops in Pakistan

The price of concrete batching vegetation varies primarily based on capability, options, and model.

-

HZS25: Roughly PKR 2.5 million to PKR 3.5 million.

-

HZS50: Roughly PKR 4.5 million to PKR 6 million.

-

HZS75: Roughly PKR 6.5 million to PKR 8 million.

-

HZS90: Roughly PKR 8.5 million to PKR 10 million.

-

HZS120: Roughly PKR 11 million to PKR 13 million.

Word: Costs are indicative and will fluctuate primarily based on configurations and market circumstances.

FAQs

Q1: What’s the distinction between stationary and cell batching vegetation?

A: Stationary vegetation are mounted installations appropriate for long-term tasks, whereas cell vegetation may be relocated and are perfect for short-term or distant tasks.

Q2: How a lot house is required for putting in a batching plant?

A: House necessities fluctuate primarily based on the plant’s capability and sort. A small plant like HZS25 could require round 15,000 sq. ft, whereas bigger vegetation want more room.

Q3: What’s the supply time for a batching plant in Pakistan?

A: Supply instances can vary from 4 to eight weeks, relying on the producer and customization necessities.

This fall: Are spare components available in Pakistan?

A: Sure, most respected producers have native distributors or service facilities guaranteeing the provision of spare components.

batching plant in pakistan concrete batching plant in pakistan concrete batching plant worth in pakistan concrete batching plant on the market in pakistan used batching plant on the market cell concrete batching plant concrete plant on the market cell batching plant moveable concrete plant cell concrete plant moveable concrete batch plant batch plant on the market cell batching plant on the market cell concrete batch plant on the market used concrete vegetation on the market moveable batch plant used concrete batch plant on the market moveable concrete batch plant on the market